Quick and Accurate Mortises

A plunge router and router box make this method of cutting mortises simplicity itself.

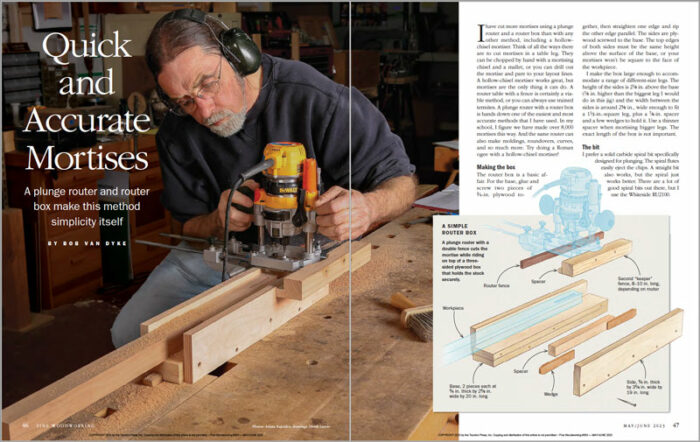

Synopsis: There are plenty of ways to cut mortises, but in Bob Van Dyke’s shop and in the classes he teaches, a plunge router with a router box is the go-to method. With this simple process, a plunge router with a fence cuts the mortise while riding on top of a three-sided box that holds the stock. Here he shows you how to make the box and how to use it.

I have cut more mortises using a plunge router and a router box than with any other method, including a hollowchisel mortiser. Think of all the ways there are to cut mortises in a table leg. They can be chopped by hand with a mortising chisel and a mallet, or you can drill out the mortise and pare to your layout lines. A hollow-chisel mortiser works great, but mortises are the only thing it can do. A router table with a fence is certainly a viable method, or you can always use trained termites. A plunge router with a router box is hands down one of the easiest and most accurate methods that I have used. In my school, I figure we have made over 8,000 mortises this way. And the same router can also make moldings, roundovers, curves, and so much more. Try doing a Roman ogee with a hollow-chisel mortiser!

Making the box

The router box is a basic affair. For the base, glue and screw two pieces of 3 ⁄ 4-in. plywood together, then straighten one edge and rip the other edge parallel. The sides are plywood screwed to the base. The top edges of both sides must be the same height above the surface of the base, or your mortises won’t be square to the face of the workpiece.

I make the box large enough to accommodate a range of different-size legs. The height of the sides is 2-1 ⁄ 8 in. above the base (1 ⁄ 8 in. higher than the biggest leg I would do in this jig) and the width between the sides is around 2-5 ⁄ 8 in., wide enough to fit a 1-1 ⁄ 2-in.-square leg, plus a 7 ⁄ 8-in. spacer and a few wedges to hold it. Use a thinner spacer when mortising bigger legs. The exact length of the box is not important.

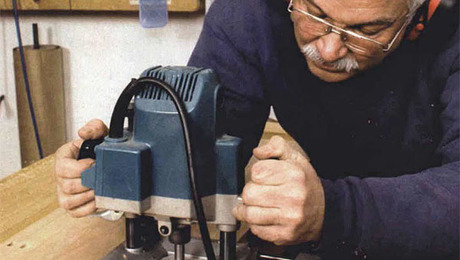

The bit

I prefer a solid carbide spiral bit specifically designed for plunging. The spiral flutes easily eject the chips. A straight bit also works, but the spiral just works better. There are a lot of good spiral bits out there, but I use the Whiteside RU2100.

Building the router box

Construction doesn’t get much easier than this: four pieces of plywood glued, clamped, and screwed together.

|

|

Using the box

Once you build your box, lay out the mortise on a test, or “setup” leg the same width and thickness as the real leg and long enough to fit securely in the box (12 in. is enough). Put your setup piece into the box against the right side. Use two wedges on the left side to hold it in place. If you set the leg on the left side with the wedges on the right and the fence on the right, the inconsistent pressure on the wedge will result in an inconsistent mortise. Setting the workpiece on the right, the fence on the right, and the wedges on the left negates this problem; the distance between the fence and the mortise will never change.

Most legs get two mortises—one in each of two adjacent faces— and the fence setting is usually the same for both. After you’ve set the fence and cut the first mortise, you cut the second by simply turning the leg end-for-end. Because the piece must be turned, I don’t bother setting stops to control the length of mortises.

—Contributing editor Bob Van Dyke runs the Connecticut Valley School of Woodworking.

Photos: Anissa Kapsales.

Drawings: Derek Lavoie.

For the full article, download the PDF below:

|

Safe, accurate handheld routing |

|

Video: Router Table Fundamentals – Mortises |

|

From the archive: In search of the right mortising technique |

Log in or create an account to post a comment.

Sign up Log in