STL291: Bandsaw tension secrets revealed!

Not really—but Mike, Amanda, and Ben discuss their methods for kind of dialing it in, as well as prefinishing strategies, and how they use computer-aided design in their personal woodworking.Question 1:

From Eric:

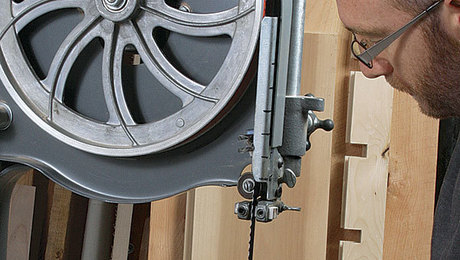

Is there a good method for setting bandsaw blade tension consistently? I remember once reading about how much it should deflect sideways with the upper guide set so far above the table. As a woodshop teacher, I do lots of adjusting to our band saws as students are learning how to set the upper guard vs. the adjustments not to touch. Recently we had a 3/4″ blade break starting at the teeth and heading to the rear of the blade. The crack didn’t go all the way through the blade, staying connected at the rear, and the blade was very bowed towards the teeth side. Is this a sign of over-tension?

|

Tension Bandsaws without a GaugeLearn how to find the proper tension just by pressing on the blade with your fingertip (with the bandsaw unplugged). |

|

Tool review: EZtension Bandsaw Tension GaugeRollie Johnon reviews a clever bandsaw tension gauge. |

|

Shopmade Tension GaugeBuilt-in bandsaw gauges are notoriously inaccurate. Here’s an inexpensive tool that eliminates guesswork |

Question 2:

From Valentin:

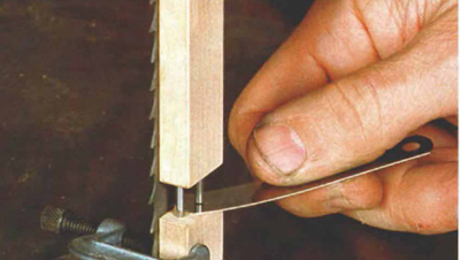

I have a question about the order in which you guys prefer to do your surface prep, glue up, and finishing. It seems to me like a dumb question but whenever I get to the end of a project, I hesitate in the chronology of those last steps. The logical way would be to sand the parts, glue them up, and then apply the finish, but I always want to finish them before gluing up, so I don’t have to deal with squeeze-out staining the bare wood and resand the piece once assembled. But what if I need to plane a joint flush after gluing up because one is a little proud over the other? What if I damage the surface during glue-up? I should mention that the pieces I do are generally pretty intricate and accessing some parts of the pieces aren’t easy. Also, I generally go towards Rubio monocoat as my default wood finish.

|

Finish While You BuildPre-finish parts and then control squeeze-out for a fast, flawless finish. |

Question 3:

From Jason:

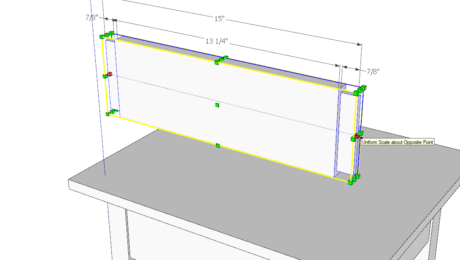

I often struggle with the design aspect of woodworking. Specifically, getting the proportions of a piece right. I usually make a horrendous sketch on scrap paper with a dull pencil just to get things straight in my mind on how they will fit together. But every few years I will render a bigger or more challenging project on Google SketchUp before trying to build it. I find it super helpful to dial in some of the proportions and get it looking right. Now I know this happened years ago, but I was quite surprised to realize that Google SketchUp is no longer free or even made by Google. It appears to have been purchased by a company called Trimble. In any case, I am curious if any of you use computer-aided design programs to mock up your pieces. If so, is there a particular piece of software you like? I am not computer savvy at all and struggle even with the very basic functions of sketch up. But it was worth the struggle sometimes to be able to see the piece before I built it. Since I only used it on rare occasions, I would prefer not to have to purchase software, but would be totally willing to if there was a good program out there that is user-friendly, for the technically challenged.

|

Scaling in SketchUpDave Richards is a fan of the scale tool, but not for everything. This short video shows a case where scaling wouldn’t be the best choice and another example of where it is a good choice. |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Another great podcast. These podcasts lead me to becoming an Unlimited member.

Mike's discussion about understanding the whole process and knowing what's important and what isn't was very informative.

Ben,

You caught my attention with using Fusion to design the headstock for your ukes. I REALLY need to learn that program!

Ben,

I'm still using SketchUp make from 2016. No issues.

Gary

Adding a comment to Jason's questions:

Google lost interest in SketchUp (it wasn't serving their needs) and in 2012 Trimble picked it up. It hasn't been "Google SketchUp" since June 1, 2012. There is now a free web-based version for hobbyists, and three versions, SketchUp Pro (desktop), SketchUp Go (web-based), and SketchUp for iPad for those who use it seriously and/or commercially.

Although no longer supported by Trimble, it is possible to find the installer for SketchUp 2017 Make with an internet search. I've heard that some folks have downloaded it without problems. The web services that SketchUp Make used haven't been supported for years and the web browser (Internet Explorer on Windows and an old version of Safari on Mac) haven't been getting security updates from their makers so iit would be wise to exercise caution if you go that way.

Jason, if you are interested in continuing with SketchUp there are free tutorials at learn.sketchup.com and their YouTube channel. There's the Design. Click. Build. blog here on the Fine Woodworking site.

As with woodworking tools in the shop it is possible to make very sophisticated projects with the basic tools in Sketchup.

-Dave

Log in or create an account to post a comment.

Sign up Log in