STL293: Camber Alert!

Megan Fitzpatrick joins Vic and Ben to discuss round vs. square dogs, drilling at an angle, plane iron camber, and the best material to use on a bathroom vanity.Question 1:

From Chris:

I have always wondered what is an easy way to keep your workpiece square on a drill press when you are drilling at an angle. With the head tilted, if you rotate the workpiece out of square to the head it throws everything off. Without the use of a laser set up to give you a square reference, how do you keep your X and Y axis square?

|

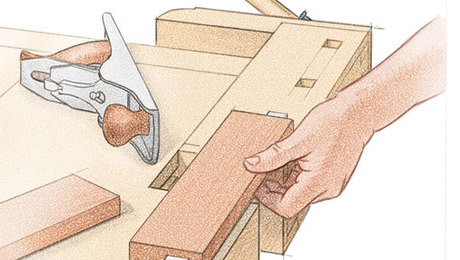

Two Jigs for the Drill PressCut mortises and angled holes with these easy-to-make jigs |

|

Tuning Your Drill PressHow to find and eliminate vibration, play and wobble |

Question 2:

From Nils:

I plan to build a bathroom vanity but I am concerned about wood movement in this rather harsh environment. When someone takes a shower, humidity levels and temperature rise abruptly, but only for a short period of time. Do these bursts of humidity and temperature have any effect on wood movement, or is the duration too short to be of any concern? Which materials would you recommend for such a build? Is solid wood the optimal choice? Or would a veneer on man-made sheet goods be more stable? I would be concerned about the de-lamination of my veneer.

|

Best Finish for Bathroom FurnitureI am making a cabinet for my bathroom. What’s the best finish to protect it against the rapid changes in heat and humidity that it will experience? |

Question 3:

From Charlie:

Hello shop talk! This is Charlie from Glenwood Springs, CO. I love your show and listen to you guys on my daily commute. My question is about creating a camber on plane irons. Do you guys only put a camber on your smoothing planes? From what I’ve learned using a honing guide, you tilt the blade slightly on the corners first and slowly fare it towards the center as you hone. Is there any advice you have as to how much you tilt the blade initially? How heavy of a camber is needed?

|

Camber: The Secret to Perfect PlaningCrown your smoothing plane blade, and say good-bye to sandpaper |

Question 4:

From Robert:

Hey guys, big fan, my names is Rob. I’m building a new workbench and have decided on a tail vice and traditional face vice. I have all the hardware and know how I’m going to assemble everything. My question is, if I use round dogs do I have to angle the holes the way you do if they were square dogs? How much? How can I achieve this post glue up/ assemble?

PS: I noticed that many tail vices have a flange at the far end, making it “L” shaped, but that doesn’t close tight to the apron. Is this not meant to be used as a face vice, or am I missing something?

|

Making Sense of VisesA user’s guide to the heart of the workbench |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Another great show folks.

I see a Fender Strat behind Vic which makes me wonder "What percentage of woodworkers are also musicians?" It seems that a lot of us are. Some even work at Fine Woodworking if I'm not mistaken.

Ken

Log in or create an account to post a comment.

Sign up Log in