Shopmade veneer trimmer

This simple DIY trimmer works well on hard and wavy veneer.

Excerpt from “Cutting Corners” in Fine Woodworking #9—Winter 1977

My commercial, foreign-made veneer trimmer works well on straight-grained veneers but not on irregular-grained wood. This trimmer is difficult to operate because the blade has to be set at a fixed depth; it is awkward to control when going over the veneer in several passes. Used in one pass, its cut is not perfectly straight and either splits the wood or follows the grain. This trimmer is not to be confused with a veneer saw, which works well, but for a perfectly flush cut (in matching veneers or making borders) sawn veneer must have a final sanding or planing in a wood jig.

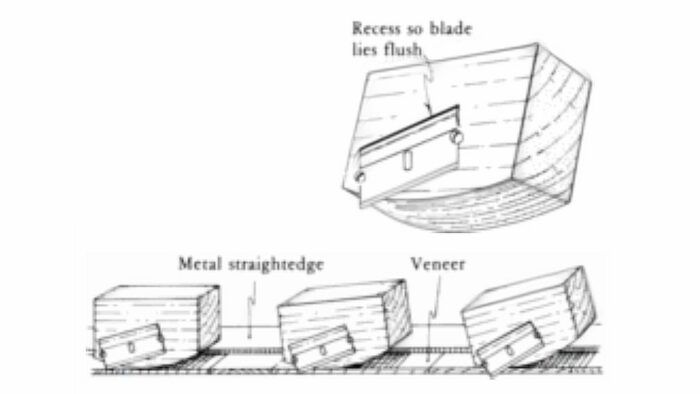

My own veneer trimmer costs almost nothing and for me, it works better. The advantage is that several passes can be made, lowering the blade a little each time by a slight hand movement. Thus it is easier to trim irregular grains and hard veneer. The 3/4-in.-wide block of wood keeps the blade perpendicular. Because of the curved bottom, each pass can cut more deeply. The curved bottom can be cut with a sabre saw, or on a power jigsaw with the table perfectly flat. Medium sandpaper glued or attached with double-faced tape to the bottom of a metal ruler makes a guide that will not slide on the veneer. I change blades frequently-one blade can be used twice by turning it around. Dimensions of the trimmer aren’t critical, but the bottom must be even, or it will stray away from the straightedge.

|

Essential router-table jigs: Veneer trimmerSee how a pair of crowned boards makes a jig that lets you joint perfect edges on a stack of veneers |

|

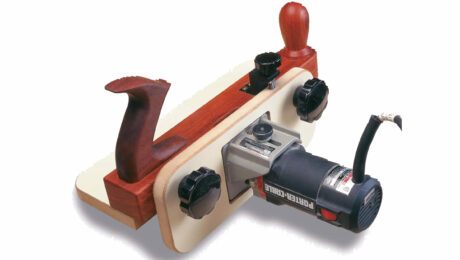

Shopmade trimmerSimple carriage steadies trim router to flush-cut plywood edge-bands |

|

How to bandsaw your own veneerTips for smooth slicing in any kind of wood |

Log in or create an account to post a comment.

Sign up Log in