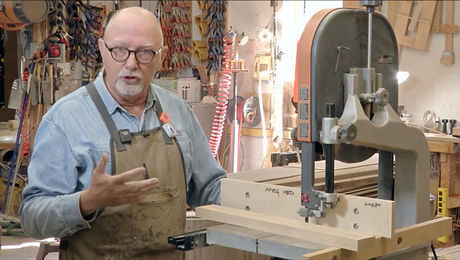

STL297: The hand tool you need to buy is a bandsaw

Gary Rogowski joins Vic and Ben to discuss adjusting hinges, using a chamfer bit for box miters, and making Queen Anne furniture without a bandsaw.Question 1:

From Mike:

I’ve bumped into an issue on several cabinets I’ve made, hoping you have some strategies. Even though I take great care to glue up my carcasses and doors flat and square, I sometimes end up with a door that’s slightly proud of the front of the carcass at the top or bottom (for an inset door). I use Mike’s technique for routing hinge mortises, no apparent issues there.

On a recent bookcase, I checked the carcass and each door on my table saw ‘surface plate’, and they were each within one playing card of dead flat. But when everything was together, I had a noticeable misalignment at the bottom (flush at the top).

Do you have any techniques for small hinge adjustments to reduce the gap? I’d rather not plane the door surface as that would disrupt the offsets between the rails and styles.

I used rare earth magnets at the top as catches, I could add another set at the bottom to bend the door into submission, but that feels clunky.

Question 2:

From Art:

I generally mill my wood to about ⅜-in. thick for box making. What are your thoughts about cutting box sides to length on a table saw/miter saw for dimensioning, and then using a router table with a 45-degree chamfer bit to introduce a predictable angle to them… eliminating a great deal if set-up time. The final step would be fine-tuning on a shooting board. This approach doesn’t get much discussion…. I’m guessing that there must be a reason.

Question 3:

From Greg:

I’ve been woodworking for about 5 years and although I’m a hobbyist I manage to log somewhere between 20 and 30 hours a week in the shop. I have a table saw, lunchbox planer, router, CMS, and a Carlyle Lynch-style lathe but don’t have a band saw because it’s both cost and space prohibitive. I like Queen Anne-style furniture but, because I don’t have a bandsaw, I find myself cutting curves with a pattern bit on the router. This works well enough most of the time but I’ve found that thicker stock (3” thick for cabriole legs) is hard on the bits (and probably the router) and ends up burning/tearing out the wood.

Lately, I’ve really enjoyed working with hand tools. What hand tools would you recommend I consider adding to my toolbox to do the job of a bandsaw?

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Glad to hear you stand up for that 14 inch Delta Bandsaw Ben! If you get some help finding a good one, it can be a joy!

"Jump into the 19th century!" I love it. Gary is The Man!

I love it! I usually listen to the podcast but today am watching on FWW. As Ben is reading the question about the best hand tool for cabriole legs, I'm watching Vic's and Gary's faces. Priceless!

Log in or create an account to post a comment.

Sign up Log in