How to add a wood floor to any workshop

An easy way to install high-performance wood flooring over concrete.

Compared to unforgiving concrete, a wood floor makes a shop much more friendly to the body. It also adds insulation and warmth, and is much less likely to damage dropped tools. Here’s an easy way to install a high-performance wood floor over concrete—one that’s solid enough to support heavy, rolling machinery. It will work in most shops, but you might need to trim your doors at the bottom if they open inward.

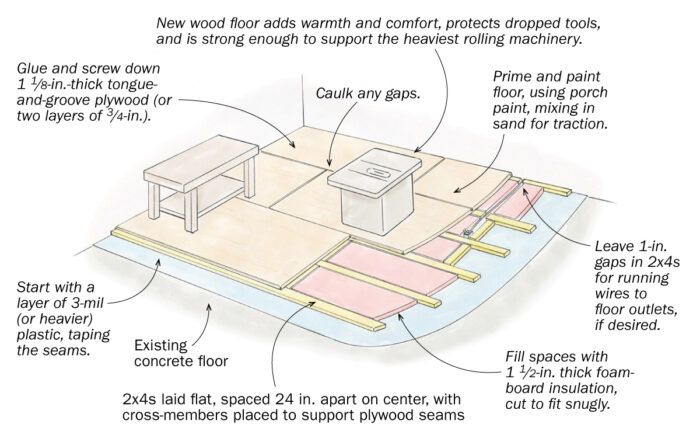

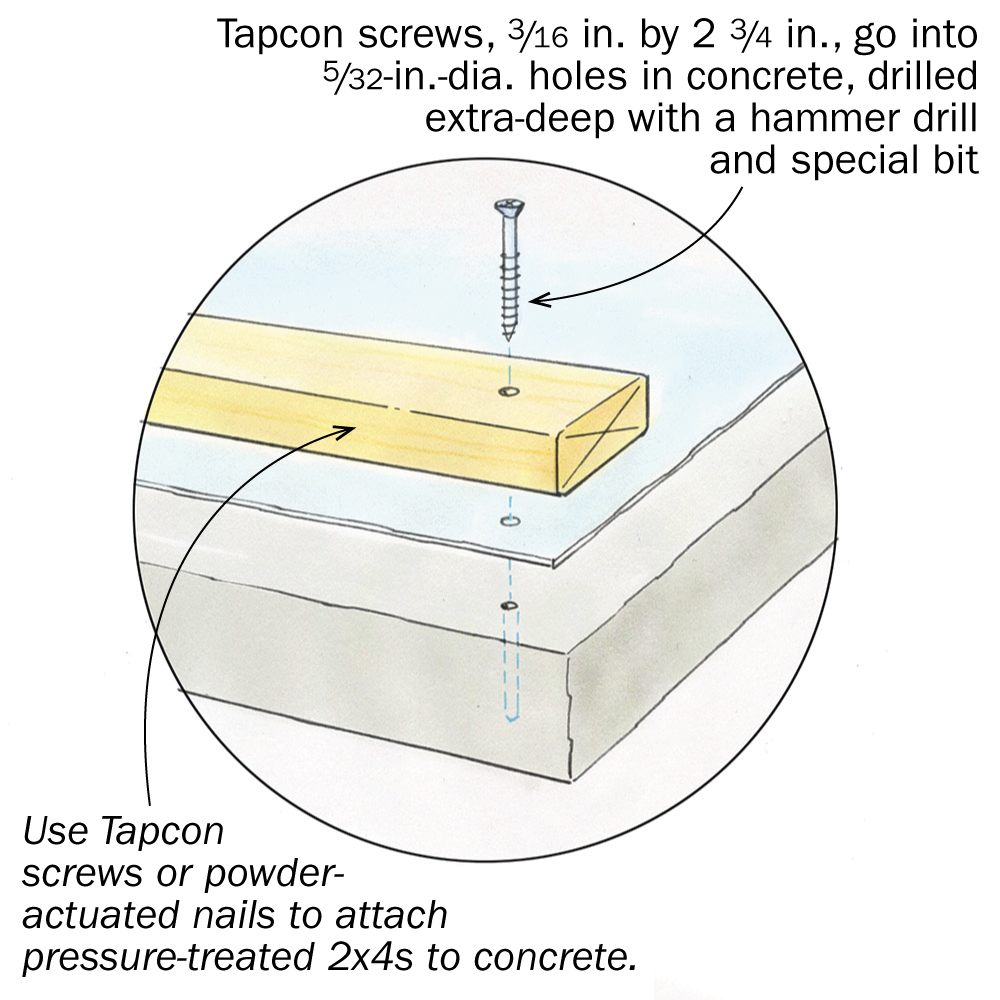

Installing this wood floor is as easy as making lasagna. Start with a layer of heavy plastic to prevent moisture from wicking up from the porous slab. Screw down treated 2x4s on their faces, placing them 2 ft. apart on center so the plywood seams will land on them correctly; place cross-members to do the same. Fill the spaces between the 2x4s with rigid foamboard insulation, and then glue and screw down thick tongue-and- groove plywood sub flooring, which will be the new shop floor.

A variety of finishes will work, but I went with two coats of tough paint, designed for porches, mixing in sand to add traction, an important safety feature.

Installing the floor offered a chance to keep power cords out from underfoot. I did this by leaving gaps in some of the 2x4s to allow wiring to pass through, and then installing outlet boxes in the plywood. My new wood floor makes the shop a much warmer and more welcoming place to be.

—MICHAEL RICCO, Kalamazoo, Mich.

Illustrations by Dan Thornton

From Fine Woodworking issue #307

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Woodriver Rechargeable Desiccant Bag

Comments

For my 18'x 18' shop, I price this out at about $500. That's cheaper than the other suggestion on FW, which is to use subflooring tiles with insulation built in. That comes to about $800, I think. Correct my math?

This kind of floor is wonderful for a workshop. I have 22 years in tactical comm which busted up my knees and lower back pretty good. I put this foam floor in my shop last fall and it has been the best thing ever! Compared to concrete there is no comparison, my knees feel great and my feet don’t freeze. I think my shop is 5-10 degrees warmer. I ran 240 and 120 circuits to where my big machines are, so there are no cables to trip on. My only caution is if you have seriously heavy tools you should to put in 2x6 or 2x8 blocking where the machines will go to support the machine’s weight. Just do it, you can thank me later.

Edit: I used OSB for the floor, I don’t recommend it for high traffic areas. Also, OSB has a lot of grooves that sawdust and dirt can collect in. I used two coats of primer and two coats of floor paint and it didn’t fill in the grooves. I may put down hardboard flooring in the future.

Log in or create an account to post a comment.

Sign up Log in