STL308: Cold weather woodworking

Larissa Huff joins Vic and Ben to discuss working in the cold, dovetail layout, fancy tape measures, and if spokeshaves are in fact worth it.Question 1:

From Vaibhav:

I love the show and listen regularly. I have an uninsulated garage where I do woodworking. I use a propane tank top heating element to heat while I’m working but other than that, it’s frigid in the Chicago winter.

As a beginner, I wanted to know what my blind spots are regarding working in the cold. What precautions do I need to take regarding wood movement, finishing, etc? I don’t know what I don’t know.

I have a table saw, jointer, planer, miter saw, drill press, and a few hand planes.

Question 2:

From Scott:

When cutting dovetails, do you lay out all four dovetails then cut, or lay out one set and cut, lay out another set, and cut?

Question 3:

From Mike:

I’m building a bow front cabinet in ash, with the front door rails and a drawer front below formed from bent laminations. I cut the plies from the edge of a wide 12/4 flat-sawn board, so the show faces have a nice quarter-sawn look.

I kept track of the plies so I could keep everything sequential. My question is, would you prefer to use three sequential plies ‘out of order’ as the show faces of the rails and drawer, and get very consistent grain on those pieces, or just use the plies as they appeared in the board?

There’s a noticeable difference in grain as it progresses through the board, so each part will have its own character if I use the plies in the order they were cut. I’m not too concerned about the grain matching exactly on the edges since they won’t be very visible. So it comes down to preference for consistency of grain on the face vs a more natural grain progression. Either is fine, but I’m curious to hear your thoughts.

Question 4:

From Jose:

I am currently working on a very basic side table/stool that essentially consists of a small panel with 3 legs that are attached with through round tenons. I am currently working on shaping the top panel and rounding some edges. See the picture below for an example of what I am aiming for. I was able to rough out the shape with a bandsaw (I recently purchased my first bandsaw and I’m still getting used to operating it and getting nice clean cuts). However, I am now looking to get the final shape and profile. I’ve attempted to use my orbital sander with 80 grit sandpaper but it’s slow going and I’ll spend a small fortune on sandpaper as it tears from the edges rather quickly.

Any idea on what would be the best way to do this? It seems like a spokeshave might be the tool but I don’t own one. Is it worth the investment (I’ve been looking at the Veritas spokeshave or LN Boggs)? I’m limited on shop time right now (I’ve got a newborn) so the idea of messing with an old Stanley doesn’t sound fun. Or may I be able to accomplish the same with my low-angle block plane?

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Turning to Hoadley "Understanding Wood" (aka, the bible), the coefficient of thermal expansion for wood is 2 parts per million per °F parallel to the grain (sorry Vic, but that's how Hoadley writes it), 10 times that perpendicular. This is totally dwarfed by any changes in moisture content. Any cracking, such as Larissa's experience, come from moisture change. A cold shop heated up each day will have very low humidity and will lower the EMC of the wood, so there are impacts of a cold shop, but they are not thermal expansion.

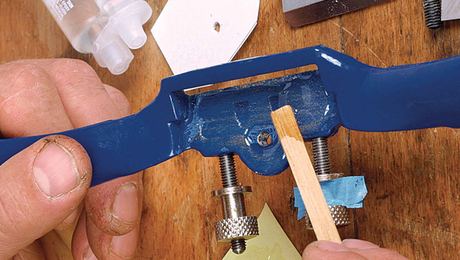

Here are two simple jigs for making dovetails on the bandsaw. The sloped ramp is for the pins. A corresponding angled guide is for cutting the tails. All spacing is freehand. Very simple to build.

Vic - I'll send a video if the use isn't obvious enough.

Add me to the list of people who'd love to see some video content on cutting dovetails with the band saw - whether it's Vic or Larissa or someone else. I'd also be interested in seeing what Vic comes up with for cutting pins at the band saw. I'd been under the impression that part of the difficulty was that the average band saw table doesn't tilt quite far enough for the correct angles on the pins - hence the need for a secondary sled of some sort. Recently I'd also seen it mentioned that cutting pins first (sorry if that triggers Vic! ;) ) would allow for easy layout of the tails, which could then be cut to suit on the band saw. Either way, looking forward to what y'all come up with!

Log in or create an account to post a comment.

Sign up Log in