Using jam chucks at the lathe

Darryl Jones shows an example of how a jam chuck can overcome work-holding challenges at the lathe.

There are times in woodturning when the need arises for “creative” or customizable work holding at the lathe. There are commercially available solutions such as flat jaws, soft jaws, vacuum chucks, etc., but these tools have limitations. Cost can be one such limitation; it may be difficult to justify the cost for a likely single-use solution. A jam chuck is a great option, because it is infinitely customizable and constructed of scrap material you already own. A jam chuck holds objects on the lathe utilizing a wood-on-wood friction joint. This wood-on-wood joint will not mar a finished piece so it can also be used on projects that need touching up.

I was recently commissioned to make a classroom set of spinning tops for my wife’s co-worker. While making these tops, I was able to use jam chucking to make more efficient use of materials. I started with a 1-1/2 in. square by 6-in.-long blank, which allowed me to make three tops from each section, leaving a scrap just big enough for another top. That last piece usually presents an issue as it would necessitate working too close to the chuck jaws. I was able to use a jam chuck to reverse-mount the spinning top and finish the bottom. Jam chucking can be a very accurate way of remounting workpieces.

A spinning top must be accurately turned around a single center point to work well. I started by shaping and texturing the top side of the top.

There is not enough room between the spinning top and the chuck jaws for shaping, texturing, and parting.

Jam chuck to the rescue!

To use a jam chuck, mount a block of scrap in the chuck and bore a hole through the center with a spindle gouge (a drill bit could be used also) to make room for the handle of the top. Cut a recess with a parting tool that will just fit the diameter of the outer edge of the top. The recess will also provide good registration as it holds the spinning top around the top corner, gripping the edge and referencing the face. This fit needs to be very tight and may take a few tries to get it just right, but it is worth it.

Insert the spinning top handle end first and tap it in with the butt end of your chisel. At this point, the spinning top can be shaped and decorated.

|

|

After removing the jam chuck with the spinning top attached, a dowel or compressed air can be used to push the spinning top out of the tight-fitting jam chuck.

Or, reusable soft jaws might be better

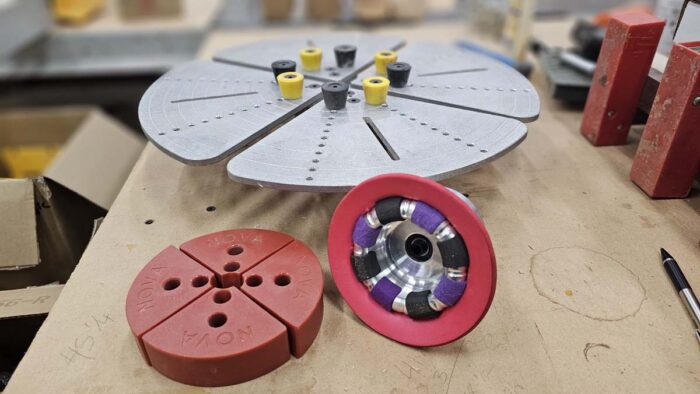

As a bonus, an adjustable jam chuck could be made by creating DIY soft jaws for your chuck.

|

|

The example described here is only one of the many uses for a jam chuck. Jam chucks can be used for large and small projects, everything from jewelry pendants to bowls. The next time you are presented with a difficult holding situation, get creative and use a jam chuck.

-Darryl Jones is a Fine Woodworking Ambassador. He enjoys empowering others through teaching and sharing knowledge and techniques. His social media handle is Dread Knot Woodshop (YouTube, Instagram) because he believes that we are all capable of more than we realize. Hence the tagline “Dread Knot and Make Something.”

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Comments

Great Article

Log in or create an account to post a comment.

Sign up Log in