STL310: Yep, it’s a woodworking podcast!

Vic and Ben welcome a new host into the mix and discuss resawing, easy-to-build knock-down benches, how one Dr. can stop overusing their table saw, and the wealth of knowledge left to us by Bruce Hoadley.Question 1:

From Steve:

My question: Often when I’m resawing boards, the thinner boards coming off of the bandsaw bow, even though the original board was perfectly joined flat. If they were thicker, I could just flatten them on the jointer. But they are now so flexible, I cannot push them across the jointer without removing the bow, so they come out still bowed and just thinner. What is a good method to get them flat on one face for final thicknessing?

Question 2:

From Bob:

When you adjust for the thickness of the shavings to be taken by a plane, you adjust the opening in front of the blade wider or narrower. Is there any measurement for the size of the opening in front of the blade compared to the shaving thickness, or do you just eyeball it?

Question 3:

From Mitch:

I am hosting an instrument maker/restoration workshop in my shop this summer. I have lots of space and a budget. We need to build an additional 8-10 benches. These do not need to be incredible everyday benches but something sturdy and useful for a week. There is a chance this workshop will happen every summer, so having something I can “knock down” would be great too. The minimum dimensions are something similar to those generic woodworker benches from Harbor Freight or Grizzly: say 2′ wide by 4′ long. Do you have any recommendations? Could be a quick and cheap build or an easy to assemble kit.

|

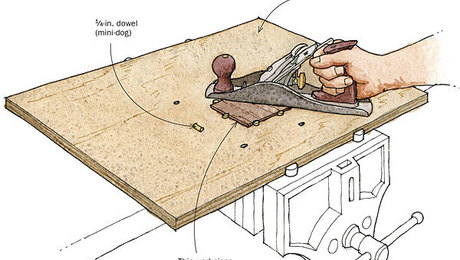

From Popular Woodworking:

|

Question 4:

From Andy:

As an amateur woodworker and “professional” physician, I have been making routed letter benches for new infants at the hospital. The bench simply consists of a top piece and 2 leg pieces. The basic process consists of cutting a 15-degree angled groove in an 18-inch piece of 2X10 softwood acquired at Home Depot. The making of each groove is done with multiple passes on my contractor table saw. Although employing push sticks, the table saw blade remains unguarded and each groove requires approximately ~12 passes. So far I have now made more than 200 benches but the demand is high. The top bench piece is not light and must be pushed fully through the blade without kickback. After making 10 benches in a work session there is some boredom and fatigue. I am concerned that there should be a safer way to make these grooves. I have attached some pictures that will hopefully outline the issue.

|

|

Link to video for 3D printed Jig:

https://www.instagram.com/reel/C3EW6P4LDfg/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA==

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@finewoodworking.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

Nice to see Amanda back..

Regarding the question on a knockdown workbench, I'd like to point out another option: the Moravian workbench. It assembles and disassembles faster than any other that I have seen. It may be on the light side, but sandbags should help with that.

https://youtu.be/9IWhe_mbFzg?si=k9tNi7YimKg8zcs8

Ben - I'm a long time listener in my car. Many times you reference pictures or tools, and I can never find them when I get home. For example in this episode Amanda's 3d printed jig, and the Dr.'s letter bench. Can you let me know where you post them. If your not, it would really add to the quality of the podcast if you could - Thanks.

We try and post as much as we can remember too here on the show notes page. We'll get those up.

I'm glad that Vic met Bruce Hoadley before he (Hoadley) died. If he had met him after he died, that would be kind of creepy.

Log in or create an account to post a comment.

Sign up Log in