Shopmade tansu hardware

Len Cullum demonstrates how to make tansu hardware, including all the plates and corner braces out of sheets of copper.

Certain types of tansu, made to be moved around frequently, would sometimes have their joinery reinforced with corner braces and strapping hardware. Tansu hardware was commonly made from iron, but many smaller pieces used copper. I chose copper for the tansu in my article (“Traditional Tansu,” p. 52). Iron hardware can be purchased in the States, but copper hardware is difficult to find outside Japan, and I decided to make my own. Although this is Master Class, I wouldn’t call myself a master of this–just a guy who fumbles around and finds ways to solve for x. Once I figured out the path, however, the processes were surprisingly simple and the results were extremely gratifying.

Certain types of tansu, made to be moved around frequently, would sometimes have their joinery reinforced with corner braces and strapping hardware. Tansu hardware was commonly made from iron, but many smaller pieces used copper. I chose copper for the tansu in my article (“Traditional Tansu,” p. 52). Iron hardware can be purchased in the States, but copper hardware is difficult to find outside Japan, and I decided to make my own. Although this is Master Class, I wouldn’t call myself a master of this–just a guy who fumbles around and finds ways to solve for x. Once I figured out the path, however, the processes were surprisingly simple and the results were extremely gratifying.

In this article:

- Strapwork

- Bending tansu hardware by hand

- Using a brake

- Warabite drawer pulls

- Bending and fixing the bails

- Finger pulls for the doors

Len Cullum has the blanks for his tansu hardware cut with a water jet.

Thankfully, he shared his files with us so you can send

them to a fabricator and do the same.

Right-click here to download the zip file containing DXF files

Which finish?

My early meetings with tansu were with antiques, and to me there was something just fantastic about their wear and damage and patina. It gave them a warmth and life that captivated me. Much later, on a trip to Japan, I saw a brand new tansu, and it left me a little cold. While the craftsmanship was in every way exquisite, it just didn’t speak to me in the same way those old, well-used ones did, and it occurred to me that my love of tansu had just as much to do with their entropy as it did with their proportions and designs. That’s why I chose to use raw copper for the hardware on this piece. Traditionally, it would be treated with a coat of urushi lacquer and then heated to produce a glossy brown finish. I left mine unfinished to allow the visual aging of the piece to proceed unabated. If my client hadn’t requested an oil finish, I would have left the wood on this piece untreated as well.

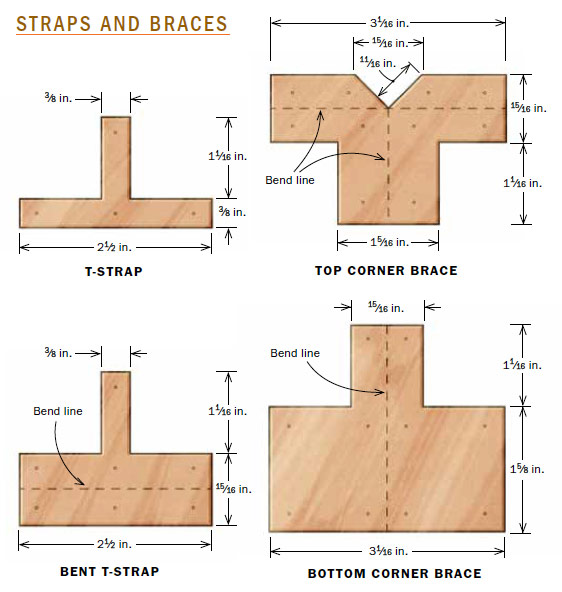

Strapwork

I used 22-gauge copper sheet to make all the corner braces and strapping. While I originally planned to use snips and cut the blanks out by hand, I really struggled to keep the copper from curling, and once it did curl, to get it flat again. My solution was to have the blanks cut with a water jet. It was costly—about $200—but I justified the cost by having four 12-in. by 18-in. sheets stacked and cut at once; this provided me with enough parts for half a dozen similar tansu cabinets.

Once the blanks were cut, the processing was pretty simple: Drill the nail holes, form the corner pieces using a small pan brake, then file and sand the edges smooth. Lastly, polish away the tarnish left by the cutting process.

Drill for nails. Plates and braces are affixed with escutcheon nails. With the protective plastic sheet still on the copper blank, lay out the holes and mark each one with a nail punch. Then bore the holes at the drill press with a hardwood block for backup.

|

|

Abrade the bracing. After drilling, remove the plastic and flat-sand the hardware with 400-grit paper on an MDF sanding block. Then file the edges slightly round.

Bending tansu hardware by hand

|

|

If you’re using a hand seamer to make the bends, place the workpiece so the bend line is just shy of the seamer’s jaw, and bend upward. Try marking and bending test pieces beforehand to get a feel for the process.

The hand brake creates a rounded corner. To square it off a bit, clamp the workpiece to a square-edged anvil and shape it using a hardwood caul and a hammer.

Clean the copper. Before installing the hardware, polish its surfaces.

Nail it. Cullum used 1⁄4-in.-long #18 solid copper escutcheon pins to nail on the copper hardware. Solid copper pins are sold in Japan, but are hard to come by in the United States. Brass pins, easier to find, look different initially, but match the copper more closely as they patina over time.

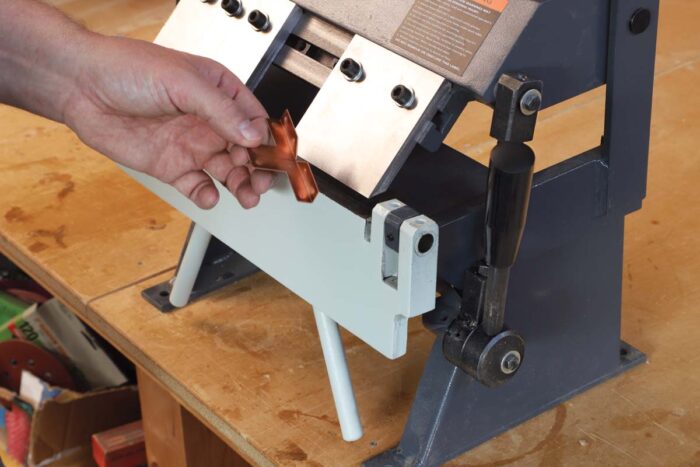

Using a brakeA benchtop pan brake makes the folds crisp, clean, and easy.

|

Traditional tansu-style warabite drawer pulls

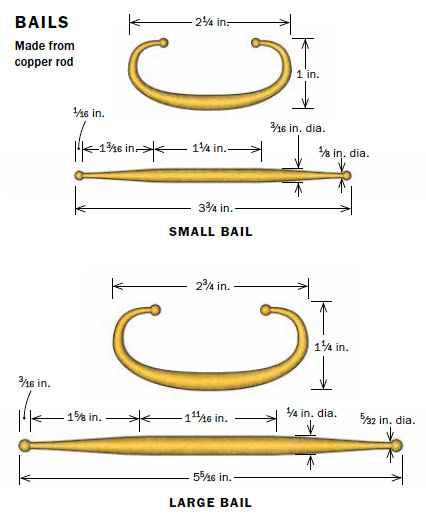

Drawers on traditional tansu often have bails made in a style called warabite, for its resemblance to the curling shape of bracken shoots. My original plan was to hot-forge warabite bails from copper rod with a hammer. But after much practice and many attempts, it became clear I’d need several more months of practice before I could approach the consistency I would need to make them all match. So I tried a different route: At a strip sander, I sanded rod stock to a double-tapered shape, then bent it over a form.

Drawers on traditional tansu often have bails made in a style called warabite, for its resemblance to the curling shape of bracken shoots. My original plan was to hot-forge warabite bails from copper rod with a hammer. But after much practice and many attempts, it became clear I’d need several more months of practice before I could approach the consistency I would need to make them all match. So I tried a different route: At a strip sander, I sanded rod stock to a double-tapered shape, then bent it over a form.

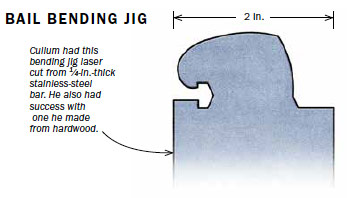

I started by measuring some antique handles and making a wooden bending jig. Because I was thinking about working copper the same way I worked steel, I heated up a copper rod and tried it out. The jig worked well, but the hot copper burned into the wood much more quickly and deeply than I had expected. Unless I wanted to remake the jig repeatedly, I’d need a different solution. So I decided to have a bending form laser cut from a bar of 1⁄4-in.-thick stainless steel. This worked great, but soon after, I realized that the copper worked nicely cold, so I could have used the wood form after all. (On the upside, I now have a bending jig that will outlast me.)

For the smaller drawers, I made bails from lengths of 3⁄16-in.-dia. copper rod; for the large bottom drawer, I used 1⁄4-in.-dia. rod. After cutting the rod to length, I made reference marks for shaping. Then, using a 1-in.-wide belt on the strip sander, I roughed out the double taper, frequently checking the narrow diameter with calipers and leaving a knob at each end of the rod. Once all the tapers were shaped, I cleaned up the knobs on the strip sander. I hand-sanded the bails to 400-grit, and polished them with maroon and gray abrasive pads.

Bending and fixing the bails

Then it was off to the bending jig. Hook one knob into the opening and bend the bar over the curve; reverse and repeat. While 3⁄16-in. bails cold-formed nicely, the 1⁄4-in. ones were a little too stiff to bend tightly to the form, so they needed to be annealed to make them more ductile. To anneal them, I used a propane torch, heated them to cherry red, and then quenched them in water. Quenching steel hardens it, quenching copper makes it softer. After that they bent around the jig beautifully.

Then it was off to the bending jig. Hook one knob into the opening and bend the bar over the curve; reverse and repeat. While 3⁄16-in. bails cold-formed nicely, the 1⁄4-in. ones were a little too stiff to bend tightly to the form, so they needed to be annealed to make them more ductile. To anneal them, I used a propane torch, heated them to cherry red, and then quenched them in water. Quenching steel hardens it, quenching copper makes it softer. After that they bent around the jig beautifully.

Tansu bails are traditionally attached to the drawer front with a metal strip shaped like a cotter pin. The pins are pushed through holes in the drawer face, opened, laid flat, and their pointed tips are driven into the back of the drawer face, not unlike a clinch nail. Having access to solid bronze cotter pins (shoutout to Stoneway Hardware in Seattle), I decided to use those instead of making copper ones.

Cotter pins typically have a teardrop-shaped hole; I made the holes a little rounder by inserting a piece of round bar and then carefully pinching the pin around it with needle-nose pliers. I also sharpened the tips to make them easier to hammer in. Before the final installation there was a lot of dry-fitting, checking the movement of the pull, and then several small tweaks to get them to swing freely. I made all these adjustments using a dummy drawer front drilled for the cotter pins.

Cotter pins typically have a teardrop-shaped hole; I made the holes a little rounder by inserting a piece of round bar and then carefully pinching the pin around it with needle-nose pliers. I also sharpened the tips to make them easier to hammer in. Before the final installation there was a lot of dry-fitting, checking the movement of the pull, and then several small tweaks to get them to swing freely. I made all these adjustments using a dummy drawer front drilled for the cotter pins.

For the small round escutcheons, I again went to the hardware aisle and found solid copper rivet burrs. They needed to be dome shaped to work as escutcheons, so I used a dapping block and hammered them into shape.

After installing all of the pulls, I hammered a single small nail into the drawer front where the pull would contact the drawer face. This nail, called an atari, protects the wood from being dented by the pull’s dropping.

|

|

Hand bent bails. The tapered copper bars bend smoothly and easily over the jig, yet are plenty stiff enough to hold their shape. Because of copper’s softness, it’s key to make sure the jig’s surface is smooth so it doesn’t leave texture on the finished bail.

|

|

The bail gets finished and fixed. After completing the bend, Cullum polishes the bail, then adds at each end a cotter pin with a customized copper washer. He gives the washers their domed shape with a dapping block.

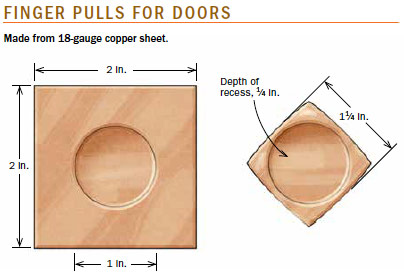

Finger pulls for the doors

Making the recessed door pulls involved a little trial and error (a specialty of mine). In my attempt to make a low-tech punch press, I started out using different sizes and types of wood dowels paired with drilled wood blocks, and I tried different hammering techniques. But the wood just couldn’t withstand the folding forces of the copper, and the process left creases in the sides of both the copper and the dowels. Then I arrived at a tooling solution that worked beautifully.

Making the recessed door pulls involved a little trial and error (a specialty of mine). In my attempt to make a low-tech punch press, I started out using different sizes and types of wood dowels paired with drilled wood blocks, and I tried different hammering techniques. But the wood just couldn’t withstand the folding forces of the copper, and the process left creases in the sides of both the copper and the dowels. Then I arrived at a tooling solution that worked beautifully.

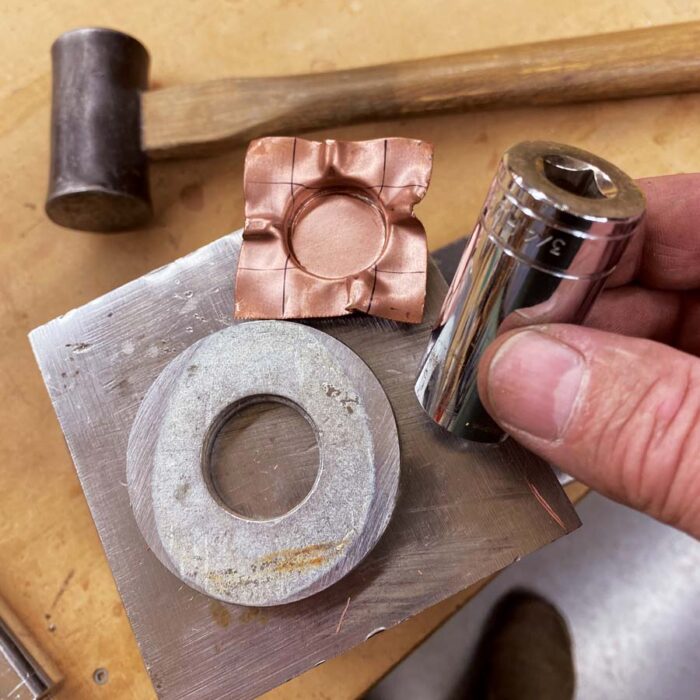

It started with annealing 2-in. squares of copper to get them soft enough to stretch while forming. Without annealing they just crumple and tear. Next I stacked two 1⁄8-in.-thick, 1-in.-dia. washers on an anvil, waxed both sides of the copper and the end of a 3⁄4-in. socket, and then gave the socket a couple of good whacks. Once the socket reached the anvil, I removed the copper, carefully tapped out the wrinkles on the upper surface, cut it to shape with snips, and sanded over the edges to give it a slightly domed appearance. Lastly, I drilled two nail holes in the walls of the recess and polished the pull with abrasive pads.

|

|

Homemade punch press. With a sacrificial socket wrench socket and a couple of big washers, Cullum devised a machine to emboss copper sheet for finger pulls. After pounding, he carefully taps out the wrinkles in the skirt around the recess.

Sweet transition. After tapping out the wrinkles, Cullum trims the skirt with snips, smooths the edges with a file and abrasives, then polishes all surfaces. He also drills two small holes for nails in the side wall of the recess.

Making this hardware was far from cost effective or efficient, but it was worth it. I got what I wanted, and I learned a lot that will inform future projects.

Len Cullum works wood in Seattle, Wash.

Log in or create an account to post a comment.

Sign up Log in