Extracting stubborn nails from reclaimed wood

A crucial step in using reclaimed wood is removing all the metal. Here's an effective way to rid your board of nails.

From early on in my woodworking career, I favored reclaimed wood over buying new lumber. While saving on cost was a consideration, my primary motivation was the desire to preserve and conserve good material rather than see it wasted.

From early on in my woodworking career, I favored reclaimed wood over buying new lumber. While saving on cost was a consideration, my primary motivation was the desire to preserve and conserve good material rather than see it wasted.

I continued this tradition when I became a woodworking teacher at our school. Our school building is located in a prime New York City location, a stone’s throw from 5th Avenue, in a neighborhood where apartments are lavishly built and expensively decorated. Often, when a new tenant acquires a preowned apartment, the entire interior is gutted to provide a clean slate for the creative aspirations of the new owners—or, more accurately, their decorators.

The material discarded during these expensive renovations has become a treasure trove of opportunity for my students and our program. From plywood to softwood to exquisite hardwoods, I consider everything that the higher echelon of Manhattan deposits into the demolition dumpsters. A few weeks ago, after crossing Central Park to the corner of 79th Street and 5th Avenue, I found a collection of impressive demolition bins awaiting the dumpster truck. While most of the bins’ contents were unsalvageable plywood, drywall, and metal studs, an exotic hardwood pallet caught my eye. The boards from one long pallet, which had the texture and color of Iroko wood, had already been pried off from the ties, so I didn’t have to deal with any disassembly effort. Had that not been the case, a long pry bar and a hammer would have helped with the job.

I also noticed that the workers who dismantled the boards bent the nails flat to mitigate handling injuries before leaving them standing upright between the bins.

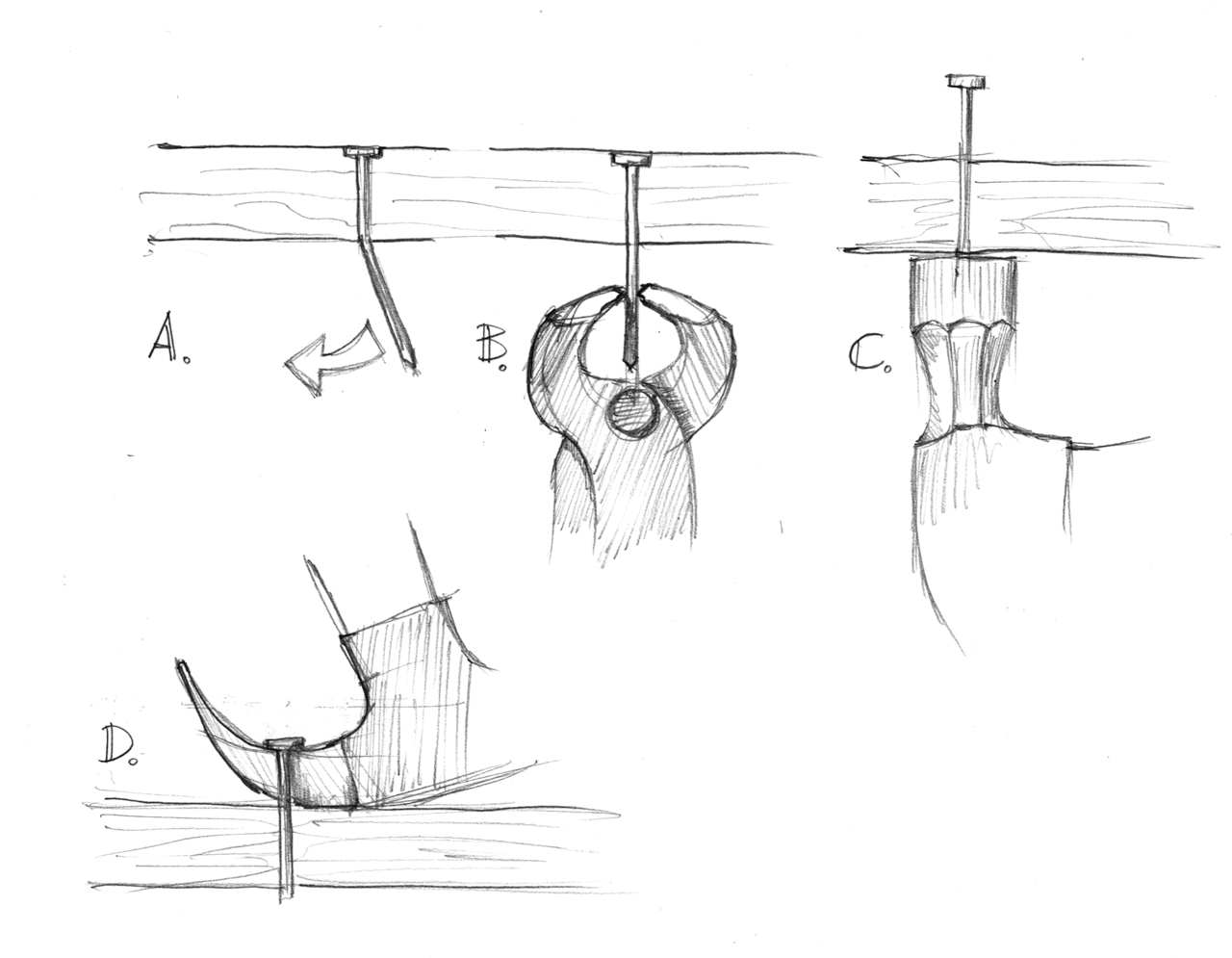

After bringing the boards to my school’s shop, the nail extraction began. While the simple way to deal with the nails is to straighten the bends, then hammer on the tip to expose the head for extraction from the other side, I took a more prudent approach. Experience taught me that hammering a long, rusty nail has a 50% failure rate. As you drive the nail to expose its head, it might bend or break. Then, when you turn the board over to pull on the head, the long retrieval travel in the hole increases the risk of stripping the nail’s head.

My solution is simple. After bending the nail straight, I snip it, leaving about ½ in. of the nail proud over the surface.

Then, I hammer the snipped portion down to expose the head, followed by a conventional extraction with a clawed hammer or nippers.

Then, I hammer the snipped portion down to expose the head, followed by a conventional extraction with a clawed hammer or nippers.

But what if it breaks off while straightening? In this case, I grab a punch or a nail set and use it to drive the nail’s tip into the wood until the head is exposed.

But what if it breaks off while straightening? In this case, I grab a punch or a nail set and use it to drive the nail’s tip into the wood until the head is exposed.

Next time, I will discuss other ways to extract hardware from reclaimed lumber, so stay tuned.

I hope this practical tip helps you in your woodworking projects, especially those involving reclaimed wood. By sharing these techniques, I aim to inspire a more sustainable approach to woodworking, making the most of materials that might otherwise go to waste.

Comments

I had a bunch of salvaged construction lumber. My approach was somewhat different. I did cut the nails extending out the bottom and hammered them flat. I used a vice grip to pull the nails out the top. Locked onto the nail right at the surface and pry.

After pulling all the visible nails I purchased a very inexpensive carbide blade from Harbor Freight for my cabinet saw and if there was a nail hidden in there I just cut the material, nails and all. The blade held up much better than I expected. It lasted just about long enough to cut up my pile.

Salvaging lumber is satisfying and rewarding for lots of reasons—most covered here. I’d suggest only one thing. If using a claw hammer to remove really stubborn nails find one with ripping claws. They are straighter than those on the hammer pictured and yield a bit more mechanical advantage when muscling out large and/or especially tight nails (and even some other fasteners and bedded metal items).

Thanks for sharing this with us. I agree that a framing hammer has excellent advantages in reclaiming jobs. The advantage of the curved/common claw hammer is that it can handle a longer nail with one swoop of the hammer. A rip claw nailing hammer will do the job, too, but it might not extract the nail in one swoop because of its limited sector rotation. To overcome this issue, I often extract the nail in two stages. I begin lifting the nail as the hammer's claws are in contact with the wood (tucked between the nail's head and the board), levering the head upward to the full extent of the sector, and then I place a spacer under the hammer head and swing the hammer again to release the nail. A pry bar is another great tool for the job. Most bars have a curved heel that allows you to swing the nail in one rotation, which is an advantage.

Log in or create an account to post a comment.

Sign up Log in