STL319: You make your own dowels?

Phil, Mike, and Ben discuss store-bought vs shop-made dowels, what wood to use for floating tenon stock, and whether CAD models negate the need for full-size mockups. |

|

Same species for loose tenons?

From Christopher:

I’m wondering if there is an advantage to using the same species of wood when doing loose tenon joinery. Eg. if the workpieces are pine, would it be better to use shop-made pine dominoes vs the white oak Festool iteration? One wouldn’t use wildly dissimilar or oily wood for a glued tenon; But as far as the usual suspects available in the building materials section, is this worth considering for the quality/longevity of the glue joint? I would love to hear your thoughts.

Groovy dowels or smooth?

From Luca:

Store-bought dowels have these grooves in them to avoid glue entrapment at the bottom of the hole – but to me, the grooves seem pretty deep. Makes me think homemade dowels without grooves would create a stronger connection. What are your thoughts on this matter?

To CAD or not to CAD?

Also from Luca:

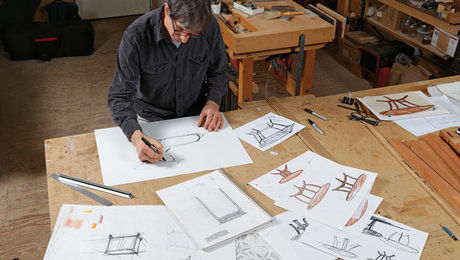

I just create designs and plans with pen and paper. I draw the project to scale but I’m never confident that this design will actually look good in real life from different angles. For my next bigger project I will definitely make a life-size mock-up. But after that, I was wondering if it was worth the effort to learn how to model a project with some kind of CAD program. In your experience, does it replace the need for mock-ups to get the proportions right? Or did you ever model something that you were very confident in and then once you built it, it just didn’t look as good?

|

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@finewoodworking.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

I have to say, even tho I took Mike's latest design class, I tend to use a similar process to Phil's when designing projects. I'm tired of trying to learn SketchUp. I'd rather go to my pad and pencil. I guess we tend to stick with what works and doesn't hold up the process.

You can get various collets for palm routers here:

https://bitsbits.com/product-category/whiteside-router-bits/accessories/router-collet/

Mostly used for CNC, but should work in any application.

Using a vice to compress tenons can cause bad results. Crushed wood fibers do not return to their original size when hydrated with glue. This could cause a loose fitting joint. It is best to sand or plane the tenons to the correct size if they are too big for the mortise.

Agreed. I usually use hardwood/plywood auxiliary jaws in the vise to prevent the metal jaws from crushing. The goal isn't to reef on the tenon stock too much.

I've also sanded and planed. The risk there is that it can be all too easy to go too small.

Phil

Log in or create an account to post a comment.

Sign up Log in