Spring-Pole Lathe Turning

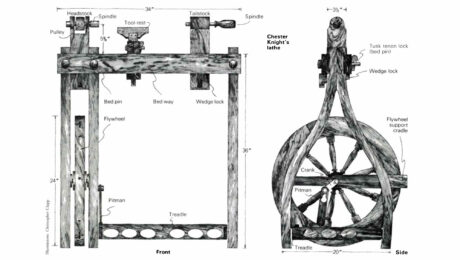

Peter Follansbee gives us a fascinating glimpse into his turning process—as though it were 1684.There’s a lot of turned work on the Essex County cupboard I demonstrate in Fine Woodworking #312. I use a pole lathe; the action is provided by a foot-treadle below and a 12-ft.-long sapling in the ceiling above. A cord tied to the sapling wraps around the workpiece and runs down to the treadle. Each kick of the treadle spins the turning toward the tool, then the pole springs it backward. Then comes another kick. I often reserve a short section on the turning as the place the cord wraps around.

On the pole lathe there’s no drive center; the work spins on two iron points. If you were to glue up your blank the way most modern turners do, fixing it between the lathe’s points could split it along the glueline. To get around this, I glue up a pair of maple blanks with a 3/16-in.-thick center strip between them. The lathe’s points engage the sacrificial center strip. It’s a job for hide glue because you need to be able to take the pieces apart once they’ve been turned. When the turning is done, I steam it over a pot of boiling water to soften the hide glue. Once it’s loose, you can slide a putty knife in there to separate the turnings from the center strip. It’s like magic.

Copy and photos are from Peter’s article “Essex County Cupboard” in Fine Woodworking #312.

Log in or create an account to post a comment.

Sign up Log in