STL325: From Logs to Lumber

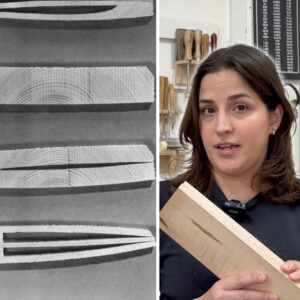

Amanda is joined by Brenon Plourde and Logan Wittmer to discuss milling logs, drying lumber, and their mutual "problem" of hoarding the perfect board.

Chuck:

Lets say someone says “I have this oak log I can mill up for you into boards”. You don’t have any plans for what to do with the material other than build something when it air dries in a year or two. How thick would you ask for the boards to be milled? (Based on a true story)

And I should mention, I can re-saw the boards and do the jointing/planing once they’re dried.

What are the important ‘avoid doing this or do this when air drying’ tips these guys have to offer?

Amanda:

Favorite species to mill and or dry and why.

What were either of your first bandsaw mills (portable or not) and what size do you recommend as a good starting point? Any other big costs that need to be factored in?

|

Milling Your Own LumberWhether a hobby or a small business, it’s a woodworker’s dream job. |

Logan- do you exclusively air dry your material or does any go through a kiln cycle? If so, what makes you decide to do so?

Brenon- does most or all of your material go through your solar kiln? Can you mix species pretty easily with similar drying times?

What is the time window for drying in summer vs winter?

Do either of you ever outsource drying your material when you have excess?

How much of your logs come from your own property, and when you do get logs from other properties, what is your ideal source?

Brenon – you mentioned a wax you use for sealing the end of logs when they’re cut, can you explain what that is and why you prefer it?

Do you have a preference on sticker material or do you just use whatever material you have?

How do you go about examining each log to get the best/most usable material?

Editor Recommended End-Grain Sealer

AnchorSeal Log and Lumber End-Grain Sealer

Log in or create an account to post a comment.

Sign up Log in