Video: The Digital Sawhorse Experiment

An experiment to see how many sawhorses can be pulled out of a single sheet of plywood goes wrong.The initial plan seemed simple: design and cut sawhorses using a single 4×8 sheet of plywood. The catch? Our CNC only handles 2×4 sheets, forcing me to rethink how to optimize cuts and designs within those constraints. As I began designing in CAD, it became clear that this project would evolve into more than just sawhorses—it would become a hybrid of practicality and experimentation. After some back and forth in Fusion 360 and a few head-scratching moments, I ended up with two distinct creations.

The Tall Miter Saw Stand-Sawhorse Hybrid

Designed with rigidity in mind, this stand functions more as a temporary workstation for miter saws or similar tools. While it wasn’t exactly what I set out to make, it proved surprisingly sturdy and versatile. Sure, the notches were looser than I’d planned, but a few strategically placed wedges saved the day.

The Short Stackable Sawhorses

These compact sawhorses turned out to be my favorite part of the project. At 16 in. tall, they’re perfect for propping up materials, acting as a bench-on-bench, or even just keeping things off the floor. Designed to nest for easy storage, they’re incredibly handy in the shop despite a few overlooked details, like missing notches for stacking.

Check out the sawhorse that inspired one of these designs:

|

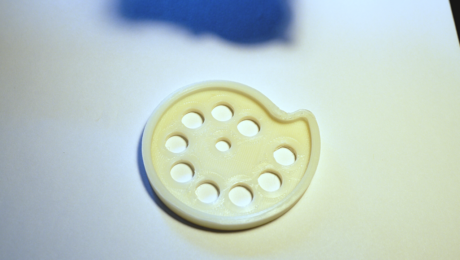

Woodsmith’s Stacking SawhorsesA simple system of interlocking tabs and notches makes this set of stacking sawhorses as sturdy as they are versatile. |

Lessons Learned

This project was a reminder that woodworking—and especially CNC woodworking—doesn’t always go as planned. From misaligned dimensions to unexpected CNC issues (hello, drag-chain disaster!), it was one challenge after another. But that’s the beauty of making: each project teaches you something new.

Comments

What was the "dare" here? To make sawhorses on a CNC? Or to find out how many saw horses you can make from a single sheet of plywood?

If the latter then you could simply scale the project to 25% of normal and lay the 2' x 4' sheet out as if it were a 4' x 8'. In this case I would source some 3/16" birch plywood (yeah I found that on line). So the fit-up is more realistic. After the concept is proven by modeling, buy some 3/4 x 4' x 8' sheeting and fire up your hand held jigsaw for the FW-Shop.

Realistically, who is going to use a CNC to make sawhorses? And who dared you to do this, Ben? Maybe we should have a talk with your parents about accepting dares in the playground ... er, wood shop.

Log in or create an account to post a comment.

Sign up Log in