How to Handle Plywood

Take the backache out of sheet goods and make better cuts, too

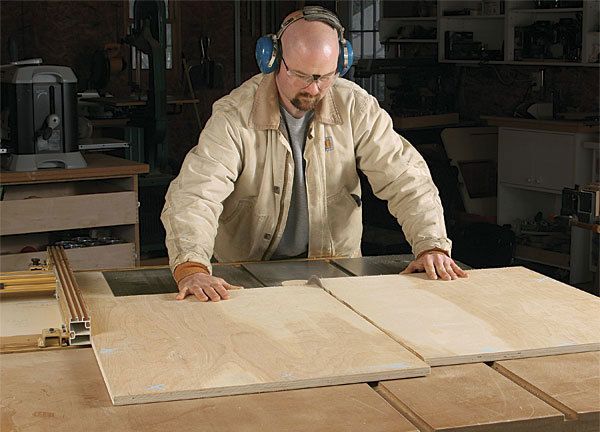

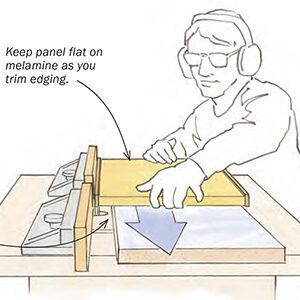

Synopsis: Learn the best way to handle sheet goods such as plywood, melamine, and MDF without hurting yourself or damaging the wood. Gregory Paolini takes you to the lumberyard, where the process begins, and walks through buying sheet goods, getting them home, keeping them flat, cutting them into manageable sizes, and making final rip- and crosscuts without tearout.

From Fine Woodworking #208

Plywood, melamine, and other sheet goods are great for cabinets, shelves, racks, and more. These materials are large, flat, and stable, but they’re also heavy, awkward to handle, and hard to transport. Being a solo woodworker, I’ve learned lots of tricks for buying and handling sheet goods safely and efficiently. It all starts at the lumberyard.

How to get the sheets to the shop: If you’re buying hardwood-veneer plywood, it’s worth paying a delivery charge to have the supplier bring those expensive sheets right to your shop door; there’s less risk of having the veneer damaged in transit. Save your energy for transporting less expensive plywood and medium-density fiberboard from the local home center.

Before you go to the lumberyard, make a cutting diagram for each sheet. It’s the best way to get the most out of each sheet, so you won’t buy more material than you need. The diagram also shows you how to cut down the sheets to a more manageable size before you bring them into the shop. Rough-cutting the sheets is especially important if you don’t have a pickup truck or a van.

Most home centers and lumber retailers have a panel saw and will generally make one or two cuts for free or for a nominal fee. Before you have the sheet cut to rough size, mark the factory edges for later reference if they don’t already have a mark from the mill.

If it’s not possible to cut down the sheets at the home center, you’ll need a truck to carry full sheets home.

The bed on a full-size pickup is wide enough to hold 4×8 sheets flat between the wheel wells; with a short-bed pickup, you’ll have to fold down the tailgate. Compact pickups can’t fit a 4×8 sheet between the wheel wells, but many have indentations in the bed sides for 2x lumber that will support a load above the wells. If you don’t have a way to keep the sheets flat, slide them over the closed tailgate and tip them down so the edge butts against the front of the bed. Don’t overload the tailgate. A tiedown near the tailgate secures the load. Use cardboard or a blanket to protect the sheets where they contact the truck. Flag any load that extends past the truck bed.

Handling sheets at the shop: If you rough-cut the sheets to size at the home center, getting them into your shop is simple. If not, you have a bit of work to do. With a larger truck, you can rough-cut the sheets with a circular saw as you slide them out of the truck, using the tailgate as a makeshift sawhorse.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

DeWalt 735X Planer

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in