A Revolution in Chair Making

When you separate the seat and back from the structure, the chair making process gets easier.

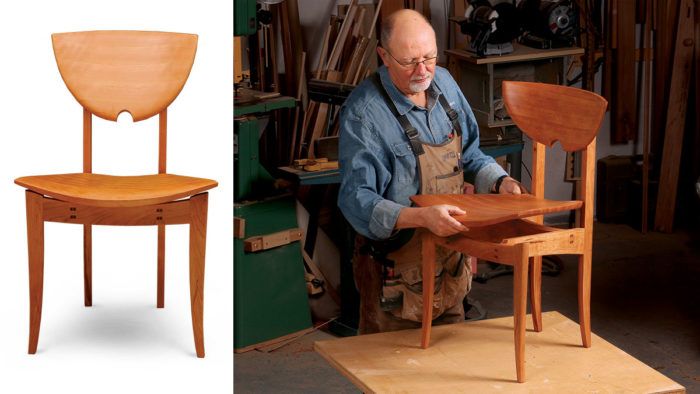

Synopsis: Beauty, comfort, and strength come together in this chair designed by Michael Fortune. In traditional chairmaking the legs, rails, seat, and back are part of a single unit. This design throws all that out the window. By separating the seat and back from the legs and rails, you can build the base first. Because the legs and rails are square to one another, the joinery is much simpler. The seat and back are attached to the base with screws after they’ve been shaped for comfort. Handy jigs take care of the multiple mortises in this chair, and make it easy to create an identical set to fit around a dining table.

I have designed dozens of chairs during my career, and made several hundred. Whenever I design one, I strive to make it beautiful, comfortable, and strong. Meeting those goals often means the chairs are difficult to build, with parts meeting at compound angles. And then all those parts must be hand-shaped so they join seamlessly.

So, I began looking for a less complex way to make chairs, while remaining true to my design goals of beauty, comfort, and strength. In traditional chairmaking the legs, rails, seat, and back are part of a single unit, which complicates construction quickly. With this design, I borrowed from techniques developed in Scandinavia during the mid-20th century. By separating the seat and back from the legs and rails, you build the chair’s base first and then add the seat and back to it. As a result, the legs and rails can be square to one another, which simplifies the joinery. But the seat and back can be highly contoured for comfort, and then attached to the base with screws (I have a great technique for the shaping).

A chair like this is for a dining table, so you’ll be planning to make at least four, but more likely six or eight. since you’re basically taking your woodworking into production mode, I’ll show you some nifty jigs that will make the process go more smoothly and quickly.

I’ve now made a lot chairs this way, and I couldn’t be happier with the results. The basic structure and technique is flexible enough to accommodate a variety of designs. Best of all, even a novice chairmaker can use the technique and make great chairs right away.

One jig handles many mortises

The curved legs give the chair an air of complexity. But that’s an illusion. The rails and legs meet at right angles and slip tenons hold them together, except for an integral tenon where the side rail joins the back leg. Making the joinery comes down to routing a bunch of straight mortises. The slip tenons are basically straight sticks planed to fit. As for the curves in the legs, don’t sweat them. use the drawings to get you close and trust your eyes when making templates.

From Fine Woodworking #227

Online Extra: SIM: Bandsaw Jig for Curved Parts

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in