A Bench Built to Last

This workbench has a wide top and a sturdy base that provides solid footing and plenty of storage space

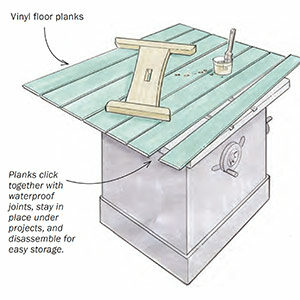

Synopsis: This massive workbench owes its sturdiness to its modular base. Its top is flat and durable, it supports a variety of vises, and its wide edgings accept benchdogs. Board jacks support long stock, and the space under the bench has ample storage. The author added power strips to his bench, since it’s several feet from a wall. Detailed project plans give dimensions and clarify the joinery.

If this workbench played football, I’m certain it would be a lineman. Because, like the guards and tackles found on the gridiron, my bench is big and solid. And I wouldn’t have it any other way.

Most of my work involves the fabrication of large case goods— entertainment centers, bookcases and other types of storage furniture. And although much of the machine work gets done using a tablesaw and router, I still do a good deal of work at the bench. So when it was time to replace my older, smallish and somewhat rickety workbench, I opted to make a new one with all the bells and whistles. The bench would provide plenty of size and sturdiness. Sturdiness is the operative word here. Indeed, no matter how aggressive I get with a saw, a handplane or a mallet and chisel, the bench doesn’t wobble. The result is a workbench that has just about everything I need.

The supersized top is another important feature. With about 22 sq. ft. of surface area, the top is great for supporting long boards and wide sheet goods. Two end vises, a front vise and a shoulder vise, along with a small army of benchdog holes, make it easy to secure almost any size stock to the bench.

My bench is considered left-handed, based on the location of the shoulder vise. If you prefer a right-handed bench, just build the shoulder vise on the right side.

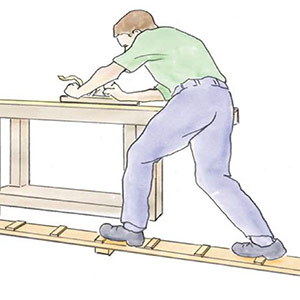

The base creates a sturdy foundation

The bench owes much of its sturdiness to the design of the base. Yet its construction is pretty straightforward. It has just five main parts: three support frames and a pair of boxes. Screwing the frames and boxes together creates a single, rock-solid unit that can accept almost any kind of top. And the two boxes provide a ton of space for adding cabinets or drawers.

The center and right-side support frames are identical. But to provide additional support for the shoulder vise, the left-side support frame is longer and has an extra leg. I added seven heavyduty levelers—one under each leg of the support frame.

To simplify the construction of the base, I made both plywood boxes the same size. They fit snugly between the top rail and the foot of the frames, which adds rigidity to the base.

If you include drawers in one of the boxes, as I did, cut the dadoes for the drawer-support cleats, then glue the cleats into the dadoes before the box is assembled.

From Fine Woodworking #149

For the full article, download the PDF below:

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Drafting Tools

Compass

Log in or create an account to post a comment.

Sign up Log in