The Essential Workbench

Workhorse bench combines the best of the old and the new

Synopsis: The author and Fine Woodworking editors collaborated to design an essential workbench for today’s woodworker, one that is straightforward to build and is more of a workhorse than showpiece. Its also a bench that most woodworkers can build using tools found in an average small shop: tablesaw, portable planer, crosscut saw, router, drill press, and hand tools. Details such as round and square benchdogs are debated and resolved, and though this design doesn’t have a tool tray, one could easily be added.

This latest attempt to design a woodworker’s bench is built on the foundation of the dozens that have graced the pages of this publication, starting with Tage Frid’s in the fall of 1976 (FWW #4). His includes a built-in tool tray, a shoulder vise on the left, and a tail vise on the right, with a single row of dog holes along the front apron—much different from the bench seen here. Frid’s bench is a classic northern-European design that traces its roots back centuries before the introduction of electricity. Frid’s bench and Frank Klausz’s very similar design a few years later (FWW #53) have influenced modern bench builders for decades.

Several Fine Woodworking editors and I recently collaborated on designing an essential workbench for today’s woodworker, one that is straightforward to build without compromising performance. This bench was designed to be a tool—more workhorse than showpiece. We did not include traditional components simply for history’s sake, and we took advantage of modern innovations. We also wanted this bench to be a project that most woodworkers could build using tools found in an average small shop: tablesaw, portable planer, crosscut saw, router, drill press, and hand tools. The only heavy-duty tool I used was a 3-hp tablesaw. Ripping lots of 8/4 maple puts a strain on even a large saw, so use a clean, sharp blade.

Avid woodworkers themselves, FWW editors regularly visit shops across the country, and they see a wide array of workbench configurations. Like all woodworkers, they know what they like and don’t like. In the end we all compromised a bit, but we reached a solid consensus. My own involvement arose from having spent the last year researching and writing a book on workbenches. I was commissioned to finalize this design, write the article, and build the bench.

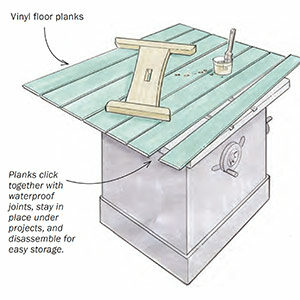

We decided on an overall size of 28 in. wide by 6 ft. long. Add a few inches for vise jaws, and it’s a nice, big top. The editors thought 2 in. in top thickness would be plenty, with extra thickness at the edges, but I made this top 2-1⁄2 in. thick because it wasn’t much more difficult to mill and laminate thicker pieces. However, if you start with a premade bench slab, the standard 1-3⁄4-in. thickness offers plenty of mass and solidity for serious hand-tool use, especially after adding the thicker apron and end caps.

Gluing up the slab allowed me to machine the square dog holes before the pieces were assembled. Round dog holes might be a better option for a premade slab because square ones are best cut while the top slab is in pieces.

From Fine Woodworking #167

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Woodriver Rechargeable Desiccant Bag

Compass

Sketchup Class

Comments

None of the plans on the fine woodworking site are available

I don't see a plan for that workbench in the Taunton Store, either. There are plans for other workbenches, however. It looks like there's enough information in the article to build this one, though.

Log in or create an account to post a comment.

Sign up Log in