Synopsis: Norman Vandal can’t get along without his set of old molding planes. But when he needed a plane he didn’t have, he made one. Here, he explains how in a way that also helps you get an old plane back in usable condition. First, figure out the molding profile, which will determine the width of the iron. Next, shape the sole of the plane to the reverse profile of the molding, and then true the iron to the sole and get started. He details molding shapes, plane designs, stock options, irons, layout, shaping, and setup. He talks about sawing out the mouth, mortising the wedge slot, making the wedge, shaping the irons, tempering, finishing the wedge, and setting the iron. Side information covers boxing the sole, or adding Turkish boxwood into the sole to reinforce it.

You still can spot old molding planes in antique shops or junk shops, but they aren’t as common as they used to be. Prices can be as low as $8 to $15, so people snap them up to use as decorations. I can see displaying these old tools because they are aesthetically pleasing, but it’s really a shame not to fix them up and use them. They were fine tools once and can work just as well again.

I make a lot of period furniture, and I can’t get along without my set of old planes. When I needed a reverse ogee molding with cove for a cornice on a cabinet, I decided to make a plane to do the job, designed around an old iron I’d found that had become separated from its original block.

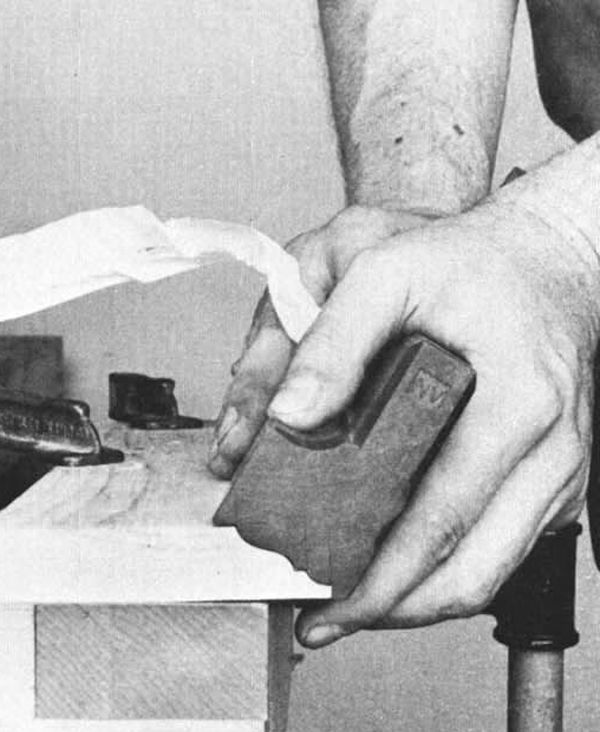

I’ll describe how to make such a plane from scratch, so that if you come across an old molding plane or iron you will be able to get it working again, regardless of its condition. Whether you are starting with an old plane block or an old iron, or from scratch, this is the general scheme: First you must know the molding profile, which will determine the width of the iron. Next you must shape the sole of the plane to the reverse profile of the molding. Then you can true the iron to the sole and start making molding.

If you come across a plane with a poorly shaped iron, don’t change the shape of the sole to conform. The contour of the sole represents the molding the plane was designed to make. A poorly matched iron is usually the result of inept sharpening or grinding. Recondition a damaged iron by annealing it (softening it by heating), filing it to fit the sole and then retempering it.

The style of plane I’ve chosen is based on the finer 18th-century examples, and all the standard dimensions discussed are characteristic of this period. You may, of course, alter the design, but this pattern is a good starting point.

From Fine Woodworking #37

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Estwing Dead-Blow Mallet

Log in or create an account to post a comment.

Sign up Log in