Synopsis: William Corneil says a bandsaw can do everything a tablesaw can do, and it can cut curves. So he made his own. Here, he explains why and how he did so. His saw can even go slowly enough to cut iron. The project involves some basic metalworking skills, and he recommends improvements over his own model, such as using roller or needle bearings instead of bushings for the wheels. He breaks the construction down into three components: the base, the saw body, and the mechanicals. His base is plywood screwed to four 4×4 legs. This detailed article describes every step of building a bandsaw.

Most woodworkers’ thoughts turn to tablesaws and radialarm saws when they’re confronted with buying a large stationary saw. But I’m different in two regards. First, I chose a bandsaw, for reasons that I’ll make clear in a moment. And, secondly, I opted to build the machine myself rather than buy it.

I chose a bandsaw because it can do many things a tablesaw can do, plus it can cut curves. As a project, it seemed less daunting than building a tablesaw or radial-arm saw, both of which would be great to own but are too expensive to buy on my budget.

My problem as an amateur woodworker is that I find it hard to justify (to myself and my spouse) the need to buy larger stationary equipment simply to “build better birdhouses.” Granted, many cutting tasks are performed quicker on a tablesaw, but for the amateur, time doesn’t mean money. Aside from cutting curves, I can resaw, rip and even cut lumber from logs on my saw. It also has five blade speeds: 120, 300, 600, 1,200.and 3,000 feet per minute (fpm). The slowest speed allows me to cut -in. angle iron.

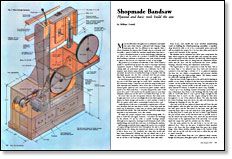

As machinery goes, the price was right. I built the 20-in. saw you see at left three years ago for under $100, Canadian (about $72 American today). I kept the cost down by using locally available materials and hardware. Most of the saw is built from -in. interior-grade plywood and construction-grade lumber (which needs to be dried well first). I recently swapped the saw’s -HP motor for a used -HP model, but the smaller motor is more than adequate, unless you use the saw to cut lumber from logs, as I do.

It’s ironic that my saw incorporates features that many storebought saws don’t, such as a worklight above the blade guard, one drawer for blade storage and another to catch sawdust, a built-in ll0v AC power outlet and a conveniently located power cord.

Anybody who’s built even a reasonably complex piece of furniture shouldn’t find the saw hard to build. I built mine with the usual cast of characters: a saber saw, an electric hand drill and a borrowed belt sander. The only machine I used that many shops may lack is my homemade 12-in. disc sander.

I’ll admit the project requires basic metalworking skills. If I were to build the saw again, however, I wouldn’t use bushings for the wheels; I’d opt for roller or needle bearings instead.

From Fine Woodworking #65

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Precision Square

Shop Fox W1826

Log in or create an account to post a comment.

Sign up Log in