Synopsis: If you’ve attempted to dovetail cupped boards or build a frame-and-panel door from bowed lumber, you know how frustrating it is to work with poorly prepared stock. Peter Korn explains six steps to creating foursquare stock: flatten the first face, make the second face parallel, square an edge, rip the second edge square, cut an end square, and cut the other end square and to length. He details each step and adds side information on flattening the face of a board with a handplane.

If wood were a stable, homogenous, man-made material like metal or plastic, how much simpler the woodworker’s task would be! Instead, we pay a price for our love of natural beauty. We work with a biological medium that reacts continuously to the environment, changing dimension and shape as it breathes moisture in and out.

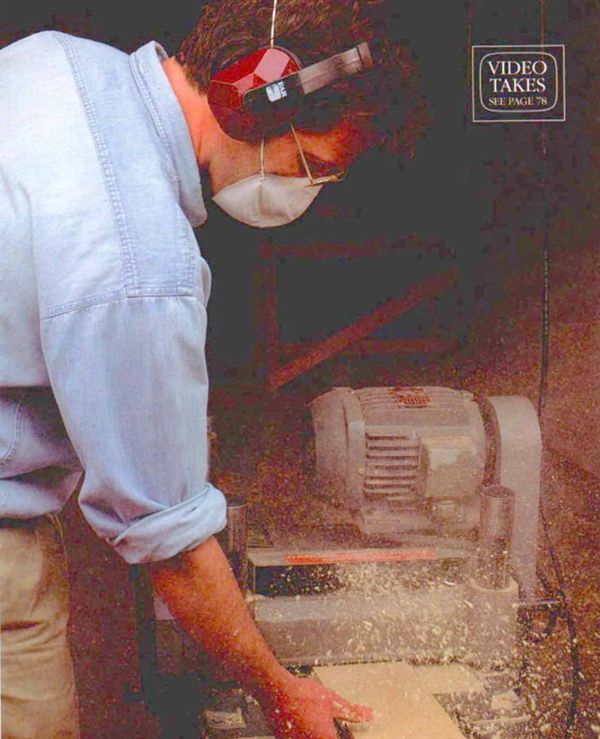

If you’ve ever attempted to dovetail cupped boards or to build a frame-and-panel door from bowed lumber, you know how frustrating it is to work with poorly prepared stock. Fine craftsmanship occurs one step at a time, and the first step is preparing (milling) stock foursquare—straight, true and accurately dimensioned.

Boards are almost never flat enough to use directly from the lumberyard. Even S2S (surfaced two sides) lumber is milled only with thickness planers, which create boards of uniform thickness but do little to iron out cup, bow or twist. In any case, wood’s propensity for continuous movement dictates milling only when you’re ready to use it. Stored wood will often warp between milling and joinery.

I begin every project with a cutting list specifying the exact measurements of all the parts, including allowances for tenon length. If there are curved parts, I usually mill foursquare blanks and then bandsaw the curves later. Before cutting, I lay out the location of each part on the rough lumber with chalk or a crayon, trying to minimize waste and make the most attractive use of grain. Laying out the. parts right on the milled stock also prevents embarrassing mistakes.

When the cutting list calls for several parts of the same dimension, you must weigh time against conservation of material. It takes less time to mill long pieces to thickness and then cut shorter parts from those long boards than it does to crosscut smaller pieces and then mill them.

From Fine Woodworking #102

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Estwing Dead-Blow Mallet

AnchorSeal Log and Lumber End-Grain Sealer

Log in or create an account to post a comment.

Sign up Log in