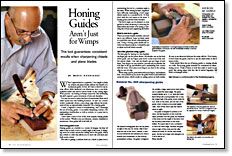

Honing Guides Aren’t Just for Wimps

This tool guarantees consistent results when sharpening chisels and plane blades

Synopsis: Developing honing skills requires a great investment of time and discipline unless you use a honing guide. In this article, Mario Rodriguez assesses four popular honing guides. He explains how honing guides work and what to look for in a guide, and then he offers tips on using them, such as using a firm grip. The models he examines are the General No. 809 sharpening guide, the Stanley No. 14-050 guide, the Veritas honing guide, and a side-clamp or vise-style honing guide.

When I apprenticed as a carpenter, I was taught to hone my chisels and plane blades without the benefit of a mechanical guide. At first, all I had to show for my intense efforts while hunkered over whetstones were a sore wrist, hollowed stones and uneven convex bevels on my cutting edges. With practice, my honing technique improved. But developing this skill required a great investment of time and discipline.

You may not want to make that kind of commitment when you’d rather spend your time building furniture. So how can a woodworker consistently obtain a razor-sharp edge without the investment of time an apprenticeship demands? Use a honing guide.

I teach a beginner’s course in woodworking, and I encourage the use of honing guides. A successful sharpening routine—for intermediate woodworkers as well as novices—is a great way to build confidence.

I have taken a look at four of the most popular honing guides on the market. Whether you use Arkansas, ceramic, diamond or waterstones, these guides will work with all.

How honing guides work

Honing guides are available in a variety of designs, but they all make it easy to hold a tool at a steady angle to the stone. A clamping screw (or screws) secures the cutting tool to the guide, which has a wheel or roller that allows you to move the tool back and forth across a stone.

The trick to getting a uniform bevel on a chisel or plane iron is maintaining the tool at a consistent angle to the stone. When honing by hand, beginners have difficulty maintaining a tool’s angle, which results in a rounded bevel. Or they don’t hold the tool square to the stone. A honing guide prevents these mistakes.

The bevel angle can be adjusted on most guides by either advancing or retracting the blade within the holder or by raising or lowering the vertical post supporting the holder.

From Fine Woodworking #132

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Micro-Adjust Wheel Marking Gauge

Lie-Nielsen No. 102 Low Angle Block Plane

Log in or create an account to post a comment.

Sign up Log in