Making Tabletops Without Coming Unglued

How the pros stay sane when gluing up tabletops and large panels

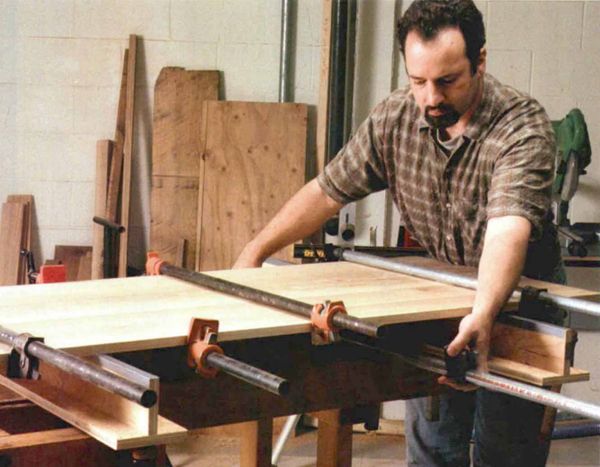

Synopsis: Getting a nice flat tabletop with tight joints isn’t a snap. Anatole Burkin interviews several woodworkers on their experiences and strategies for gluing up large panels. Gary Rogowski, Bob Van Dyke, Garrett Hack, Roland Johnson, and David Fay talk about whether to edge-glue panels to avoid cupping, or whether to pay more attention to figure and color. Some prefer biscuits; others, splines, or nothing. And they all say any large surface works fine for glue-ups. The article includes a side discussion of clamps – what kinds they prefer, how they use them, and how a Swiss glue press, parallel-jaw bar, and the scissors-style screw clamp measure up.

Building a tabletop was once as simple as finding an oldgrowth plank wide enough to serve six. Boards much wider than 12 in. are uncommon these days, and if you do find them at the lumberyard, they often go for a premium price. When a project calls for wide panels, the solution is to glue up several narrower boards to get the width needed.

Making tabletops or large panels seems simple enough: Plane and joint three or four boards, and edge-glue them. But getting a nice flat tabletop with tight joints isn’t a snap. You must mill your lumber flat and square. You need a way of registering the boards to keep them in the same plane during glue-up. And you need clamps that will hold them firmly without cupping.

Even if you think you have all that worked out, bad things happen, says Portland, Ore., furniture maker Gary Rogowski. “You can line up your stock and forget to pay attention to the ends of the boards, leaving them offset. Your extra-long boards that you’ve just glued up into a single panel are now too short in one section.”

We all suffer occasional slipups, but success in woodworking is not accidental. I asked a half-dozen woodworkers to share their experiences and strategies for gluing up large panels.

Heart side up or down?

The first step in building up a tabletop involves selecting and matching lumber. Much has been written about edge-gluing panels and how to avoid cupping. Common wisdom says you should flip-flop adjoining boards so their growth rings alternate up and down. Wood usually cups toward the bark side. Theoretically, flipflop minimizes the amount of cup across the width of a panel. If one board cups up, the adjoining one will cup down, creating a slight ripple, not one huge cup. (When using quartersawn material, which is more stable, the risk of cupping is greatly diminished.)

To be safe, you can do what most large furniture companies do: Rip everything into 2-in.- and 3-in.-wide planks, flip-flop them and to heck with nicely matched color, figure and grain. Furniture factories mask these problems using dyes and toners.

Custom furniture makers don’t rely so much on chemicals to hide badly matched lumber. Most would agree with Garrett Hack, a furniture maker in The ford Center, Vt., who stresses the importance of making a good match. “I rarely orient boards based on the direction of the growth rings. I’m more interested in consistency of figure and color.

From Fine Woodworking #132

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Trusty-Cook Dead-Blow Hammers

Glue Bottle

Bessey K-Body Parallel-Jaw Clamp

Log in or create an account to post a comment.

Sign up Log in