Seven Joinery Fixes

Don't scrap a valuable workpiece; make an invisible repair

Synopsis: In the midst of dry-fitting the side table you’ve been working on all week, you realize you got a little too aggressive and trimmed an apron tenon narrower on one end than the other. Or maybe you slipped when cutting dovetails for a drawer and broke off one of the pins. No matter how skilled the woodworker, everyone makes joinery mistakes. The secret, according to Phil Lowe, lies in knowing how to fix those mistakes.

In this article, Lowe shows you how to: shim a miscut tenon cheek; trim a damaged tenon shoulder; replace a broken tenon; fill gaps in dovetails; replace a broken dovetail pin; patch and recut a dado; and repair a chipped corner.

The work of cutting accurate joinery involves two basic, and contradictory, truths.

The first truth is that to hone your craft, you must learn and practice the correct skills, keep your tools sharp, and focus on your work. In short, avoid mistakes.

The second truth is that you cannot avoid mistakes.

Let’s face it: No matter how skilled we become, we still slip with a chisel now and then or get too aggressive with the tablesaw. Occasionally, despite our best efforts, a router bit chips away a corner.

Sometimes it’s simple enough to grab a fresh piece from the lumber rack and start again. but if you’re working with a limited supply of lumber, don’t want to discard a grain-matched board, or already have invested hours in shaping or carving a part, a joinery mistake poses a serious dilemma.

Fortunately, you almost always can save the part you’re working on. Here are some ways to fix mistakes when cutting tenons, dovetails, and dadoes.

Shim a miscut tenon cheek

The critical parts of a tenon are the cheeks and shoulders, and each can be miscut in several ways. Let’s start with the cheeks. Planing a tenon too thin is probably the most common mistake, but you also can create tenons that are twisted or trimmed narrower at one end than the other. The strategy for repairing any of these problems is to glue a slightly oversize shim to the offending side of the tenon and plane away the excess wood until the tenon is square and fits the mortise.

Make sure that the surface to be corrected is flat so that the added piece will have an adequate glue joint. For shim stock, I typically use a thin cutoff of the workpiece material. The grain of the shim should run in the same direction as the tenon so that it will shrink and swell in the same way.

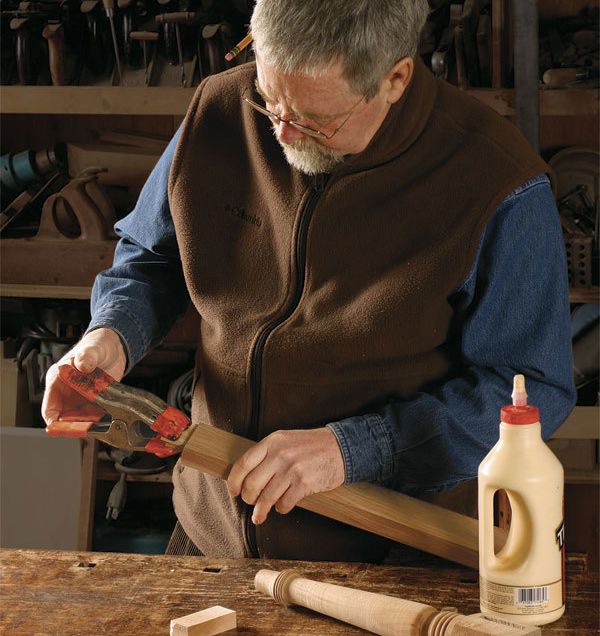

When gluing, I use a thick block as a caul to distribute the clamping pressure evenly. If the shim is very thin, glue can seep through so I use a sheet of waxed paper to prevent the caul from sticking to the work.

Although I want to do the repair work carefully, I don’t want to lose too much time in the process, so I typically use the quickest-setting glue that will hold the repair.

From Fine Woodworking #186

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Jorgensen 6 inch Bar Clamp Set, 4 Pack

Festool DF 500 Q-Set Domino Joiner

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in