Protecting Surfaces in the Shop

Machines, jigs, and benches all benefit from being sealed and waxed.

Synopsis: There’s no need to French polish your crosscut sled, but there are treatments that will make your jigs, benches, and machine tops work better and last longer. Basic finishes, such as shellac or paste wax, help keep accurate jigs from needing to be replaced, saving time and money. See how to keep your shop working at its most efficient.

We go to great lengths to protect the projects that leave our workshops from the rigors of everyday use, yet we often neglect our jigs, fixtures, shop cabinets, workbenches, and tools—the very objects that allow us to create fine furniture in the first place. There’s no need to French polish your crosscut sled, but there are treatments that will make your jigs, benches, and machine tops work better and last longer.

Prevent rust on machine surfaces

Bare metal will rust if not protected or used constantly. There are myriad products that purport to be the last word on metal protection. Each product claims to prevent rust and to leave a slick surface that will not contaminate wood. The ones I’ve tried have done neither, and I’m leery of applying oil to my saw top or jointer bed. As a consequence, I’ve adopted my own system for cleaning and protecting metal that works and doesn’t require much effort.

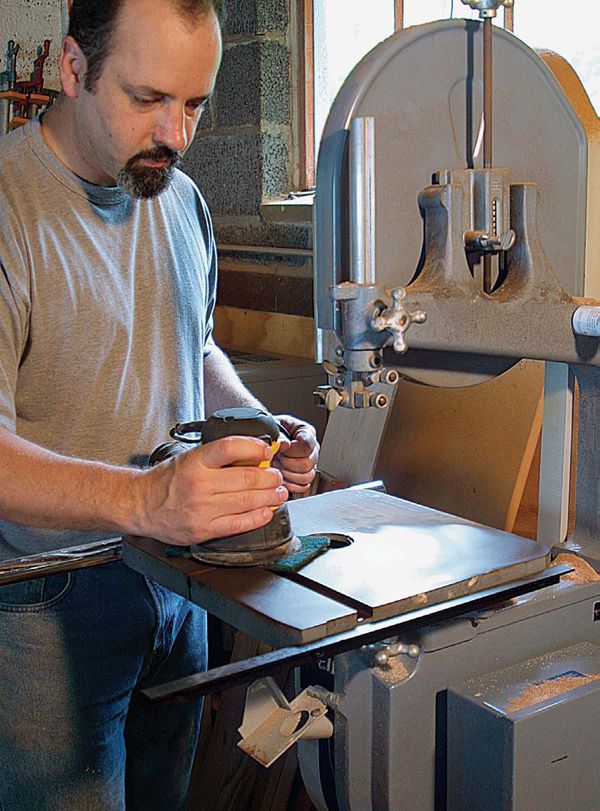

I remove the rust by buffing the surface with a green pot-scrubbing pad. Small items such as planes, chisels, or scrapers are buffed by hand, but large surfaces like my tablesaw or jointer get power-buffed with a 5-in. random-orbit sander. The hook-and-loop sanding pad holds the scrubber firmly while I guide it around the metal surface. Once it’s rust-free, I polish the surface with a wadded-up piece of waxed paper. Just enough wax (carnauba, I’ve been told) transfers to the metal surface to protect it from rusting and to lubricate it simultaneously. Boards glide across the saw or the jointer as if they are floating on air.

High-pressure laminate requires virtually no maintenance and is the ideal surface for router tables, shop-cabinet tops, chopsaw extensions, and the like. Dried glue and finish easily scrape off, and a quick rubdown with waxed paper keeps the laminate slick.

Wax for machine surfaces

Wax treatment. You can use kitchen waxed paper to protect and lubricate a machine bed. Crumpling up the paper and rubbing it over the surface lays on a thin layer of wax.

Finishes help jigs last longer

It may seem unnecessary to finish jigs, but there are several good reasons to put in the effort. Even simple jigs help us hold, saw, or bore wood precisely. The usefulness of most jigs depends on their accuracy, and they require a fair amount of time and effort to construct, so it makes sense to protect them properly. The type of finish depends on how the jig is used and the material it is made from.

Shellac on solid wood—Finishing jigs with shellac virtually eliminates dimensional changes in solid wood caused by seasonal humidity. Shellac has the lowest moisture-vapor transmission rate of any finish on the market today. That means the moisture content of wood finished with a few coats of shellac will barely change, even if the level of humidity in the shop varies significantly.

I prefer dewaxed shellac to finish furniture, but for jigs I use the hardware-store variety of premixed orange shellac. That cloudy stuff in the can is natural shellac wax, which lubricates the sliding surfaces of the jig and allows it to glide across a tablesaw easily.

Paste wax for plywood—Plywood and tempered hardboard remain dimensionally stable over wide humidity swings, so they are ideal materials for your most critical jigs. Often a coat of furniture paste wax is all the protection needed for jigs made from these stable materials. The paste wax also helps the jig slide more easily during use.

Glue size seals MDF—Medium-density fiberboard (MDF) is less seasonally stable than other manmade sheet goods, but it still can be used for jig construction if properly sealed. The edges of an MDF sheet are considerably more absorbent than the faces. If left unfinished, the unprotected edges can absorb moisture and significantly swell the MDF sheet. A coat or two of finish will not seal the edges adequately, so instead I use glue size—a 50-50 mixture of polyvinyl-acetate (PVA) glue and water. Allow the glue size to dry completely, lightly sand the rough surface, then finish the whole jig with shellac or lacquer. This will provide an effective moisture barrier.

Hold the varnish—For finishing jigs, I prefer shellac or cabinet-grade nitrocellulose lacquer, which dry much faster than oil-based varnish and are available in convenient aerosol cans. More important, shellac and lacquer form harder surface films than varnish, which means that jigs coated with these finishes slide more easily over a tablesaw or router table than their varnish-coated cousins.

Finishes for jigs

Benchtops need protection, too

When it comes to finishing a workbench, I find that woodworkers fall into two camps: Some lavish as much attention on finishing their bench as they would a dining-room table, while others consider any finish to be a waste of time. I fall somewhere in the middle, applying a finish more for protection than for the look it imparts.

Benchtops take plenty of abuse, so an easily renewable finish is in order. My home-brewed wipe-on finish dries fast and gives plenty of protection. Mix 1 cup oil-based polyurethane brushing varnish with 1⁄2 cup mineral spirits, then add about 2 oz. boiled linseed oil. Adjust the mixture with mineral spirits for proper wiping consistency, and then apply it like any other wipe-on finish. It will dry to the touch in about one hour. Three coats on a new workbench will resist water better than standard Danish oil; it’s a good idea to apply an additional coat or two once a year to maintain this protection.

My shop cabinets are varnished inside and out, so they don’t need much attention; however, they still get dings and scratches. Every couple of years, I vacuum off the dust and wipe on my home brew, which makes them look almost as good as new.

If your benchtop is made from layers of plywood or MDF, a better form of protection is to use a sacrificial surface. My benchtop is covered with 1⁄8-in.-thick hardboard held in place with double-faced carpet tape. When the top gets too dinged to be usable, I pry up the old piece and replace it with fresh hardboard.

Two ways to protect

Sacrificial surface

Benchtops made from sheet goods are best protected with a sacrificial top of hardboard, which can be replaced easily when it gets worn out (left). Use the old surface as a template to mark the outline on the new top (right).

|

|

A renewable finish that seals and protects

From Fine Woodworking #167

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Bosch 12V Trim Router

Milwaukee M12 23-Gauge Cordless Pin Nailer

Festool DF 500 Q-Set Domino Joiner

Comments

I have used and like almost all the methods in this article. I'm retired and in the past I shut down around Christmas and start working again as soon as the weather is warm enough for my fingers to move. the shut down last about three months so I give all the bare iron and steel a coat of CRC 3-36 to prevent rust. It came out on top in a test in this magazine. I built a sled out of MDF and tried to wipe a quick coat of shellac on to seal it before I waxed it. By the time I got it shellacked it had turned into a potato chip. I have had problems with the edges of MDF swelling just trying to glue it with full thick yellow glue. CA glue works well to reinforce screw and bolt holes and other places that MDF gets a lot of ware.

Log in or create an account to post a comment.

Sign up Log in