What’s Your Sign?

Readers, editors, contributors sign their work in distinctive ways

Synopsis: Many woodworkers like to “sign” their work so that future generations will know who made it. We asked around to see the different ways that readers and contributors to Fine Woodworking put their signatures to finished work. We found that as woodworkers, we use signing techniques as varied and personal as our work, from wood burning to engraving, carving, inlaying, stamping, and even Morse code.

You’ve spent weeks, months even, making that fine piece of furniture. You take pride in your work and want the world—or maybe just future clients—to know who made it. So how do you sign your work for posterity?

We put that question to members of our online discussion group, Knots (www.finewoodworking.com), along with some frequent contributors and FWW editors, and found that woodworkers use signing techniques as varied and personal as their names, and often as creative as their best work. Some go the cleanand-simple route. Some leave their mark with subtle bits of flair, while others get bold and brassy.

Here are some of the best examples and signing techniques that came up most often. Take your pick, or join our online forum and weigh in.

Wood burning

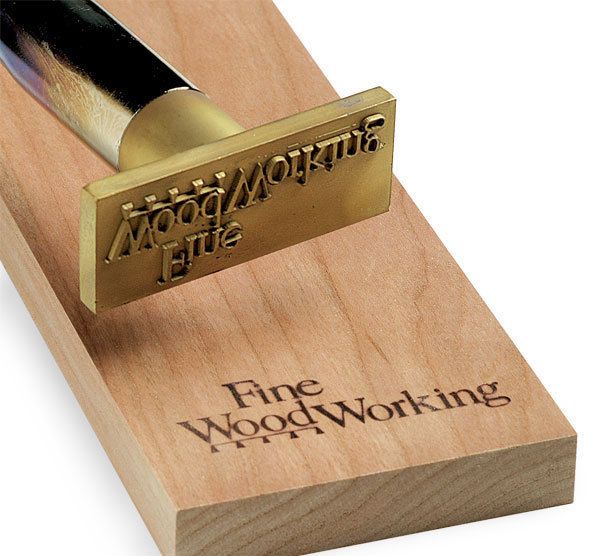

Burning a signature into the wood saves you the step of inking or staining in a dark color, and you get a choice of methods. In his Chardon, Ohio, shop, Bruce Schroeter uses an electric branding iron to stamp in his signature. These irons also come in the heatby-flame style, typically used with a propane torch. They’re less expensive than plug-ins but take longer to heat. In either case you get another choice: Just supply your name (as Schroeter did); or, for a higher price, supply your own design (as we did for the stamp in the top photo.)

Paul Weber of Tinton Falls, N.J., uses a standard, plug-in wood-burning tool. Its advantage? It allows you to restyle your signature for each piece.

Engraving

If block letters aren’t your style, it’s easy to “handwrite” a signature with an inexpensive engraving tool. Just turn it on and write with the vibrating bit. Vernon Blackadar of Lithia, Fla., smooths out any coarse wood grain with fine sandpaper first, to keep the bit from constantly bouncing off course.

FWW assistant art director John Tetreault engraves his signature on pieces of salvaged copper, and attaches them to his work with copper nails.

From Fine Woodworking #193

From Fine Woodworking #193

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Circle Guide

Blackwing Pencils

Log in or create an account to post a comment.

Sign up Log in