Synopsis: Timothy E. Ellsworth describes how to true and tune your metal plane, explaining how to lap the bottom, surface the frog, and file off burrs from nicks acquired over time. He explains how to set the opening, seat the chipbreaker, and make adjustments specifically to a block plane. Then he builds a wooden plane from the blank up. He closes with tips on remedying mistakes and defects in planes.

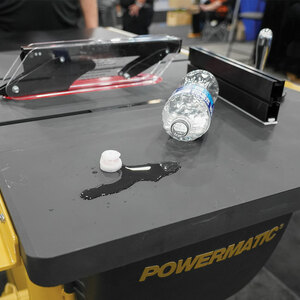

A plane is one of the most essential tools used by woodworkers and one of the most misunderstood. A simple examination of most modern planes on the hardware store shelf will be proof of this. The bottom will probably be warped and out of true by as much as 1/16th of an inch. There will be rounded edges around the throat or opening, and the chipbreaker will be very coarsely made.

The result is that a significant amount of remedial work is necessary to make the plane function. If the manufacturers don’t understand planes or don’t care about these potentially precision instruments, then how can the woodworker be expected to understand?

For those woodworkers who have been frustrated by planes or who have given them up completely, the following discussion might help. I am assuming some degree of familiarity with planes to the reader, but recommend Planecraft, published by C.P.J. Hampton, Ltd., Sheffield, England, for fundamental reading, as well as the booklet, Planes, published by Stanley Tools.

Let me begin by describing the qualities of a good metal plane, because that is what most people are familiar with. The bottom must be flat, really flat: no warp, no dips or hollows. There must be some provision for varying the opening, either by means of an adjustable throat (used in block planes) or a moveable frog (used in bench planes). The bearing surface for the iron must be flat and free of burrs and irregularities. There must be a cap iron or chipbreaker, except in the case of block planes. Adjusting knobs and lateral adjusting levers are normal on all but the cheapest planes. The steel in the iron must be of high quality, but this is rarely a problem.

Most of the planes that you will find in hardware stores will have uneven bottoms. There was a time when plane bottoms were precision surface ground, but cost cutting by manufacturers has, for the most part, eliminated this expensive process. The common practice now is to surface plane bottoms on abrasive belts. The result is a less-than-true bottom.

From Fine Woodworking #1

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Olfa Knife

Veritas Precision Square

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Log in or create an account to post a comment.

Sign up Log in