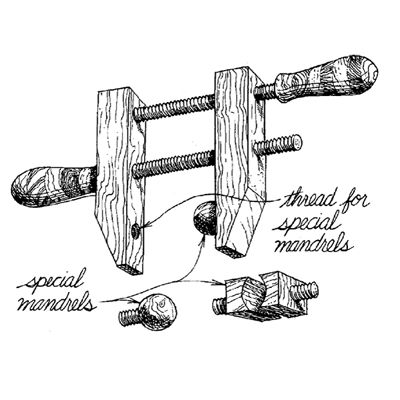

Synopsis:Richard Showalter makes children’s toys that collapse for easier shipping and storage. In making them, he perfected the art of making wooden screws, which paid off additionally in the manufacture of wooden clamps, which he explains here in detail. The scale you work on will determine the size clamps you need. Showalter talks about wood selection, preferred finished width of the jaw vs. the diameter of the screw, and which bits to use to drill holes in the clamps. He warns not to sand the piece until after it is completely threaded, lest you dull the thread cutters. Side articles detail threading tools and dowel makers.

During the six years I’ve been making my living as a woodworker, I’ve lived in a small town in Oregon, fifty miles from the closest city. The markets for the expensive children’s toys I make are still farther away and it became obvious very early that shipping and packing were going to be an important part of making my livelihood. I became interested in using wooden screws (Fine Woodworking, Spring ’77) as a way to make my work collapsible and more easily shipped. I bought a wooden threading tool and began making my own screws. They did everything I had hoped in making my work more portable and added to the value of the toy as well.

The most important spin-off has been the manufacture of wooden clamps. My shop is now equipped with a wonderful variety of them. They are fitted to my own hand, suited to my particular needs and esthetically pleasing to me by virtue of their materials and because they were fashioned in my own shop. The financial benefits are not to be despised either—it would cost hundreds of dollars to duplicate the number and range of clamps now at my disposal.

The scale you work on will determine the size clamps you need. If you want to make clamps corresponding to Jorgenson hand screws in the 8-in. to 12-in. range and want to buy only one threading set, the best size is 7/ 8 in. This makes a screw heavy enough to handle the strains of most applications, but still slender enough to be in proportion to a comfortable handle. One-inch screws make the clamp a little clumsy and the extra strength seems unnecessary. Wooden screws rarely strip. Most hand-screw clamps fail—when they do—by breaking at the center hole in the unthreaded jaw. If you work on a smaller scale, making instruments or doing similar, delicate work, the 1/2-in. and 3/8-in. sizes will make little hand-screw clamps as well as luthier’s clamps.

Clamp jaws may be made from nearly any hardwood. (I’ve even made acceptable clamps using yew, technically a softwood but a very dense and springy one.) Clamp jaws flex considerably in use and should be free of knots, bark inclusions and wind shakes. The slightest fault will be magnified by the stress of use.

From Fine Woodworking #8

For the full article, download the PDF below:

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Log in or create an account to post a comment.

Sign up Log in