Synopsis: Bernard Maas says that without a jointer, the other tools in the shop can’t fulfill their potential for precision work. He explains what a jointer is, how it’s made, its anatomy, and how to align its tables, change its knives, and last, how to use it to surface or edge joint. Side information covers more complicated uses for the jointer, including rabbeting, end-grain jointing, and tricks to help in various projects.

A properly tuned up jointer is essential for precision woodworking. Without the jointer to machine a straight, true and square edge or flatten a rough, irregular surface, the other tools in the shop can’t fulfill their potential for precision work. If you want to pull straight, flat boards out of the planer, you must start with a jointer-trued surface facedown on the planer table. If the stock is bowed or twisted going into a planer, the feed rolls will clamp it flat during the cut, but the wood will pop back to its old shape on the outfeed. A tablesaw is even more dependent on a jointer; without a straight edge to run against its fence, a tablesaw cannot be safely used. And, of course, when edge gluing boards, that last pass on the jointer guarantees a perfect joint. Even after the panels are glued up, the jointer can be of service, cutting rabbets for joinery and chamfering edges for a finishing touch.

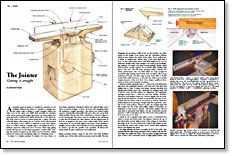

A jointer is a simple machine. It consists of a two-, three- or four-blade cylindrical cutterhead, infeed and outfeed tables and a fence, as shown in figure 1 above. However, this simplicity belies the machine’s complex geometry. The infeed and outfeed tables must be perfectly flat and parallel with each other and, across their width, parallel with the axis of the cutterhead, as shown in figure 3 on the facing page. The knives must be installed in the cutterhead so that they all protrude the same distance and the highest point of their arc is tangent to the plane of the outfeed table. If the various components are not properly aligned, the jointer cannot machine a straight and true surface and it therefore becomes practically useless. So, before I get into the specifics of its operation, I’ll discuss the jointer itself—its parts, maintenance and adjustment.

From Fine Woodworking #79

For the full article, download the PDF below:

Fine Woodworking Recommended Products

DeWalt 735X Planer

Festool DF 500 Q-Set Domino Joiner

Festool Rotex FEQ-Plus Random Orbital Sander

Log in or create an account to post a comment.

Sign up Log in