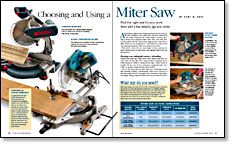

Choosing and Using a Miter Saw

Find the right saw for your work, then add a few helpful jigs and tricks

Synopsis: Should you buy a compound-miter saw or a sliding compound-miter saw? What size blade? With the range of options available in the marketplace today, choosing a miter saw can be a confusing task. More than a dozen companies make them, each with three to five models, in prices that range from $100 to $900. The key, advises finish carpenter Gary M. Katz, is to find the right saw for the work that you do. This article covers the two main types of saw, explores the most common uses for miter saws, and explains what saw best fits each use.

A good friend called a few weeks ago from a local tool store. He was looking to buy a miter saw, but was confused by the range of options and couldn’t make a decision. More than a dozen tool companies make miter saws, each with three to five models, and the various saws range in price from $100 to $900. Before you go shopping for a new miter saw, ask yourself one important question: What am I going to use it for?

This article covers the two main types of saw, explores the most common uses for miter saws, and explains which saw best fits each use.

Choosing a saw: cutting wide boards vs. tall molding

Twenty-five years ago, miter saws were called chop saws because that’s all they did: miter material with a chopping motion while having the ability to swing left and right. Today, nearly all models fall into one of two categories: compound-miter saws (CMS) or sliding compound-miter saws (SCMS).

Two of the main uses for miter saws are crosscutting boards and mitering molding. Unfortunately, there is no one type of saw that works best for both types of cut. Because of their inherent design, sliding compound-miter saws can cut wide boards but lack the height-cutting capacity of similar-sized compound-miter saws (see chart, p. 61).

Two ways to miter molding—When cutting miters you can choose to cut “in position,” with the molding leaning against the saw’s fence, or “on the flat,” with the molding lying on the saw’s table. The latter becomes necessary if the molding is taller than the vertical cutting capacity of the saw—a situation that has become more common as tall baseboards and historically accurate crown moldings grow in popularity.

To cut a miter in position, lean the molding against the fence at its installed angle but upside down, and swing the saw to the correct angle using the miter gauge at the front of the saw. Most miter gauges have about a 12-in. radius, which means you can dial in an angle to 1⁄2° without difficulty. To cut a miter on the flat, you tilt the blade using the miter gauge and the bevel gauge on the back of the saw. However, bevel gauges have only a 3-in. or 4-in. radius, so dialing in a bevel angle isn’t nearly as accurate—you’re lucky to get within 1°.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Milwaukee M12 23-Gauge Cordless Pin Nailer

Stanley Powerlock 16-ft. tape measure

Festool DF 500 Q-Set Domino Joiner

Comments

Any other sources for an extension table coupler, or even an explanation of how it works? The one in the article is from http://www.sawhelper.com, which is a dead website.

Log in or create an account to post a comment.

Sign up Log in