Get the Most From Your Jointer

Shop mainstay makes flat boards-and much more

Synopsis: Straight, flat stock is the foundation of any well-made workpiece. That’s why the jointer is such a critical piece of machinery for the shop. But in addition to milling cupped, bowed, or twisted stock to be flat, straight, and square, J. Speetjens also uses the jointer to taper legs, fit doors, and cut long chamfers, bevels, and roundovers. In this article, he covers the fundamentals of safe, effective jointer operation and then gives tips on how to get even more from this pivotal machine.

The process of cutting accurate, tightfitting joinery relies on beginning with straight, flat stock. It is the foundation of quality work. that’s why the jointer—a machine designed to straighten and flatten rough boards—is central to everything I do as a woodworker.

A jointer consists of a horizontal cutterhead mounted between two dead-flat, cast-iron tables that sit end to end. A board pushed lengthwise across the machine passes over the cutterhead as it moves from one table to the other. the outfeed table is set to match the height of the knives, with the infeed side slightly lower. this height difference determines the depth of cut. the machine quickly creates a flat face on a rough board or a straight edge that is square to that flat face, both crucial steps in milling cupped, bowed, or twisted stock to be flat, straight, and square.

But the jointer handles more than these core operations. It offers a convenient alternative to other tools that need special templates, jigs, or other lengthy setups to taper legs, fit doors, and cut long chamfers, bevels, and roundovers. Here’s how to get the most from this pivotal machine.

Follow the fundamentals for clean, safe cuts

There are some basic guidelines for operating the jointer safely and for getting high-quality results.

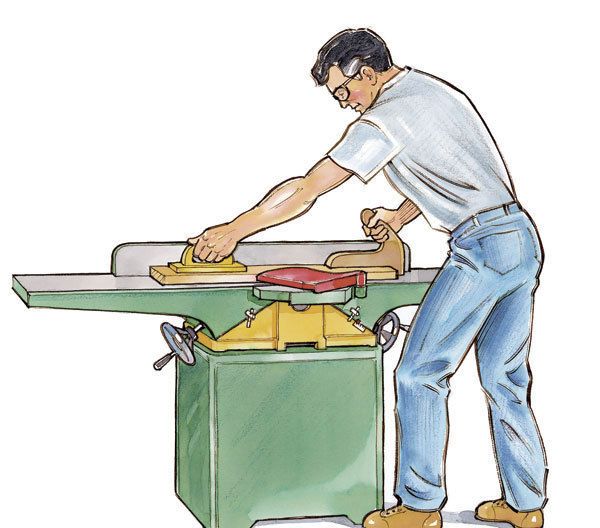

For safety, keep the guard in place and use a push pad and a push stick whenever possible to keep your fingers away from the cutterhead. I use a push pad and a push stick for all face-jointing operations and a push stick for all edge cuts on boards less than 3 in. wide. the minimum safe length that can be cut on most jointers is 12 in. Use a roller stand or other support for long or heavy boards.

For most material, orient the stock so that the grain angles down toward the infeed side of the cutterhead. For woods with inter laced or curly grain, make light test cuts to determine the best feed direction.

Concentrate on applying light downward pressure to the surface of the board as you feed it over the cutterhead at a moderate, consistent pace. Apply only enough pressure to prevent the board from bouncing on the cutter. If you deflect the bow or cup during the cut, it will remain afterward.

Feeding stock into the cutterhead too quickly will cause tearout or a wavy surface. but if you go too slowly, you risk dulling the blades or burning the wood. Stopping in the middle of a cut will leave a burnished dimple or a burn mark.

From Fine Woodworking #186

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid R4331 Planer

Stanley Powerlock 16-ft. tape measure

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Log in or create an account to post a comment.

Sign up Log in