Dust Collection Demystified

Choosing and configuring a system to fit your needs, with guidelines on capacities and suggestions for ductwork layout

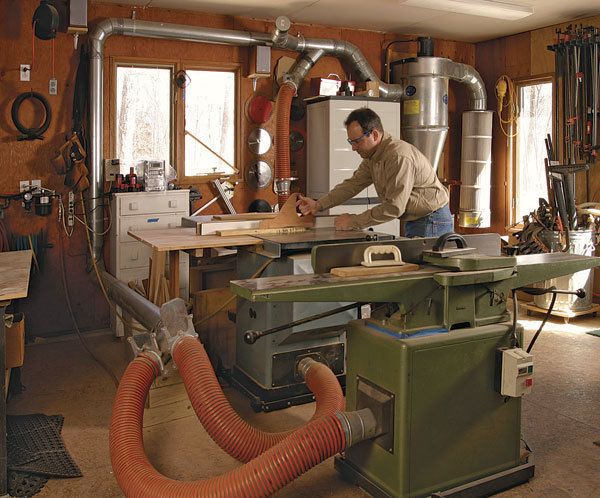

Synopsis: A dust collector performs an urgent and challenging task in the woodshop–it keeps the dust and chips produced by woodworking machines out of the air, off your tools and floor, and as a result, out of your lungs. This article aims to take the mystery out of choosing between a single-stage collector and two-stage cyclone collector. Both types will do the job if connected to the right setup of hoses and ducts. A test of the capacity of each type of collectors gives guidelines on which type of system will best suit your needs, and gives suggestions for layout out ductwork in your shop.

Woodworkers have been battling sawdust ever since the ancients invented the handsaw about 5,000 years ago. The Egyptians cleverly disposed of at least some woodworking debris by using it to stuff mummies, but this is not an option for today’s woodworker.

In more recent times, the dust and chips created by woodworking machines has grown vastly more plentiful, finer, and more hazardous. Prolonged exposure can cause respiratory problems and has been linked to the development of some types of cancer. So keeping all of this material out of the air and off your tools and floor, and gathering it for disposal, have become more urgent and more challenging tasks.

Enter the dust collector.

A woodshop dust collector is a simple exhaust system. Its blower moves contaminated air through hose or ductwork to filters, which clean that air for recirculation back into the shop. The more effective the blower, the more ductwork you can add and still have enough suction at the other end to do the job.

For many woodworkers, a shop vacuum is the first dust collector. A shop vac can handle small amounts of fine debris like that produced by a 5-in. orbital sander or a router. But a shop vac moves small volumes of air, making it a poor choice for larger stationary machines.

Dust collectors generally belong to one of two families. Single-stage collectors carry the sawdust and other debris directly through the fan and into filter bags or cartridges. Two-stage cyclone collectors allow heavier debris to drop out of the airstream before it reaches the blower, meaning less work and abuse for the fan and filters.

The more air a dust collector moves, the more debris it can carry. Dust from a small hand sander might be captured effectively with as little as 100 cubic feet per minute (cfm), but a tablesaw might require 800 cfm. Also, the faster a collector moves the air, the heavier the debris it can carry. The lightweight dust from a small sander might need an airspeed of as little as 3,000 linear feet per minute. The coarser material produced by a planer often demands as much as 4,000 fpm. Finally, the more effective a dust collector’s filters, the less fine dust will be returned to the air.

From Fine Woodworking #188

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Hedgehog featherboards

Rockler Dust Right 1250 CFM

Log in or create an account to post a comment.

Sign up Log in