Classic Woodworking: Shaker-Inspired Hall Table (101)

This video is an episode teaser. You can watch full episodes on our website by becoming a Fine Woodworking member.

Already a member? Log In

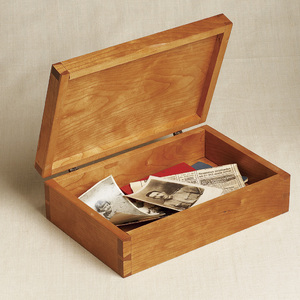

In this premiere episode of Classic Woodworking, host Tom McLaughlin builds a classic Shaker-inspired hall table. Made of cherry, the piece features iconic Shaker details, such as mortise-and-tenon joinery with wooden pegs for strength and looks, and elegantly tapered legs to give the table a slender appearance. Simple to make, and at home in any décor, this piece is sure to inspire.

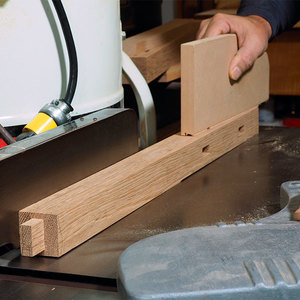

For details on Tom’s leg tapering jig, see the article How to Make a Simple Leg-Tapering Jig.

For details on Tom’s leg tapering jig, see the article How to Make a Simple Leg-Tapering Jig.

See Tom finish the legs with a handplane in this video, How to Handplane a Taper to Perfection.

For more information on how to make a pegged mortise-and-tenon joint, see the article The Pegged Joint, Exposed.

To see other tabletop edge profile designs, see the article The Right Edge for Your Tabletop.

To learn how to get more from a polyurethane finish, see the article How to Get Better Results with Polyurethane.

For secrets on finishing cherry, see the article Blotch-Free Cherry.

Download free plans, or purchase a set of printed plans (coming soon).

Comments

What happens when you ship that table to Florida where it is humid and the table top wants to expand? Shouldn't you attach the top with slots to accommodate wood movement?

just watched this first episode. liked it. but, a few things...

01) i agree with the comment above. tom made no mention of wood movement.

02) finishing. while i understand that finishing could take up the entirety of each episode, if these shows are to teach as well as inspire, SOME mention of issues regarding finishing are warranted. especially when using a wood like cherry which is prone to blotching.

03) the lighting. the lighting in this episode seemed really flat at times, with some detail "washed out".

that said, i'm looking forward to future episodes. it's a nice start to what i hope is a long run.

Agree with 1st comment - should have discussed wood expansion re top attachment. Also, why did you use a wet rag to clean up squeeze-out? Most glue-up articles say not to.

Congratulations to Tom and Fine Woodworking for a great show. I hope Fine Woodworking is going to continue showing the rest of the episodes on the site, because the show doesn't air where I live in the Saratoga NY area. Looking forward to the next show.

Great first episode!!! Tom is a great addition to Fine Woodworking and will be an awesome host for the Rough Cut show. Hard to get every detail in a 30 minute show. Nice to see a professionally produced show. Please keep posting online as my local cable company has not picked up yet. Steve

Bravo Tom! And, thanks to FineWoodworking for sponsoring this valuable series.

Hi guys,

Good questions, glad you enjoyed the first episode. Sorry we don’t have enough time to cover all the details in the 26 minutes we have for each show. Hope you’re not more frustrated when we cover more complex projects as the episodes move along this season :)

There’s lots of support material, and links to expounding articles included above.

As for the wood movement issue. The screws at each end, in the center of the short rail don’t move at all. While the three screws along the long rails run in through holes that are reamed out a bit from side to side to accommodate for the minimal movement. With this arrangement, the top will only move from the center or the width out to the rail, approximately a 7” span. The reamed holes are more than enough to take care of that, even moving to a high humidity area.

And as for cleaning off the glue, wiping with a damp cloth (not soaked) is fine to clean off the glue. You want to wipe just enough to remove any glue haze, especially when using waterproof Titebond III as I used when gluing up this table.

Another method is to allow the glue enough time to get rubbery and remove gently with a putty knife. The third method, I don’t recommend, is waiting for the glue to harden and scraping off with a paint scraper ore equivalent because this method often lifts and tears out wood fibers from the surface along the joint which can be a challenge to repair.

Thanks again!

Tom McLaughlin

Great first episode. Much more woodworking quality than the "old" Rough Cut episodes. Poor video quality, is there no HD version?

I have liked Tom McLaughlin since he would guest host rough cut in past seasons. This first program I have been waiting for all spring since he was announced as the host for the show. He is knowledgeable, clear and concise in his instructions and steps. Definitely getting my subscription to Fine Woodworking!

Hi guys, Good questions, glad you enjoyed the first episode. Sorry we don’t have enough time to cover all the details in the 26 minutes we have for each show. Hope you’re not more frustrated when we cover more complex projects as the episodes move along this season :) There’s lots of support material, and links to expounding articles included above. As for the wood movement issue. The screws at each end, in the center of the short rail don’t move at all. While the three screws along the long rails run in through holes that are reamed out a bit from side to side to accommodate for the minimal movement. With this arrangement, the top will only move from the center or the width out to the rail, approximately a 7” span. The reamed holes are more than enough to take care of that, even moving to a high humidity area. And as for cleaning off the glue, wiping with a damp cloth (not soaked) is fine to clean off the glue. You want to wipe just enough to remove any glue haze, especially when using waterproof Titebond III as I used when gluing up this table. Another method is to allow the glue enough time to get rubbery and remove gently with a putty knife. The third method, I don’t recommend, is waiting for the glue to harden and scraping off with a paint scraper ore equivalent because this method often lifts and tears out wood fibers from the surface along the joint which can be a challenge to repair. Thanks again! Tom McLaughlin

I also loved Tom's appearances as a guest on the show so I was looking forward to him hosting it. Excellent job! I liked professional attitude, good clear explanations and the inspiration coming from the host with a lot of real furniture making experience. Thanks, Tom and FWW!

Tom, you show glue removal on the top but, in your opinion, what is the best way to remove glue on the side with the clamps? Flipping a well clamped glue up that size works but there is still glue in hard to reach area around the clamp bars. Larger projects like big tables often can't be flipped.

I was looking forward to this and was not disappointed. Yes there were a couple of items not shown but I believe some one with basic woodworking skills could complete this and be proud of their work. Keep up your good work. I like the links to articles to aid this project.

This is a great video, and you look as though you are really enjoying it. Great design and execution with a very clear commentary. You are a natural teacher. A couple of thoughts. I seal the wood around mortise and tenons so that the squeeze out doesn’t penetrate the wood. Second is, you cut your dowels off sawing into your left hand. I always cut away from my body without exception. Even when I think I’m in complete control, which you obviously were. A beginner may not be so.

WHAT? How are you on season 8 and I am just finding out about this show! I hope the other seasons are still available to watch somewhere. Great show!

Not everybody has long clamps. Originally those pegged mortise and tenon joints would have been draw-bored, negating the need for any clamps.

What a great first episode.

I have been eagerly awaiting the new series of Rough Cut with Tom McLaughlin and it was well worth the wait.

Very well done all around. Thanks!

I hate to have to say it, but I thought this episode was terrible. Tom's great - he's a likable fellow who clearly knows his stuff. The problem is the photography and the editing. How-to shows are supposed to show you HOW TO do things. Not just show you the host's smiling face as he does "something" out of frame. Don't gloss over the details! Show them to us!

If you are making this show to teach people about woodworking, I would be surprised if anyone learns anything from this episode. If you are making the show for people who already know how to build the projects (and therefore don't need to see as much detail), then what's the point? I'd rather be working in my shop than watching a video of someone else working in theirs, if I'm not going to be able to learn anything from it.

I recommend that whoever is shooting, directing, and editing the show go back and watch a few seasons of "New Yankee Workshop" to see how to make a good, informative woodworking show.

Tom,

I was surprised to see how you are using the sliding table saw. It isn't a cabinet saw and a slider offers many advantages over one. I realize few people have sliders -- perhaps that's why you have mounted cabinet saw accessories, such as a cross cut sled, to your expensive slider? And while your tapering jig is fine for a cabinet saw, why not show how to use a slider to more accurately, and flexibly, create tapered legs ala this method: https://www.youtube.com/watch?v=GWOGzxuz8rc?

I realize you have limited time, but it seems that you are currently spending no time discussing the unique aspects of your sponsor's equipment. Wouldn't your viewership benefit from understanding the unique characteristics of your sponsor's equipment and why they might choose a slider over a conventional table saw?

What a vast improvement with Tom McLaughlin! Finally, someone who isn't confused about whether he is doing a woodworking show or a cheesy "buddy movie." Show what you're doing and save the lame humor for your family!

Having only seen the first episode, and bearing in mind that time constraints limit to some extent the amount of detail you can discuss and demonstrate in any one episode, I will offer a couple of thoughts based on my impressions of the show to date. You might suggest some other methods to perform tasks.

For example, if you don't have access to a mortise, you can make mortises this-or-that other way. Or, if you lack a jointer, here's another way to achieve a true square edge.

I would also agree with the previously expressed sentiment to consider covering one project over multiple episodes, or have further detail on projects available on this website.

I do appreciate the time and effort that you are devoting to this show, and I hope that you will accept my comments in the spirit that they are offered.

I discovered this show a few months ago and watched a couple of episodes featuring the old host. I have to say, I did not enjoy it that much because I did not really like the host and the shop renovation project did not interest me. The new show is awesome. The host is great, and the projects are exactly what I'm interested in. I'll be watching every episode multiple times. Thanks to Fine Woodworking and the sponsors for doing this show.

Why in the world is he using a sliding table saw like a cabinet saw?

Are you assuming that your viewers are stupid or wouldn't understand the clear advantages of using a sliding table saw?

If I was a sponsor like Felder I would want my money back.

Just watched this first episode with my wife in our home in Sweden! We're big fans of Tom McGloughlin and his work, and are so happy to see him as the new host of Rough Cut. His knowledge and skills in fine woodworking, as well as in teaching make him a master for guiding us through the building of some really beautiful pieces. I look forward to constructing this table, my wife just ordered it. :) Thanks for a great first episode, Tom, we look forward to the rest of the season! And thanks to Fine Woodworking for making it possible for us to watch in Europe.

All the best, Pär and Caroline

I just found this first episode. I like Toms teaching and the episode moves along at a good pace. I for one am quite shocked That there is no mention or safety recommendation regarding dust collection and keeping it out of your lungs. Several of those cut sequences show a LOT of sawdust coming up and Tom not wearing any dust mask. I understand that makes it difficult to speak but voice overs can be accomplished in post editing. At least include breathing protection in the graphics with the eye and ear protection.

Some of the comments regarding screwing the top to the base and wood movement could have been included in the episode as comments while drilling. I noticed several other spots where this type of side comment would be beneficial to the viewer. Overall, i like the new show and will continue to watch the other episodes.

Very nice Tom, 2 thumbs up for the 26 minutes of air time you have.

Log in or create an account to post a comment.

Sign up Log in