Advice from those who’ve built doors

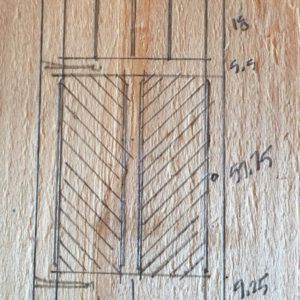

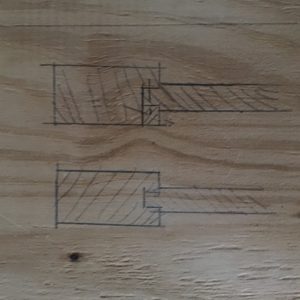

I’m building a door for my garage from scratch (first image). First, I’m trying to determine if rabbeting the lower panels in and using sticking on the backside would be as stable as T&G? (Second image). I’d assume the first option would be easier to execute and I would prefer, but don’t want the door to shift over time. Lastly, have I left enough room at the edge of these rails and stiles for the mortise and tenons (third image)? It about 1/2”. The last and final image is my prep so far. Any suggestions would be greatly appreciated.

Replies

Your biggest issue will be sagging. If it were me, I would do tongue and groove, and plywood for the panels, glued all around. Solid wood panels that float in the grooves add no strength, and the dominos don't help.

Original doors would have had much wider through tenons, and resisted sagging much better.

Good to know. I’ve assembled the panels as 1x6 t&g v-groove. Wanted a more authentic look. Should they be loose? Good to know about the tenons though. I’m using 1/2” x 1-1/2”x6”oak. The door frame is Doug fir. Should I go to a 3 or 4” single tenon instead? Thank you for your feedback!

I have built many interior and exterior doors. My standard is 3" deep tenons on the outer rails and stiles. I have had no issues with sagging over the years. I have done lots of reading on making doors as well and the recommendations I have come across for doweled joints is a 4.5" deep dowel on each end and spacing them out about every 1". Your dominos are similar to dowels with more glue surface. I suspect the joint pictures will be fine.

All of my exterior doors use solid wood floating panels without issue. I do add soft foam around the groove to help with air sealing and expansion.

I would definitely go with t&g. It looks much better than adding in the little piece on the back. I've done it both ways, but only use a groove now.

I think your plan will be fine and similar construction methods have been used for over 50 years without issue. I would recommend a ridged, waterproof glue for all your joints, like polyurethane (Gorilla) glue. I've had better luck with that over Titebond 2 on softwoods outdoors.

Please post a picture of your finished door, it is looking good so far and I'm interested to see your results.

Thanks Jake, John for the input. T&G it is for those panels! I’ve been using titebond 3. It’s a 4’6” wide door so obviously I’m trying to keep them as solid as possible. They’re also just shop/carriage doors, but I’d rather avoid any fit and operation issues down the road. I’m also hoping strap hinges will provide assistance. Will post the final result.

Did you write 4 1/2 foot wide per door? That is 54 inches, the standard door is 30 inches. Let’s do the math , say the standard door width weighs 100 pounds, the torque applied to the joints by its weight is roughly 100 pounds X 15 inches so 1500 in.lbs . The wider door is heavier and has more leverage on the joints, say it weighs 150 pounds centred at 27 inches, it then applies 4000 in.lbs of torque , that is close to 3 times the load. Your tenons are small compared to a light duty door, you may want to have a diagonal strap on the backside .

Gulfstar: so should I go to a larger, single tenon at each joint? I haven’t cut the mortise pockets yet.

Well you definitely want to get the most out of the mortice and tenon assembly. But there are issues that need consideration in the design of the door construction first.

The 3 solid wood panels need to be free to move in the frame so if they expand, they will not push the mortice and tenon joint open and if the contract in dry weather, they will not crack. On your second picture, the tongue and groove design does not allow for wood expansion so if the top panel goes through a wet season and gains 2% of moisture it will get 1/4 inch wider so something will have to give, likely the frame joinery. therefore the groove width needs to be the same as the panel thickness and the panel not glued in the groove and should be able to expand and contract at least 1/4 inch either way on the width.

So the frame strength is the only means to keep the door from sagging, the panels are dead weight. The center cross piece is your main structural member since you can make a full width tenon on both ends. The end cross pieces, top and bottom are wide but the mortice should not get to close to the ends of the uprights and become your weak link, for that you need to make a step tenon and mortice like the attached picture.

There are other solutions to mechanically strengthen a frame, using plywood panels glued in the grove is one as mentioned previously. Using diagonal bracing is another, but each will affect the design.

Using better adhesives can also go a long way, I use marine grade epoxy thickened with fibrous silica (carbosil) it has he advantage of leaving me a good half hour of working time in the glue-up.

That's why I would go with the bigger mortise and tenons, and glue in plywood panels. Essentially making a monolithic door that looks like frame and panel. Then you still need to make sure the jamb is really solid, and have really heavy duty hinges. Ball bearings. You won't find hinges like that at the home center.

Gulfstar: Thank you for sharing your breakdown. I'll swap out the bottom rail for something taller. I imagine pinning the tenons will help strengthen the joints? Also, I already have the T&G v-groove panels glued; so, I'd like to use those if possible. I can fit those to leave room for expansion/contraction. I guess I could also use marine grade plywood and route in the grooves. See image for revised construction.

John: Yes, I have heavy duty strap hinges coming from RW Hardware. I'll beef up the jambs and anchor in my hinges sufficiently.

Thank you all for the great advice. Glad I came here before putting this together!

You need room for expansion where the panel meets the frame also .

Perfect. Will make that adjustment. Thanks again!

With solid wood panels you need to allow for movement. Attaching like you're wanting to do is an excellent method because is allows for removal of the panel is ever needed.

If you make the rails wide enough *and pin them* you won't have an issue with racking.

This forum post is now archived. Commenting has been disabled