Angle gauge with hand plane thickness jig for accurate tapers

So, I am getting ready to start building a crokinole game board out of some boards I have on hand. The boards are old maple flooring. For this project, I am going to be taking the tongue and groove out. For this, I am going to need to make some very accurate tapers.

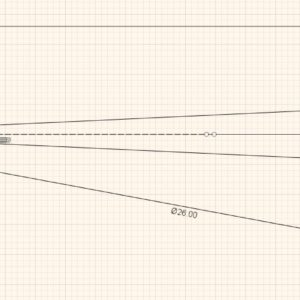

My plan is to make some aluminum angle gauges with a mill equipped with a DRO. This isn’t going to be an issue. Do you guys think this would work well with using in a thickness jig for a jack plane? I need to make 68 pieces with a total included angle of 5.294°. For this, I am going to need to make two sets of gauges. Each set is going to be a pair, with the 2″ wide blade, I can do 2 boards at once. One set at the 5.294, and another set at half of that. The boards are not going to come to a point. Granted, they are only going to be about 0.032″ thick at the end. I am planning on dropping a solid piece for the center hole that is only supposed to be 5 or 6 mm deep.

Am I at least on the right track, or should I go about this an entirely different direction? This planned method seems that it would eliminate the most time at my makerspace. Not that I have an issue going there, but work and family time prohibit most times they are open.

Including a picture of the piece I need to make with dimensions from Fusion360.

Replies

Quick follow up question. If I use this method, which direction should I work toward?

This forum post is now archived. Commenting has been disabled