Hello,

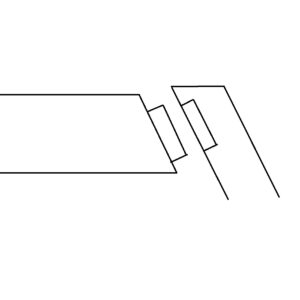

I will try to build a table using angled mortise and tenon joint, but I am not sure what would be the best way to cut it, since I do not have a lot of experience with joinery.

1. My idea is to chop the normal mortise at 90 degrees and change the angle of the tenon to match the angle of the table legs. Or is there a better way?

2. Since there are two stretchers left and right, I was thinking to connect the upper stretcher first (without gluing it of course), mark the length on the lower one, and cut the lower stretcher and mortice and tenon. Then I can assemble everything together.

Or is there a better way to tackle this project? Thanks.

EDIT: I do not have machines, I work with hand tools only.

Replies

I'd go this way

I understand it is more stable, but much harder to cut.

It is easier then you think.

Make a wedge. the wedge is used underneath the leg while morticing.. it holds the leg at the proper angle and is repeatable. While morticing with a chisel, keep it plumb to the bench. To help with keeping plumb put a try square or combo square behind the workpiece on the bench to help sight the chisel to know what plumb is. The wedge can also be used to hold the leg at the proper angle on a drill press to remove most of the waste or with a router box if morticing with a router or a hollow chisel mortiser. The wedge can also be used on the table saw to cut the angled shoulders on the horizontal members. Once the wedge is created nothing everything else is kept at 90. the legs in the pic looked to be tapered (outside).. the tapering needs to be done last after the joinery...

here is an article that uses a wedge.. though the article has through-tenons.. the use of the wedge is the same.

https://www.finewoodworking.com/project-guides/tables-and-desks/arts-and-crafts-coffee-table-with-story-book-charm

Making wedge is a great idea!

I'd do it mj's way. I don't see how it's more difficult.

I have made many splay leg shaker style tables with no leg failures yet. I use floating tenons cut using a shop made jig. I cut the leg mortise with the leg square. Then I taper the leg up to the intersection of the leg and the taper. This reduces the angle of the intersection between the leg and the apron. I cut the ends of the apron to around 2 degrees although I have used as much as 5 degrees and as little as 1 degree. The mortise is then cut into the end of the apron. The floating tenon fits well into both mortises and simplifies the problem of cutting either an angled tenon or an angled mortise.

I guess floating tenons would be the solution, if I was working with machines. But I do not see how they are easier to do using hand tools, especially since the angle has to be nearly perfect in order not to have gaps.

If you're using hand tools only, I would use a brace and bit to drill out the majority of the waste. Practice first using squares to align the drill bit.

I don’t think either would be that difficult to do by hand. Set a bevel gauge mark and pencil line on the outside of your mortise and use your eye if your want the mortise to be angled. If it is the tenon to be angled, not that hard to cut by hand once marked by the bevel gauge. The sides of the mortise and tenon are the biggest glueing surface so if the ends aren’t a perfect fit, it shouldn’t matter much. Good problem to have I suppose.