You regulars to this forum might remember the various questions I posted about my MCM buffet. My project turned out better because of all the help.

The buffet is pretty much finished. The pic below shows it on my bench. I still need to add the back (walnut veneer plywood), but overall I’m pleased with the results.

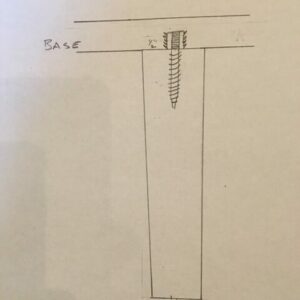

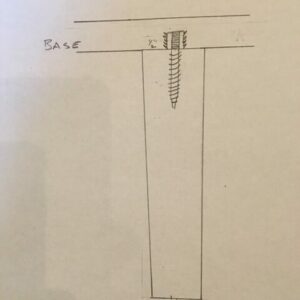

I attached the legs and am concerned. The legs are 7″ long, about 1 3/4″ wide at the top and taper. My issue is that they are wobbly now that they are holding up the buffet. I used hanger bolts (bolt thread on one end, screw end on the other) and screwed them into those little anchors that you put in the base and screw the bolt into. Picture attached to compensate for my poor descriptive abilities. The problem is that my base is 7/8″ thick and the anchors are only 1/2″. I drilled as small a hole as I dared. The anchors I used were the ones you hammer in, not the threaded kind. The weight of the buffet makes the legs wobble.

I know it will sit peacefully in one place with no problem. However, eventually it will be moved and people (like me) tend to shove furniture to move it, not lift it. Those legs will pop out pretty easily I fear.

What to do? I like the clean lines and don’t want to add thickness underneath unless absolutely necessary. I also can’t put a washer and nut on them since the legs are right under the grooves for my sliding doors. I need some good advice! Thanks!

Replies

Unfortunately, you seem to have painted yourself into a design corner. A possible solution might be to redesign the legs and incorporate a thick apron with good M&T joinery. This might keep the legs stable while not detracting too much from the design.

Good advice. I've been scrolling through yahoo pics for 'Mid century modern buffet' and it turns out most of the leg designs have some sort of apron or rail between the legs. Now I know why.

Looking good, and the leg positions are fine!

That sort of leg is usually held on to a metal plate, though it also uses a hanger bolt. You can get them at angled or straight - they add only 10mm thickness so a half-inch bead would hide them.

https://www.ebay.com/itm/322462145890 This has the advantage of making the legs easy to remove and replace if damaged.

Alternatively, you could get 1mm steel plate, drill a central mounting hole for the leg and four holes for screws.

Final option would be to turn the top 1/4 inch of the leg or so to true round and rout a corresponding socket in the base to glue and screw. You might even get away with 1/8 inch if the fit is very close. All you need is just enough to relieve the pressure on the screw in the event of lateral forces (say when someone tries to nudge the cabinet sideways when loaded)

Selby has them in straight and 15-degree angled versions.

https://www.selbyhardware.com/leg-mounting-plates/

This forum post is now archived. Commenting has been disabled