Good morning i would like some help with this bevel cut on band saw . I tried couple things and didnt work out well 😀 obviously v groove and only half work on square lamber . Even if there is a jig for that to make . Can you guide me please? how to cut this mid section bevel? tools i ll need ? old school takes too much time to make to much refine it after . Thank you very much .

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Replies

You could mark precisely the contour. Crosscut the ends with a hand saw to the lines, then the tilt the bandsaw to 45 degrees and cut out the middle section entering from one side then flipping to remove the leftover.

You could also use a slightly oversized square, rip at 45 degrees and glue back the ends and plane it down to the desired square size.

Cut out a small pirce in the mid section and then flip it to from mid to edge? Or just cross cut mid turn the wood to the lines? Ledt and right?

I personally wouldn't do that on a bandsaw. Too much finagling. You could figure out a way, but I wouldn't bother.

I would redesign it slightly, and just bevel the entire edge. There really is no reason to leave the two ends square.

The edges will be 4 inches long is for elbow stand when you type letters or foil pressing in book spine

The idea os good i ll male test cuts until i find it out :D of i add the end piece will it hold? With dowels as press?

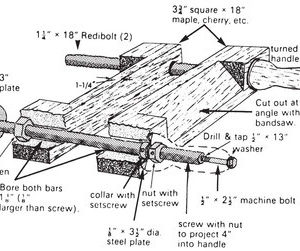

Here is a jig that would work on the bandsaw. Personally, I would just cut it out with hand tools.

Looking at my tablesaw and crosscut sled, it would be very easy to cradle it in a V-shaped shopmade jig and remove the waste with multiple passes. Very time consuming and tedious, but it would give you the clean bevel cut you are looking for.

With the assumption that you have a tablesaw... Make Vee-blocks to hold the part at 45 degrees and nibble it away on a crosscut sled.

I'm with Robscaffe...I'd probably do it by hand and be done before the jigging and testing was over.

I have evolution rage 5s tablesaw scroll saw and bandsaw. V groove sled on table saw yes ll be time consuming.am looking Robs jig with the cups

Pretty much same story with table saw but also work with angle cut str8 center left center right

If you have the v block on the tablesaw sled, just cut both ends of the gap with it and bandsaw away the bevel in two passes. Or nibble away the width of the band saw blade and bandsaw away in one pass.

I ll try all 3 options thank you guys for everything

It's all long grain. Cut the bevel on the table saw, and glue the ears back on after. Saves a lot of fussing, and it's only a jig, not fine furniture.

Its a press ll it stand the handle tighting threw the rod ? The big one ton the smalls in colour pictures but i can always go on router and buy a big 45 bit and let it go

This is a bit off-topic, but that whole thing looks like a standard handscrew. You might save a boatload of time and effort by tearing one down for your hardware.

Now that the idea is in my head I'm going to break one down to make a mini-moxxon that I've been noodling on for a bit.

My first thought when I saw the picture was Moxon vise.

This forum post is now archived. Commenting has been disabled