Bandsaw switch is not reliable

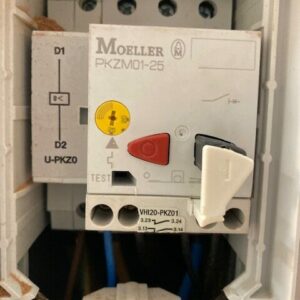

I have a Minimax 16″ Italian made bandsaw. Nice machine, except that from time to time the switch ( the white thing in the photo) won’t catch when pushed in — best way I can put it. Machine won’t turn on. Usually with perseverance I can get it to work, but today no go. I don’t know of anyone who could come and fix this. I mean maybe my electrician, but it is sort of a weird switch so I just don’t know. I took the cover off the switch long ago to make it easier to fiddle with, and I keep the switch area vacuumed out.

As is obvious from this post I am not handy with electrical stuff. Anyone out there familiar with this switch ? Had similar problem ? Solution ?

Replies

Wow, pretty nice saw to have a bum switch.

It may just need to be replaced. Or possibly have the contacts inside the switch cleaned. I have seen some switched that have had the contacts arc when closing and over time they burn then stop working.

Can you see inside the switch the contact is made? Try taking that apart and checking it.

You have a device that is more than just a switch. This is the description from Moeller, the manufacturer:

"The PKZM1 is a 3 phase thermal magnetic motor protective device incorporating bimetal trips for motor overload protection and magnetic trips to de-energize the motor circuit in case of a short circuit. It is UL Listed and CSA certified as a HIP rated manual motor controller which provides motor running overload protection."

The Moeller website says the part is obsolete and to contact them for an alternative.

I would do a bit more research before opening it. Likely it is not serviceable. On the other hand if it is already u/s opening it won't hurt. Good luck.

For a single phase thermal magnetic motor protective device, a rubber mallet is the proper tool for fine tuning. I'm not sure for three phase though.

LOL! The metal version of that device is sometimes known as the "John Henry Adjustment Wrench".

I have/had that same switch on my MM 24”. I replaced it once. It never was right. I fought it just like you do. I finally pulled it and all the ridiculous cut off switches on the upper and lower doors. I now have a switch that works every time.

OP here. Just called SCM, which bought MiniMax, hashed it out with a parts guy, turns out I need the switch, plus coil, plus reset, for a total of $254 plus 23 shipping. And he can't tell me that all this is any more likely to hold up better that the original switch. Not a happy camper.

Can you tell me what exactly you did to get around all this ?

Do you remember how the Moeller switch mounted in the plastic carrier? Was there a DIN rail, or did it snap into some features on the carrier?

The safety switch you have is there to protect you, or someone else from injury or worse in case there is a malfunction/short/power failure, by the motor automatically restarting when the power is restored. That is very dangerous. If you're confident in your ability to always remember to turn off the switch and/or unplug the machine after a power failure, etc. then you could replace it with a simple on/off switch of the proper configuration. Since someone's pointed out that this problem is known by the manufacturer, I'd suggest contacting them first. There are also after-market devices available in woodworking catalogues you could plug your machine into if you just replace your safety device with a simple on/off switch. Some only handle one machine, others handle two.

It is likely that the solenoid that pulls in the contact when you push the start button malfunctions. To find out you can remove the front cover and push the contact that is normally drawn down by the start button using a piece of wood or plastic and if the machine starts, then it is the solenoid coil. There are magnetic switches available on Amazon that can be used as replacement but if you are not at ease with electricity, you need to get an electrician.

I have the same saw with the same switch. The only time I’ve had the switch not engage or “catch” properly is when either the upper or lower door aren’t closed properly to engage the safety switch each of those doors are equipped with (to prevent saw from being started with either door open). I’m sure you have already checked this, but figured I’d throw it out there just in case! Might just be a bad switch. Good luck!

While not familiar with this saw, I have had other switches where fine sawdust infiltrated and prevented good contact. Opening and blowing the dust out cured the problem.

I am currently having a dust problem in my table mounted Bosch router, although I have not taken the time to take it apart and clean it.

Wondering how you resolved this? If you replaced the switch, do you remember how the Moeller part attached to the plastic carrier? Is there a DIN rail in the carrier or does the Moeller switch just snap into features on the carrier?

I've got the mm16, and I'm on my 3rd switch. I agree that it's a nice saw, but the switch seems to be a weak point. The first two lasted 12 to 18 months each. But this 3rd one has been good for a few years now. Perhaps they've improved?

Dunno - but I was just quoted $118.00 for the same AEG Mbs 25 switch, from SCM. I'm not gonna spend that kind of money for something with such a bad track record. The impression I get from internet search, is that the original AEG switch may have gone obsolete. It's possible they're being replaced with a Moeller/Eaton PKZMO-25.

A bad power supply, broken power cord, failed on/off switch or bad drive motor can prevent the band saw from starting. Check the power supply first. Plug a shop light or other electrical tool into the electrical outlet that you're using for the band saw to make sure the outlet works. If the electrical outlet is dead, reset the house circuit breaker for the outlet.

liteblue

Here's a picture of the fused switch contact - thanks for imparting your electrical knowledge!

This forum post is now archived. Commenting has been disabled