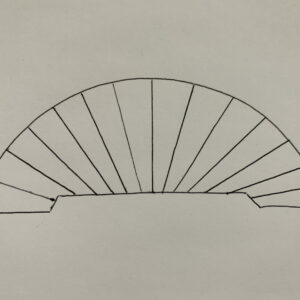

I’m new to FineWoodworking and have truly enjoyed the learning. We are building a bartop out of White Oak and it will feature a sunburst pattern. The bartop is large – 9 feet long and 30 inches wide (oval shape). At the focal point of the sunburst pattern the boards will be more closely jointed that on the periphery. We are concerned about shrinkage and expansion of the oak (especially at the focal point) and are worried about how the boards will attach to the underlying support (plywood or MDF)? Any advice on the best way to attach this white oak bartop to the underlying support? Thank you!

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Replies

How thick is the bartop? Is there any overhang? Are the boards glued up with some kind of doweling - dowels / biscuits etc or just edge to edge? Edging or nosing or endgrain exposed? Finished how? " Bartop" makes me think wet...I'd stay away from mdf to start. Does it need to be fastened to a substrate at all ? ( How is the base constructed? ) By " more closely joined" you mean they taper? ...but joined edge to edge just the same...Are you going to glue this up as a rectangle and then cut to shape to simplify clamping but waste alot of wood or are you going to build it up to the shape and do some tricky stuff to glue it together?

In terms of thickness, we are using 1 inch thick white oak (planned down to 3/4) and the support plywood underneath would be 3/4 - 1 inch also. We were planning to glue up the oak, edge to edge (but wondered if biscuits would be needed). We will have an edge molding (also white oak) that could be be capped over the bartop surface to hold it in place. Yes - the boards will taper which is what we meant by "closely joined". Yes - we are planning to build it out in a rectangular shape and cut the edge to form the oval. Thank you!

Ok. Problem with your design. If you do it with the oak that thick and on a sub base like plywood, it will blow apart. The movement from the oak will overpower the base with seasonal movement. Even without a base, it will not work. You have the grain going multiple directions which is the issue. I did a job with a similar concept, as in grain going different directions, red oak 1/4" thick glued to 3/4" plywood and the joints between pieces grow and shrink with seasonal movement. I would make your pieces as thin as you can, veneer, and glue them that way. I just finished another job a few weeks ago with the same design but only 1/8" thick. Hopefully it will do better than my last attempt.

Agreed. This is a veneer project if you ask me. I’d resaw to 1/8” or just buy some veneers and have fun with that.

Or if you’re cool with a looser look, I’d make battens and just use screws, no glue, and let there be gaps where gaps wanna be and allow the wood to move. You could even make 1/16”-1/8” reveals/gaps part of the design.

I think having gaps 0r reveals in a bartop, or any tabletop, would be problematic in regards to cleaning food debris and spills.

Perhaps. I have a split top dining table and it hasn’t presented any issues thus far. I saw a 50s Nakashima design and was inspired. I also have a 2 year old that is often making quite a mess. Cleaning and maintenance is just part of life, the way I see it.

PS welded up a temporary steel base as thats the material I had on hand. Hope to replace with a trestle base soon.

Agreed, veneer is really the only way to do what you want to do without causing the whole thing to self destruct due to wood movement. I would personally tend to shy away from a veneered bar, though, as I am not sure how long it would last. The thinner the veneer the better it will survive the stresses of wood movement but the worse it will fade against moisture and wear and tear. The thicker the veneer, the more durable it will be but the more susceptible it will be to self destructing wood movement.

A 1 1/2” - 2” thick solid top cut into an arc might not have gone sunburst effect you want but it would be far more durable, easier to build, probably much cheaper in the long run, and still very beautiful.

In my post I asked if it needed to be mounted onto a plywood. If it's doweled, glued with a no creep glue such as plastic resin glue or hot hide ( some would say titebond lll and maybe so) and can move with expansion ( and in your case to all points of the compass) I don't see why it wouldn't act as one piece.

Alan Peters did a series of half round scalloped top tables with tapers quite successfully. Yours is much larger but the principle is similar. His were a series of much narrower tapered pieces and I was thinking that that would help to eliminate the possibility of some piece deciding to cup. Does a edgeband help or hinder? Good question!

I think it's a grand ambitious project with lots of complications. One of the quiding principles of one off craftsmanship, I think, is the risk of failure.

I had pondered such a project in a table for a long time, and never got around to it out of these same concerns. But I was thinking that all the wood movement would be in a radial direction as the grain could all be in the same direction. That is, the outer edge would move a lot; the focal point, not much. Thus leaving the straight edge eventually not straight. Not true?

It feels like the movement would become almost radial, like why a log slice will pac-man split as it dries. With only half of the circle I would agree with Stan, the back edge would turn into a shallow curve. It might not be objectionable given the application.

How to fasten it down is an interesting question. If it were set on a plywood cabinet box, (not glued to it) some large holes and fender washers could allow for "off-line" movement. Sort of an elongated screw slot in all directions.

If you try to add an edge treatment it had better be flexible.

Excellent advice. These ideas helps immensely and will help us rethink our approach!

I'm with _MJ_ here.

I think it will hold together but movement will be radial - provided fixing takes account of this it will probably be fine.

I have considered if I would use veneer - it always has been used for this purpose for a good reason, but in context, the movement is likely to be small and the full thickness would be much easier to construct. Joining veneer is not without its own challenges.

The real issue will be the front edge. I just don't think that much end-grain will be attractive and there is no good way to wrap it if you use solid wood.

So:

If end grain is acceptable, and ease of construction appeals, then accepting the movement and using solid wood is your go-to.

If you don't mind a bit of fiddling and want a more robust result with a better finish then shop-sawn veneers are your friend. I would aim for 1.5 to 2mm - about 1/16" to 3/32" if you have a drum sander, or 1/8" if you don't.

As far as veneer goes then just get a high grade - like appleply and in quarter sawn white oak edgeband it and be done with it. Companies like Mt Storm will make any kind of plywood you want. It's not the same thing is it! Alan Peter's table is end grain exposed ,it's worth a look. I thought a similar thing..threaded inserts into the top and bolt it down to whatever with big round holes and big washers.

This forum post is now archived. Commenting has been disabled