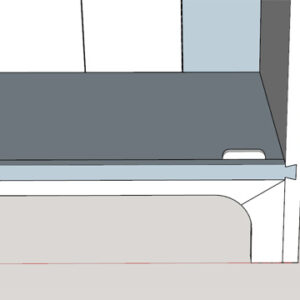

So I’m fussing with the bottom joinery on a chest of drawers while the wood acclimates in the garage. The base joinery is basically what Chris Becksvoort uses on some of his chest of drawers. The bottom panel connects to sides with a dovetail dado and is reinforced with glue blocks. See pics. Originally I planned to just use a cherry panel for the base, but started thinking maybe it would be wiser from a wear standpoint to use hard maple with say a 3/4 inch wide cherry face. The drawer side itself will be hard maple 8 3/4″ high. The maple panel for the base would be about ~20 inches wide. I calculated the difference in seasonal movement between the cherry side panel of the chest and the maple base panel to be about 1/8 of an inch front to back. That assumes a seasonal change in moisture content of the wood over any given year to be about 6% and using the movement factors for flat sawn from Lee Valley’s wood movement reference guide. Here’s the calcs.

Cherry: 20″ wide x 6% change in MC x .0025 = ~19/64″ seasonal movement

Hard Maple: 20″ wide x 6% change in MC x .0035 = ~27/64″ seasonal movement

Difference: 27/64″ – 19/64″ = 1/8″

I suppose I could glue only, say, the first six inches of the dovetail joint and use slotted screw holes on the glue blocks and not glue them or glue just one side, and finally cut the bottom or base panel width 1/8″ short in the back. Is that what you would do or is there a better way to deal with this?

Replies

When you say "from a wear standpoint" what wear do you mean? If you're talking about the drawer riding on the panel there are ways to take care of it without risking the integrity of the chest.

On the other hand, if the cherry sides are held to the maple base panel with unglued sliding dovetails you could use a glueblock at the front to hold the face registration and glue the rest of the support blocks to the cherry sides but not the maple base panel. (or do the screw / elongated hole thing) The movement diff will push to the rear of the case and be invisible to everyone you don't point it out to.

By wear, I meant the drawer riding on the panel. How would you deal with that? Would you stick with cherry for the base and cut a wide rabbet on the top edge and glue in a hard maple runner flush with the top of the panel keeping the grain direction the same or something like that?

Original pieces used pine for drawer sides, backs, and bottoms, and hardwood for runners. It's easy to fix wear on a drawer -- if it happens in your lifetime. Fixing a runner is harder.

I wonder if that extended the life of the runners or just shortened the life of the drawer sides. I've never seen an original shaker piece up close enough to know. The dresser I'm replacing is about 100 years old (family heirloom on my wife's side). The runners on the second drawer down and only the second drawer down are badly worn. The sides of the drawer don't have any noticeable wear are fine as is. I think the same wood was used for both, but not sure. It probably was the most used drawer in the dresser. I'm not getting rid of the dresser, just relocating it.

I totally agree with designing a piece so that the bottom of the drawer sides wear out first, if it lengthens the life of the runners. I have read and heard many times to use the same wood for both runner and drawer sides. Looking at this old dresser, it doesn't appear that approach preserves the runners.

Part of the problem is that the drawer sides are narrow, and can cut a groove in the runners. A better method is to use drawer slips to increase the bearing surface on the runners, reducing wear on both. But slips were used more in England than the US.

I'd say that pattern is normal. Top drawer; special keepsakes and favorite things, second drawer; socks and underwear. Bottom drawer; summer / winter swapouts.

Many options... First would be just choosing a wood for your drawer sides that's softer than cherry. If you went with poplar for the drawers the wear would be mostly to the drawers, not the case, and make for an easy fix 2 generations from now.

You could set in runners, or just rub a block of wax on the surfaces. The bottom drawer is the least used in most chests and will get the fewest opens anyway. I like to hang drawers on wooden runners or ball bearing full extension glides depending on the project.

Stay with the same wood for sides and base and use plastic tape like this for the runners. It works great.

https://www.amazon.com/WOD-Polyethylene-Transparent-Tape-Aggressive/dp/B07JFTYPWK/ref=sr_1_2?crid=2DWAFLHQ8L6EO&keywords=hdpe+tape&qid=1649805363&sprefix=hdpe+tape%2Caps%2C141&sr=8-2

According to your drawing, you have the back panel entrapping the bottom board from expansion. Unless you have a dado in the back panels to receive the movement. Secondly, you can use a harder wood like oak runner inlay or on top of the bottom board to make the spacing 1/16 for the front panels. That is what I have used on all of my drawers regardless of the side material, oak on oak when waxed they move very smoothly and will wear for a century. Best of building.

You're right. That would have to be dealt with, if I went that route.

If the bottom panel and the side panels are the same material (cherry) and the grain is running in a compatible direction (sides vertical, bottom horizontal) there will be no differential movement with both moving together. The back should be fastened to the top and bottom panels and all will move together entrapping nothing.

This is classic woodworker overthinking.

1. How long do you plan on having the chest last? 10 years? 20? 100? It is not going to last 800 so at some point it is going to wear out. There is no point designing furniture to last beyond its reasonable likely utility.

2. The difference in wear characteristics will not be significantly different between your choices - over many years the drawer sides and slides will wear out no matter what you do.

3. If durability matters then install ball bearing drawer slides - the fact that they were unavailable 100 years ago does not mean they should not be used today.

4. If you want traditional joinery and longevity then design for replacement of the wearing parts - put softer runners in place for the drawers to slide upon and allow a deeper well under the drawer base so that worn wood can be removed and replaced.

5. You have made a bit of an error in calculating your wood movement - the panel will move, but the frame will not, at least not lengthways, which is across the width of the panel. The difference is thus between the movement of the panel and zero, which is a mite more than you have calculated.

Don't bother with the glue blocks. They are utterly superfluous and the cause of your anxiety. If you simply use the dovetail dado, then you'll be fine. For ultimate class, just make the base a hair wider than it needs to be, and set the front and back into slots in the front and back frame. This will keep it flat and be neat, hiding any movement allowance. Fix the bottom panel in place with a single brad in the centre of the dovetail.

Even the dovetail is surplus to requirements. Make the frame strong and you won't need it - you can simply treat the base as a floating panel. Antique furniture will usually have the base board simply nailed to the frame or battens set inside the frame - the nails permit movement, or the board is just allowed to split - it's a hidden piece after all.

Thanks for all the good advice, everyone. Since as MJ pointed out the bottom drawer will likely get opened and closed the least, I'm going keep with a cherry panel on the bottom and use soft maple for all the drawer sides in the dresser. The upper drawer runners are hard maple.

On another note, are you using a secondary wood or is the entire bottom cherry?

I've often thought of gluing a strip of laminate to the runners.

Why not just do the carcase with dovetails? Those blocks seem like a cheese out to me - something a hack or factory would do.

The entire bottom is cherry. The sub top is cherry also and dovetailed into the sides. The design as is doesn't appear to lend itself to dovetails on the bottom. The sides extend beyond the bottom panel to the floor. This is a seven-drawer chest with split drawers on the top. The five drawer dividers in the front and the five in the back sit in stopped dovetailed dados on the sides. The back will be frame and panel to add a little more strength against racking. The original drawing showed lapped boards. I got lazy on redrawing that part. Just cheesy or not structurally sound enough for this piece?

“[Deleted]”

I think the case joinery as drawn is rock solid, I just question the need for the bottom blocks at all. That full-width dovetail should do the job by itself.

How are you handling the frame connections to the case in terms of the case movement? If you glue in the front and back stopped dovetails you may have an issue. Those frames are going to move very little with the case, if they move at all. Maybe glue in the front and float the back in over-deep dovetail sockets?

If you build it tight and glue up in Summer the frames might push the back out when the case shrinks in winter. If you build it tight and glue up in Winter the case might pull the frames apart when it expands in Summer.

I'm planning to glue only the first 6 inches and the last 6 inches of the bottom panel to eliminate any risk of it getting stuck when installing.

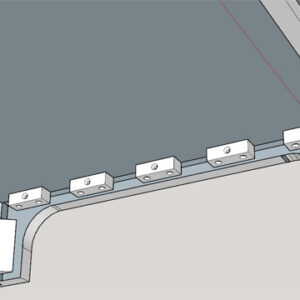

I'm still fusing a little with the frame to case connection. The side panels have an 1/8 dado and then a stepped dovetail dado on the ends. The runners are 14 1/2 inches long (18 inches if you include the tenons) and I'm leaving an 1/8 inch of play in the back mortise and tenon joint. I've been thinking about not gluing the runners or the back divider in place. I thought I'd maybe put one or two slotted screw holes in the runner and secure it in the dado on the side of the case that way. The stepped dovetail joints are short, only 3/4 inch. They will probably get extended. So yeah, glue in the front divider and everything else floats and is replaceable is what I'm thinking. A lot of this is the way Chris Becksvoort builds his dressers and I've adopted a lot of his method of work for this case.

You should glue the front and back dividers into the side stopped dovetails. This forms the structure of the case. The drawer runners should be mortised and tenon to the front and back dividers only left short enough to allow for movement. There is no need to fasten the runners to the sides in any way. Glue them to the front divider and let them float in the rear.

Nice, a lot more to those joints than what was visible in the last sketch. Put up photos of the finished one and the family pc when you're done, love to see them side by side.

Here's a side by side and one other. Although both are identical in size the actual one looks a little wider for some reason in the side by side.

Whenever you're dealing with "perspective" views, your images will be "distorted" to some degree. The only way to get a true side by side comparison is using true elevation views.

Very nice!

Nice!

“[Deleted]”

This forum post is now archived. Commenting has been disabled