Hi All,

I am looking for the very best wood patch product on the market.

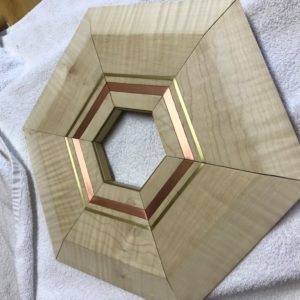

I am a reasonably advanced woodworker (45 years) and I am totally embarrassed that I am even asking this question. I made a hexagonal lid to a jewelry box and it is perfectly stunning except for one minor detail – the joints have gaps up to 1/32nd of an inch that looks like I can drive a MAC truck through, especially since the wood is maple. Probably due to run-out on my old crosscut saw.

I literally haven’t used wood patch in a couple decades and simply don’t know what to believe with what I read online.

It needs to blend well in color, and be flexible so it doesn’t crack. Otherwise this will be firewood.

Thoughts?

Replies

Ground unicorn horn, mixed to a paste consistency with jackalope tears.

There is no magic or invisible wood filler. If you are keeping a clear finish on this, you will never disguise the gaps.

Do you have a leftover piece of the top? If you do, take one section out, close the gaps on all the others, and cut the last piece to a custom fit.

Make a sled for the tablesaw and recut them all. The lid will get slightly smaller. What looks like brass and copper should be no issue for a fresh carbide blade.

I think your lid will have to become another piece of firewood.

If you re-cut the joints, and insert a 1/8" contrasting piece of wood, the lid, IMO, will look off - even if you use your router to continue the "inlay" down the box's sides.

If you do as John_C2 suggests - discard one section of the lid and custom fit the 6th piece of the lid - you run a serious risk of the lid only fitting the jewelry box in one orientation. And that's before you consider if the eye will see the lid as unbalanced.

Sorry I can't be more helpful.

You will not be able to hide these gaps. However, to my eye, they don't look that bad. The gaps are a fairly consistent width and, if you hadn't said something, I would have assumed they were intentional. Maybe you can figure a way to improve the consistency of the gaps and leave it so it is truly intentional. You could also paint a contrasting color into the improved gaps or, perhaps, inset some contrasting wood strips or repeat the metal look in the bands you already have. I think one of those or a similar solution would look good.

Fire wood you have, you will be pulling you hair out tying to fix this. Wood patch is not much better than it was 45 years ago. If you are great with putty, brush with colors you might hide it. It will crack open at the joints sometime due to wood movement. Best to make another.

Thank you all for your comments. Back to the drawing board.

Keep in mind that you can't just cut all of these angles on a saw and have them match up perfectly. If each gap is 1/32 of an inch, each angle is off by 1/6th of that. That's really, really small. To get that many angles exactly right off a table saw is miraculous. Holding a piece a little tighter or looser will change the angle, however slightly. It can be an exercise in frustration.

Fine tuning angles with a shooting board gives you a lot more control. You can finesse miters with much more accuracy than with a power tool.

If you can afford to loose up to 1/8 th per joint, you could use a disk or edge sander and fit the pieces together one by one to create two halves that then needs only to be jointed and assembled to form a complete hexagon.

This forum post is now archived. Commenting has been disabled