Hi, I have a bit of a conundrum…

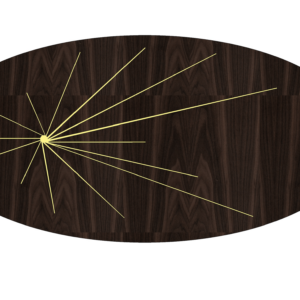

We designed a table for a client made of white oak with brass inlays (see pics). The table has been in the house for nearly 2 years now and the wood has buckled substantially where the grain runs perpendicular at the end of the brass. (I don’t have any pics of the buckling unfortunately, but it’s quite raised). We are going to need to repair the table, but are afraid this will happen again. We live in the San Fran Bay Area where humidity levels vary highly throughout the year.

the current brass is 1/4″ in width and depth. We were thinking if we filled the channel with a substance like silicone which had some give and then placed a thin layer of brass laminate on top that may work? The other thought was to remake the table using a high density MDF that wouldn’t move, and then placing an oak laminate on top and then channeling in the brass?

Any suggestions would be much appreciated. Thank you!

Replies

Very cool design.

I think you are probably on the right track with designing to allow some movement.

Even if you redo it with MDF/Veneer, I'd still be thinking about providing some kind of escape for the brass/wood if they start to move at different rates. I'd guess that using thinner brass will help mitigate the issue,much like using veneer mitigates some wood movement challenges.

Lovely table top there - unfortunate that happened!

I think you are on the right lines with thinking of using MDF/Veneer, but if it was me I would use Baltic Birch which should not move at all and have better structural integrity. Be certain to veneer cross grain and top and bottom to avoid cupping. Also, I would use thicker veneers - in the 1/16" range -which will make it easier to do the inlay without tear out of paper thin veneer. I recently sourced some thicker veneer from Certainlywood.com and was pleased with the quality of what I received.

Good luck - re-post with your fix!

How thick, that is, how deep does the brass go down into the wood? And of what is the top currently constructed?

Those questions were answered in the op.

You say that the buckling mostly occurs where the brass is perpendicular to grain. That is unfortunately almost everywhere. The oak boards are laid up perpendicular to the long length of the ellipse while long lengths of the brass exploding star mostly goes against the grain. I have to say it's a good looking table and I always take my hat off when someone does a good ellipse... however.. the whole thing is a problem with the design.. Partly is the choice of oak which expands and contracts with humidity more than most woods. I do like the effect of the boards going across the ellipse but had they gone the other way you would have had much less crossing of the grain and maybe with a tweek of the design of the brass inlay no crossing at all. You can't be completely sure that oak veneered over a more stable substrait won't end up with a similar result. The wood expands and comes into contact with an unmovable or compressible object..it has to go somewhere, so it goes up. I'm surprised that the wood didn't shrink back and leave ugaps along the brass strips. Also, then it's veneer over mdf , edge banding and it's Wayfair! One of the true marks of craftsmanship, I think, is the risk we take of failure. We go out on a limb and design something with an original idea and we take a risk. You say it's 2 years old and the SF bay area has big swings in humidity. That is true ,but the bay area has had probably the least amount of swing in humidity over the last two years than maybe ever. Hopefully that will change, better for the plants and the people but actually worse for your table!

By the way that brass will expand and contract alot if that table is in a sunny spot.

This may sound like heresy: Find a shop with a wide-belt sander and run the whole top through. Get the surface flat again and see what happens before rebuilding the whole thing. The brass should sand just fine.

“[Deleted]”

Would you consider replacing the brass strips with casting resin or epoxy mixed with brass pigment powder ?

a good idea. we actually considered that, but think it may cheapen the look of the table, it's a $12K piece so we'd like to keep the brass in tact if possible...

No experience, so please take this as speculative.

1. That is an awesome piece of work. Beautiful design and execution. I love the legs too.

2. I'm with @_MJ_ as usual. If you think about it, expansion and contaction around the brass may not be the cause of the problem here - the wood should be able to move well enough and the brass should not prevent this.

Could it be that the wood has simply expanded upwards a little? It may well stay in that position so there is much to be said for the sand it and see.

3. I disagree with those saying the MDF will not work - that is the most certain option. It will provide the best outcome and is pretty much guaranteed to work.

You have nothing to lose from the sanding option. Even if you re-make the table for your client, you will still have the old top to use for a new piece and if the sanding works you can make another table and sell it to recover some of the losses.

Thanks Rob! The client thinks the table has actually stopped moving now (we went over there yesterday), so we are going to try re-sanding and finishing and cross our fingers!

Please come back and let us know how it turns out.

This forum post is now archived. Commenting has been disabled