Cabinet Saw Shopping, need help.

Hi Everyone,

It’s been 9 years since my high school cabinet/construction class, the highlight of my schooling. I want to get back into woodworking, so I’m at the point now where i am financially equipped to set up shop and have lots of time to refresh and hone some skills.

I’ve got a list of equipment in interested in purchasing. But the table saw is the one I’m having the most difficulty with.

like so many people i cannot run a 220V table saw. I’m renting a small cabin right now without a basement or workspace. so ill be setting up shop in my 120sq enclosed trailer. this is all i have to work with but i know i can make it happen with some smart organization and movable equipment it will be small but its better then nothing. I’m thinking that sometime in the future ill be able to rent a larger shop or build my own so that brings me to my question… (thanks for sticking with me)

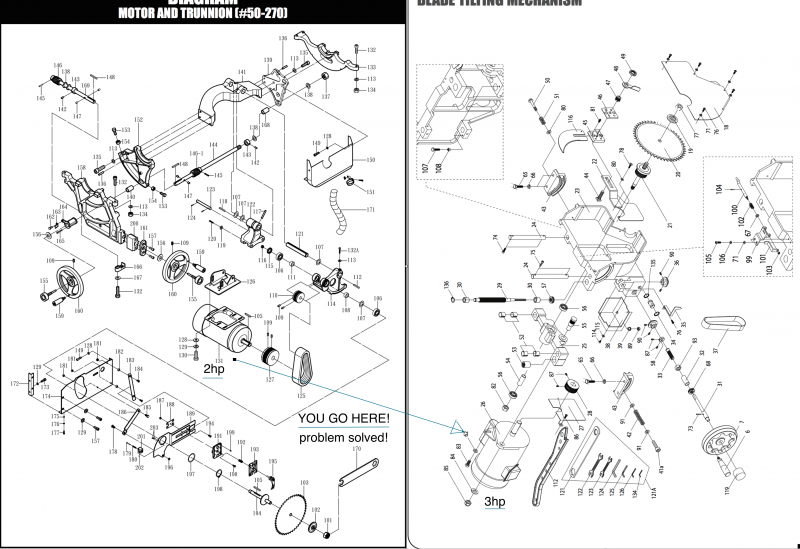

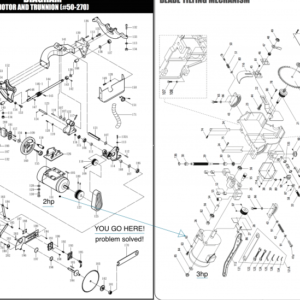

Are there any tablesaw manufactures that make a saw that can have the 2hp (120V) motor swapped out with a larger 3hp motor? or vice versa. I’m just trying to think of the long run, i want a saw that will last a lifetime, just one saw. i don’t see the point of buying a hybrid saw only to have to buy a entirely new cabinet saw when i want to upgrade just the motor. id be open to the idea of buying a 3hp cabinet saw and putting in a 120V motor for now.

Has anyone seen this option available? or done something similar? I’m worried that if i “rig” something up ill end up not having things lined up correctly and get vibrations.

i should also mention I’m in Canada. but please don’t leave out any american manufactures.

I’ve looked at the spec sheets for some saws (general int., grizzly) but find that the 2hp motors seem to always have different mounting brackets then that 3hp.

Thanks,

Jacob

Replies

Buy Used

I purchased a lightly used but old unisaw in 1980. It has the cast iron base and the older 1-1/2 HP "bullet" motor. It has beed used hard in my millwork shop the first 15 years, since then I have downsized, but it is still going strong in my one man shop. I have had the motor rewound once or twice and replaced the arbor bearings once.

I would recomment you buy an old delta, Powermatic, or maybe General saw, American or Canadian made, not the Asian made stuff they sell nowadays. The unisaw is hard to beat and there are still plenty of them floating around. They are smooth as silk and will last a lifetime and then some.

Horsepower: I could never upgrade my motor because of the design so I was stuck with 1-1/2 HP. With the exception of heavy ripping on a production scale it is more than adequate. I could still rip a cutlist of 8/4 hard or softwood, but just not as fast as I would have liked. Although I do not recomment thin kerf blades, I make an exeption for rip blades on a light HP saw, will make a big difference. A 1-1/2 to 2 HP unisaw with the later Baldor style motor should more than meet your needs, and can be upgraded with up to 5hp 3 phase in the future with no modification if I'm not mistaken.

The original 24" Jet lock fence is not too bad a design and will fit your small shop. You can upgrade the fence to a Biesmeyer style later.

It is tempting to buy the shiny new toy and even the Asian built Deltas are probably not to bad, but you will get much more value buying old American cast iron.

In any event, I would consider a Unisaw "style" saw a bare minimun, any less and you will be disapointed if you are serious about your work.

Good Luck

Rob

Thanks, I've been hearing alot of good things about the delta unisaw. and i think your right a 1 1/2Hp motor that can rip 8/4 hardwood should be fine with what i have planed. i guess its a matter of cutting a bit slower and making keeping shap blades on hand if things seem tough. i'll be geting a router table too, if i need to dado ill probaly use that. and i was planning on riping venners on the band saw. ill keep an eye out for the deltas especily the ones with baldor motors.

Thanks so much!

Dadoing on the saw will not be a problem at all. It is not nearly as challenging HP wise as heavy ripping.

Rob

Obviously our knee-jerk response is to get the best and best suited machine you can. This is good advice but, the best suited machine that will be put into and removed from a trailer changes the picture. A tablesaw that you will try to use inside a 120 sq ft trailer also changes that picture.

If you will be doing a lot of sheetgood, kitchen and bath-type builds I would lean toward a guided circular saw. The number one and number two in several bake-offs are at opposite ends of the price spectrum. The Festool products are often number one with the Makita offering coming in at number two.

In that small foot print I would use a router for all my rabbeting and dado work and possibly keep a small job-site tablesaw for some tasks. This comes from a position of trying to pick the best tools for the job where my go-to tool just doesn't make sense (to me).

As for trying to find a tablesaw that you can upgrade by swapping motors, I would not go this way. For where you are in your journey, I would pick up a used job-site or contractor saw for $100 to $200 and consider it disposable once your situation changes. Again, the track saw would do most of your panel cutting tasks.

I am not usually this long-winded ;-) If you are going to be doing hardwood furniture and cannot house/operate a large tablesaw (remember, it isn't just the machine, it's operating it that takes up the room), hand tools will be your friend. Of course to use hand tools comfortably and effectively you want a good bench but, that's another thread.

Let's see how this thread develops before I talk you to death.

Having a "real" table saw in that small a space won't leave much room for actual work. I think that long-winded GeeDub has some good interim solutions for the point in time when you have space for that size saw. Circular saws take up almost no space, and the space you do have can be used for a nice little workbench with an end and tail vice. With a nice bench and a circular saw on a track or home-made guide, you could do sheet work pretty darn accurately.

A circular saw is great for crosscuting and a nice bandsaw would work well for ripping - and in many cases is the preferred route for longer hardwood boards. A bandsaw's footprint is quite small, although you still have the infeed/outfeed space you'd need for a table saw.

For the space, I would go with a track saw, get to building, figure out what you want to build and get your “last” table saw later when you have a bigger shop sized for big iron. Had I known more about track saws when I got back into the hobby I would have started that way. As mentioned above, track saw, bandsaw, router, (lunch box planer and bench top jointer maybe as well depending on what your building, maybe a chop saw too) and you have a very well equipped shop. I’ve seen the reviews and if budget isn’t a limiter the Festool wth their MFT saw table and all its available accessories is an amazing system. I have a Dewalt and am very pleased with it - no complaints. I got the 102 inch track, the 52 inch track and a set of track clamps. It’s a great way to cut plywood directly to precise size, but can cut anything a table saw can. The track is zero clearance so no tear out - table saw quality cuts. And it has a riving knife - very safe. I haven’t used it but the new Kreg Track Saw with their table is intriguing. A track saw costs much more than a circ saw. I think with a circ saw you will likely wish you had a table saw.....with the track saw and a bandsaw, not nearly as much. And, you will still have it to break down sheet goods when you settle into your new shop. Best wishes as you start back into woodworking!

I have a shop that is not much bigger than your trailer. You are going to have to move your saw outside to RIP anything of length. This means jobsite or contractor saw is what you need.

Thanks for giving me an opportunity to go down memory lane. My first shop was a 10x10 back bedroom in a mobile home we put on my wife's grandparents' land. That was 40+ years ago.

Rather than looking for a 'forever saw,' you might consider getting (if your budget allows) a higher-end jobsite saw to begin with. I noticed that a couple of woodworking stores are selling the SawStop jobsite saw for $999. One of these should hold much of its value when you want to sell it and get your next saw. With your shop situation I doubt you'll want a saw that you can't move around easily until you get more settled.

You also need to consider if the floor joists of the trailer will handle a heavy saw.

I've bought seven table saws and sold six in the past 40 years. While I'm glad that I finally could afford a good cabinet saw, all of the saws I've had--mostly Craftsman and Delta contractor saws--brought me no end of pleasure.

I don't own a table saw. Depending on how much work you are doing, I am quite content using a handsaw to cut things. It doesn't make much time to get really good at it.

I can draw two parallel lines that are a 1/16" apart and stay within those lines all day long while sawing rip or cross cut. I am nothing special and my first few cuts look like a drunken beaver did the work but fairly quickly I got the hang of it.

It might get you through until you move somewhere a bit bigger.

This forum post is now archived. Commenting has been disabled