Cannot Align Splitter on Delta 34-444

I just got a Delta 34-444 table saw for $100. It is in good shape.

I am trying to tune it up before I use it. I have checked the blade alignment, it’s good. I have adjusted the fence with the miter slots, good.

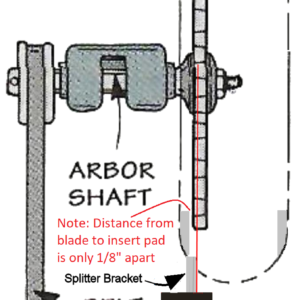

When I got to aligning the splitter to the blade, I ran into a problem. The alignment is not correct, but I cannot seem to be able to adjust it. I loosened the splitter bracket (it is attached to the rear trunion). The closest I can get is about 3/16″ I have included a drawing, not to scale, to attempt to show the problem.

One more, thing. The blade is only about 3/32″ from the pad for the insert. Is this correct?

Replies

It sounds like someone did what I always do on contractor saws, move the trunnions as far to one side as you can to maximize the opening for changing blades. 3/32" is pretty close but, I have zero clearance inserts that run a lot closer.

The splitter bracket should move with the trunnions during alignment and this sounds like how this design works; "the splitter bracket (it is attached to the rear trunion)".

I will try to find a manual for your saw to see if I can get any ideas.

OK, pagers 10 and 11 of the manual linked from this page give me a pretty good picture:

http://vintagemachinery.org/pubs/detail.aspx?id=5392

The initial alignment of the bracket with the inner washer of the arbor is what needs to happen. The rest of the parts are made to assemble once that is done. If you cannot get that bracket to move to that position I would confirm that there is nothing blocking it. Sawdust buildup and oil can cake into a pretty imoveable sludge.

If nothing is in the way I would consider filing out the holes to allow more movement if there is adequate material on the bracket to allow this.

Please check that out and let us know what you find.

I have had that saw for over 30 yrs. My best advice is to scrap the splitter and go to Sharkguard. He can set you up with more advanced manual riving knife and other great safety stuff.

Thanks for the manual pages you attached, the pics are great.

I did check for obstructions, did not find any.

I took some pics showing the situation. If you would like a better view, let me know what angles you might need. Pic 01 shows the actual misalignment with the splitter off. Pic 01c is a more open view with the blade off. Note that the splitter bracket is as far right as it can go.

To galturner, thanks for your input. I was thinking along those lines, but the sharkguard is too pricey for me. Maybe a zero clearance insert with a thin splitter at the end of it?

Something funny going on around here. I do not see how that bracket could move any more. The odd thing is how did the relationship get so distant in the first place?

The blade is flat against the arbor without any additional spacers or washers, yes?

P.s. A Sharkguard mounts to the original bracket in many cases so the problem needs to get worked out either way.

The blade has no additional spacers or washers on the inside. The only spacer (washer?) and nut are on the outside of the blade away from the arbor.

I have not used the saw yet. Maybe the previous user moved something? The splitter and guard were not attached when I got the saw. Also the saw did not come with a table saw insert.

Could the arbor have been installed improperly? Looking at the pics it seems as if the the arbor is angled to the right.

Will the table top come off by itself or is all the mechanism attached to it?

Sorry, still here... I am still trying to figure out the problem with my saw.

I just took a picture of the back of the saw. Maybe this can clarify what the problem might be... I am not familiar with the mechanics of this saw.

Are the trunnion guide bars supposed to be angled like that?

Bingo. Those bracket rods should be parallel to each other and even with Mother Earth. I think we have found your alignment problem.

The direction that the splitter bracket needs to move will be your tip off as to whether the left rod is high or the right rod is low. If it is bent at a specific spot you may be able to slip a piece of pipe over the rid and lift or press it back into position.

Don't kill yourself over getting it perfect. Anything is going to be an improvement over that tilted assembly. Notice how the motors in the pics are parallel with the floor.

P.s. "Will the table top come off by itself or is all the mechanism attached to it?"

The trunnions (arbor lift/tilt mechanism, etc) is attached to the top in a contractor format saw.

no, it should be straight across, not angled. It seems that would be your problem. That saw took some abuse to twist that. I will reiterate on my comment on the sharkguard. Once you get the original splitter on, you will find it is floppy, and will not stay in position. Your rips will jam up etc. I threw mine away on the first day I had it in the 1980's and used it without anything for 30 yrs until I found sharkguard, and it's manual riving knife.

Thanks for your input GeeDeeBee and galturner, I really appreciate your help.

I found some sites that address the problem...

1. https://www.popularwoodworking.com/techniques/accurize-your-tablesaw/#unique-identifier

2. https://www.youtube.com/watch?v=XXY_i-KWdYI

3. https://groups.google.com/g/rec.woodworking/c/FSp01UhaJFk

I tried the 2nd site (youtube) and it worked! I used a 1/4" steel plate that I had laying around and followed the instructions. I measured the alignment of the splitter and it seems to be aligned. Now I will go over the whole procedure again to make sure the tablesaw is aligned.

I can't wait to start using my $100 dollar saw! First on my list are a few jigs to make the saw more safe and accurate and also to gain experience on the proper and safe way to use the saw.

The saw came with a well used Biesemeyer fence, but no rails, future project?

Well done! My hybrid had a Bies Commercial Fence. They lack the bells and whistles of newer designs when it comes to setup but, once setup they are pretty bullet proof. I loved that fence. I see folks selling rails here and there. Probably those who moved to an Incra Positioner or similar setup.

This forum post is now archived. Commenting has been disabled