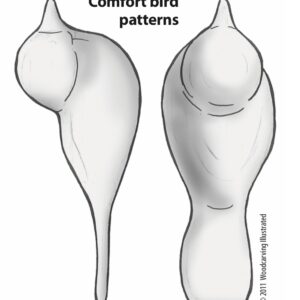

I have a question for you all. I plan on making some “comfort birds.” They are small wooden birds cut from a piece of wood (2x2x4 1/4 inches). They are made without many details, soft and smooth.

They are often cut from wood using a band saw, sanded, and then varnished. I’d like to be able to use all kinds of wood for them, from soft woods to hard woods.

Also, for this project, instead of any hand saws, I’d like to use power tools.

I’ve attached a photo of the pattern below.

1) Do you think that a jigsaw or a scroll saw could be used instead of a band saw?

2) What kind of saw do you recommend and what model?

Thank you in advance for your kindness in answering my questions!

Replies

That pattern said woodcarving illustrated in small print. If you have a pattern with a profile instead of like those shown you could saw it out of 3/4 inch stock either with a bow saw (thin blade for making tight turns), a coping saw, a jig saw, or a band saw. I don't have the electric saws and would have to go with the hand saws. Once you have the profile cut out, then it would be ready for carving.

Thank you for your reply! For now, for this project, I’d really like to use all power tools. (I’ll update my post to be more clear about that.) I’m saving your excellent suggestion, though, for future hand carving.

For small work like this a bandsaw would produce the least chance of breakage. The reciprocating blades of the other options will be jumpy on irregular parts.

Plan your cuts so you can use the cutoffs as cradles for subsequent cuts. You can use masking tape to reassemble your block between cuts. Cutting the tails overlong will provide handles for working safer.

Thank you for your good ideas! Today Rockler recommended that I use a Dewalt scrollsaw (DW788) for the project. Is there a bandsaw that you recommend? I’ve read good things about the Wen 3962.

Not really my ideas, just passing them on... Pick a saw based on your maximum possible use so you don't have to upgrade. Mine is 220V 3 HP with about a 15" resaw capacity, but it could also cut your little birds.

Scroll saws have the least resale value of any power tool it seems

and Craigslist is usually full of them. People buy them and never use them. They are like exercise equipment. I like the RBI hawk. If this is all your planning on doing you could find a cheap used Wen or Dremel.

Thanks! I’m new to woodworking, and I didn’t know that about scroll saws.

The best quality 10” bandsaw would be the right tool to ‘carve’ out the birds if you wish to stay in the small bench top range of power tools. A jigsaw would not work at all and a scroll saw is primarily designed for fret work.

Maneuvering small pieces free-hand around a bandsaw blade takes practice. I would insert a sacrificial dowel handle in the bottom of the blanks to help stabilize the work.

Thanks! I’ll give that a try.

Hi Jeannie,

If I were cutting curves in 2 inch thick hardwood, I'd skip the scroll saw and go straight to a small bandsaw. Which small bandsaw? That depends.

A nine inch bandsaw is the least expensive and (with the right blade) will certainly work for this project. If you plan on putting the machine on the shelf afterwards, it may be the right choice. As I have no experience with 9 inch bandsaws I will let others recommend a good one.

If you want to invest in a more expensive and more capable small bandsaw then I recommend the 10 inch RIKON bandsaws. I owned the model 10-305 for years and it worked great. When Rikon began offering the 10-3061 that has a bit more power, a better fence and more bells and whistles, I upgraded. Both models are good machines.

Choosing the proper blade is important.

Determine the smallest radius you'll be cutting and refer to the attached chart. A 1/4 inch blade is good for general work if it's compatible with the curves you'll be cutting. As for number of teeth per inch - I'd go with 6 TPI.

Mike

I agree on not buying a scrollsaw. It's a lot to ask if you'll be using 2 inch hardwoods. A bandsaw is a better choice.

If you go with a small 9 or 10 inch model, carefully check the reviews. Most of the cheap ones, like Delta and Ryobi, are horrible, and you will struggle.

Thank you for your reply! I think that I’ll go ahead and purchase a small bandsaw.

“[Deleted]”

Thanks, Mike! After reading your message, I read several reviews of the Rikon 10-3061, and it sounds like an excellent choice. Do you think it has the power to be mainly cutting 2 inch hard wood?

Hi Jeannie,

Here is a video link of me cutting a piece of Red Maple on my Rikon 10 inch bandsaw. The maple is 2.75 inches thick and it has no trouble cutting curves in it. I'm using a 1/4 inch blade with 6 teeth per inch.

https://flic.kr/p/2mopo6J

Mike

I really appreciate you sending the video, Mike! A helpful person from Peachtree Woodworking recommended using a Carter stabilizer to add to the Rikon 10-3061 to help with the tight corners.

https://www.ptreeusa.com/bandsaw_upgrades_stabalizer.html

Do you think that would be helpful?

I have never found a need for the Carter Stabilizer in my work.

I switch to a narrow 3/16 inch blade when there is a need to cut super tight curves. It will cut all the way down to a 5/16 inch radius.

And my Rikon 10 inch bandsaw will track a 3/16 inch blade just fine with no drama without the need for a Stabilizer.

That said, Carter is known for quality products and if I ever have a need to use a tiny 1/8 inch blade, I would consider it.

Mike

The full power-tool setup for this is a small band saw and a rotary tool (dremel or similar) with saburrtooth shaping tools. You will need to do some hand sanding afterwards.

Whether you buy a large or a small band saw is going to depend on space and future use plans. You can cut those birds on a big saw with a fine blade, but it will be more comfortable to batch out large amounts on a small saw, and a small saw with a fine blade will always find uses. I recently had a job that required changing often between large and small blades and it would have been really good to have a small saw with a fine blade so I could leave the big blade on the big saw.

Most fine blade work is done on small pieces of timber so you don't need a grunty saw or a big throat. Big saws are also a bit 'hefty' for the finest blades. A saw that can tension a 1" blade will easily snap a 1/8" blade - you can of course make it work, but it's a bit harder.

So my advice is "buy a little saw and put a decent blade on it" - the blades sold with small saws are generally intended to become landfill. They are 'blade-shaped objects' rather than really useful tools.

If, however, you are interested in doing bigger stuff later AND have limited space or funds then it makes more sense to buy a 14" band saw with at least a 1.5HP motor as that will handle almost any work but still be reasonably useful for fine work.

Thanks for all of the great information! I’m new to woodworking, and I really appreciate the advice. I think that I’m going to go ahead and purchase a small bandsaw for the project. (My focus is more about high quality and ease of use and less about cost.) Do you have any recommendations?

What you can get will depend on your place of residence.

There are very few manufacturers of band saws in the low end of the market - anything below professional stuff is usually made the same way, if not by the same factory. They all have cheap components and are intended for light intermittent use so picking one brand over another is tough.

I recommend looking for a 9 or 10 inch saw second hand. With all the guides and bearings pulled away from the blade it should run without any wobble or scraping noises. That being the case, it's probably going to do what you want. The guide bearings or blocks are usually easy to replace and you can buy way better ones cheaply from engineering suppliers (go for decent Japanese made sealed bearings - I find they come in about NZD 10 (approx USD 7) each.

New is not expensive though - https://www.machineryhouse.co.nz/W950 is a decent saw and on sale for NZD558 (they are on sale more often than not, so this is the real price) You can see the same saw badged as Ascent tools in NZ.

If you want something a little different, consider the Rikon 10-305 https://www.rikontools.com/product/10-305 but this is more expensive yet lower powered.

The cheaper the tool, the more effort you will have to put in to tuning it up - I replaced all the guide bearings and had to spend an hour getting the fence square to the table on my Ascent machine - the Rikon probably comes ready out of the box. You pay a lot for that better fit and finish.

In the end, there is no difference between the cuts made by a cheap or expensive band saw - it all comes down to a sharp blade, good technique and good setup.

What you gain with higher priced products is a more robust machine, usually better 'out of the box' and greater capacity to handle larger cuts, but that is not what you want, is it? If you need to cut 10" veneers off solid oak then no small saw is going to handle that...

I appreciate the advice! You mentioned Rikon. I’m leaning towards the Rikon 10-3061 to start. What do you think about that one?

A common recurring theme in woodworking is the quick outgrowing of cheap and/or small tools. If your budget and space allows, I would strongly consider a good 14" bandsaw. This would put you in realm of most bandsaw owners and if you buy from a good company, you'll get good service and support.

You'll be able to tackle almost any present or future project with a 14" bandsaw, but you'll quickly get tripped up by the limitations of the smaller versions.

I can personally attest that Grizzly quality control has suffered lately, so I would not recommend them for any entry level power tool.

I once owned a 9 inch Delta. It was only 100 bucks or so, but it was 100 bucks completely wasted.

I bought a Ridgid 14 inch clone for 350 bucks or so. A clone, same as most 14 inchers. I spent more money on a riser block and other parts. The saw is totally incapable of of resawing decently. I still use the saw with a 3/16 blade for smaller curved work, without the riser block. Mostly, I use it to cut up longer scrap for disposal.

I bought a Laguna 14/12 for about 1,000 bucks several years ago. It can resaw perfect 1/8 slabs from 10 inch cherry, like butter. If I had bought this in the first place, I would have saved all that money on the Delta and Ridgid.

Also bought the Laguna 14/12 around three years ago. Wish I had skipped right to it as well !

The Laguna 14/12 looks like an excellent bandsaw! I only have room for a 10 in to start out, but I’ve read so many good reviews about the Laguna 14/12. I’ll remember it for down the road.

Starting with a 14 in makes a lot of sense! Currently I only have room for a 10 in, though. I’m leaning towards the Rikon 10-3061.

When I buy a bandsaw someday, it will probably be a 14" Laguna. Rikon has a 10 inch bandsaw that costs a lot less but can do quite a lot from what I've read. Highland Woodworking sells them along with good band saw blades from what I've read in this forum.

Thanks! And that’s good to know about Highland Woodworking. I’ve been hearing really good things about them.

Bandsaw is the way to go! Scroll saws have difficulty with 2” thick wood, many don’t have the clearance.

Sandpaper from Klingspor Woodworking Shop is my favorite as their main store isn’t far from me. I buy their cutoffs.

Don’t forget the drum sander. If you already have a drill press, you can find some to fit.

I don’t use the Poly as Mr. Faust did, I personally don’t like the feel. I use an oil/beeswax combo. I use flax seed oil or food safe mineral oil as I use it for treenware.

Jeannie, I carved a couple of the now deceased Frank Foust’s comfort birds back before my last brain surgery in December. I did them all by hand and think your on the right train for power tools. Don’t forget his use of a drum sander in the article. If you have a drill press, you can purchase the drums at minimal cost. Don’t forget to use tape to keep the blank together so you can cut the other plane. My favorite sandpaper comes from Klingspor Woodworking Shop, they have a large bargain bin at their store back by the bathrooms at their Hickory location. I prefer the gold and keep it in many different grits. But understand the color doesn’t make a difference. The pieces are run offs from their cutting process, I’m not sure you can order them from their stores, a call wouldn’t hurt to ask. I’m not sure all their stores have one as the plant where they process is also in Hickory. I live really close to it so it’s not an issue to stop by and see which grit is available.

Humidity is sandpaper’s worse friend as the abrasive can separate from the paper. One of the guys that work there suggested to keep it in some type of “air proof” container. I roll them tight, tape them together and write the grit on the tape. I can get some pretty wide cut offs that work on my palm sander. And I can use rip them easily by hand once it’s started for thin strips for detail sanding, though the stuff is tough as nails. I use an old Playmate and a plastic storage container, but if I ever get my shop built, I’ll use the old wine cooler that quit working

I also don’t use polyurethane, I personally don’t like the feel of it. I use an oil/beeswax that I mix myself. Currently I’m using flax seed oil but have used mineral oil. I keep it for treenware carvings. Beeswax is less expensive if you can find a beekeeper who sells it. After it’s dried a bit, I polish with a piece of an old cotton shirt. It comes to a high luster and I think of the hand oils that will polish it even more if the recipient handles it a lot.

Good luck!

I really appreciate you sharing your experience with making comfort birds! You carved some in December before your last surgery. I’m thankful that you’re alright, and I appreciate you taking the time to share your thoughts.

Your use of beeswax and mineral oil sounds perfect, and I’ll add that to the birds that I make too. And thank you for your Klingspor recommendation. I ordered some today!

When I combine Frank Foust’s method of making comfort birds, along with all of the excellent advice that I’ve learned from you and from everyone else in the forum, it seems like the project has 15 steps:

1. Trace the template onto the wood.

2. Using a bandsaw, cut the top view.

3. Tape the waste in place.

4. Rotate 90 degrees.

5. Cut the side view.

6. Rough shape the bird with a 1 1/2 inch sanding drum on a Dremel using 60 grit sandpaper. *

7. Shape the neck with a 1 inch sanding drum on a Dremel.

8. Use a carving knife to shape the beak.

9. Use the Dremel to smooth.

10. Sand the bird by hand with 150 grit sandpaper.

11. Buff the bird with synthetic steel wool until the bird is completely smooth.

12. Place a darning needle in the bottom of the bird to give something to hold.

13. Coat the bird with a layer of oil/beeswax mix.

14. Allow the coat to dry.

15. Polish to a high luster with a soft cloth.

*I mention a Dremel because I don’t have a drill press, but I do have a Dremel.

Do you or anyone else see any other steps? Is there anything important that I’ve missed?

Thank you again for your help!

This forum post is now archived. Commenting has been disabled