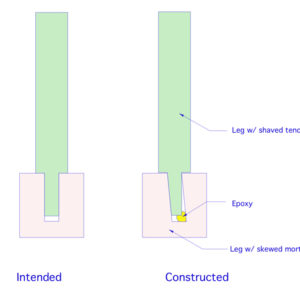

Learning to chop mortises I thought I had it down with the first trial chair. Then I tried a second in white oak and when I went to put the rails into the legs discovered I had chopped the mortises at a slight angle to the surface. My simple, if not great solution to fit the pieces was to bevel the face of the tenon.

I’m sure I’m not the first to have done this. My question is would adding something like a bead of epoxy at the base help fill the mortise and make the joint better or is there some other time honored method.

These chairs are for my amusement. The picture is to get show the problem without words.

Peter

Replies

You could square up the mortise and then thicken the tenon as needed with glued on pieces of veneer.

One of those deals.

You study the joinery on scrap for zero error on the project stock. Not for repair and an irreversible mess. Compromises look like hell. Shortening the rails, if tolerated, can buy you a new tenon shoulder face but the deal here is to ace this out before you cut project stock.

I do cut spares so if there is an equipment failure (or skill issue) I have backup stock. Just like the stink product: Carbonite.

In my opinion this is a do over, or widening the mortise and tenon as explained above. Chasing an error is not the way to go and usually results in more time wasted than if you had done it over. In addition, I am afraind that if this is for a chair, the tenon will distribute the weight un evenly and eventually the joint will fail.

Accommodating the less than perfect

The quality of a man, the superintendent on a job I worked with said, isn't finding or making errors, but figuring out how to fix them. The answers given to me here are useful and correct but also have a tinge "there is only one way to do things and it is to be perfect." I'm human. I make mistakes. Fuming over my failing in the basement I found myself thinking some of you guys would probably advocate throwing out the baby if it came out wrong. Do overs, sometimes are just not an answer.

On the third chair I still had the problem Again I shaved the tenon to fit the angle of the mortise but this time glued a piece on the opposite face and planed it to match the angle of the shaved face. On the second chair I tried the epoxy. If it breaks, it breaks.

But I bet there are many time honored fixes. It can't have been that uncommon an error. And thanks for encouraging me to move beyond that wry standard of approximate perfection.

Peter

"Again I shaved the tenon to

"Again I shaved the tenon to fit the angle of the mortise but this time glued a piece on the opposite face and planed it to match the angle of the shaved face"

You are on the right track with your solution.

I would suspect that many of the readers of this forum have, at one time or another, glued wood to the face of a tennon to correct a less than perfect fit. I am a little surprised at the many "do over" replys.

This forum post is now archived. Commenting has been disabled