Hello,

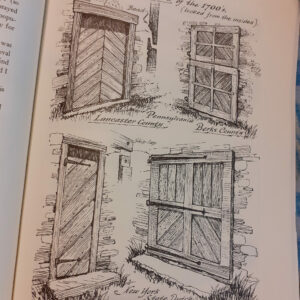

So I was asked to create an exterior door & jam replacement for an old pioneer log cabin. I thought it would be nice to design something that looked as if could have been made by a pioneer and original to the cabin but with modern functionality, and drew some inspiration from this book that described some early American door styles (see attached photo of book page). I decided to create it using some reclaimed barnwood to help achieve that old look.

The door developed a crazy warp in the top corner recently, like to a degree I’ve never really seen wood do before. I’m a little dumbfounded and wanted to see if anyone here with some experience in door construction can help give me an idea of understanding on what I may have done wrong. I’m a pretty experienced woodworker, but this was my first time trying to create an exterior door. I did a fair amount of research beforehand to see what types of glues are best, etc.

So here’s some more information about the construction and circumstances for reference. The outer frame is reclaimed oak and the diagonal boards were of an unknown species but also reclaimed barnwood. All wood I selected was pretty flat, straight, no cupping for as far reclaimed wood goes. The outer oak frame was connected with half lap joints, glued and clamped. I gave all the diagonal boards shiplap joints, also glued, and then diagonal boards were connected to the outer frame with glue and finish screws. I filled little knotholes and checks in the wood with epoxy to make a solid barrier. I used tightbond III exterior glue for all the glued joints. There are some decorative metal straps on the outside for effect. The jam and trim is also reclaimed oak and half lapped those trim corners as well with some 1″ dowel pins in the corners.

The door does face south and gets a good amount of sun in the winter, but gets more shady in summer when the trees have leaves. Now the door did develop a slight warp in that same corner, but inward not long after installing towards wintertime. I adjusted the door stop and took care of the problem. They didn’t have further problems with the door until recently (or at least what they told me) when the cabin got flooded with about a foot or two of water. You can make out the dirty high water mark in the photos. I would think that may cause the bottom of the door to warp, but don’t understand why the top would. Not sure it was caused by the flood. The cabin does have heat and A/C, but still seemed rather humid and hotter or colder inside compared to a normal home would be kept at. The door jam and trim all seem to be fine and unaffected.

Any thoughts on the matter would be appreciated. I think I may replace it with some kind of custom fiberglass door or something that could maybe recreated an early American look, but be more suited to an occasional flood and getting wet. Any recommendations there would also be appreciated. Thank you for reading!

Replies

I will speculate here that your problem is two-fold and my impression is the design was doomed to fail.

First you have wide boards of an unknown species and movement characteristics rigidly attached to a relatively thin frame without any allowance for wood movement. This effect can be validated by the warping in two directions. When the interior boards shrunk it bend the frame in when the expanded they bent it out.

Couple this with an extremely challenging environment and the door never stood a chance, no matter how attractive it is. With differing temperature and humidity on either side of those wide boards not to mention sun exposure I don't see how the door can be saved, but it was a nice look.

Thank you for the explanation. I guess I would wonder how they would have pulled off that kind of design back in the day, but guess I didn't consider back then, and also more of a barn door design, they wouldn't have had as hard of environmental differences between the indoor and outdoor sides. Maybe they made sure it was on sides of the barn that didn't get as much sunlight as well.

I have been thinking about this problem, I love the look of the door, but don't know what extent you are willing to go to try and save it.

If you could get the door apart you could build the door inside a black steel U-channel frame. The outer frame could be glued and assembled then screwed to the steel frame. Since you are placing the screws in long grain wood movement is not an issue.

The interior boards can either be ship lapped again with a deep 1" lap but leave a ¼" gap for movement these would not be glued but bonded with silicone to allow for movement. These boards also will be bonded to the exterior frame with silicone to provide a flexible bond while sealing out drafts. These boards would be screwed to the inside of the steel channel with a single screw in the center of the board to spread movement evenly on both sides of the screw. Make sure this screw does not enter the exterior frame. They must remain independent of each other except for a silicone bond.

The ¼" gaps could be covered with 1½" wide battens screwed to one board and bonded with silicone to the other. Or for a more authentic look press a natural rope, such as hemp or jute into wet silicone to fill the gap and bond the rope in place.

There are challenges such as cutting out for the lockset mortise and hinges but I think the look could be quite attractive and in line with what you had in mind.

So sorry I didn't see your reply till now. Thank you for all this thought you put into it! So very kind of you. I think what we are going to do is replace it with a wood-look fiberglass door that will hold up better to the extreme environment and future floods that are bound to reoccur.

Your idea sounds like it would work well and would allow for a lot of expansion and contraction. With me gluing all the pieces together, I don't know how I would be able to get it all apart without destroying it though. I figured surely there must be a good way to create a board and batten design of old, as that is what was there before, though a more simple design (no diagonals), and thicker boards. I guess using titebond and gluing everything was my biggest mistake and also screwing the two sides together in the manner I did. I like your idea of silicone as a way to seal out the elements. It would be much more flexible than the glue. Thanks again for all your thoughts!

It's very attractive, but as Esch said, doomed to failure. There is no structural fram, just a decorative frame applied to the outside only. You really can't save it.

You could build something that looks similar. You'd need a sold 1-3/4" mortise and tenon frame, and you could make diagonal panels within that.

You did not really build a frame to capture the panels as would have been done in the design book. The panels are never to be glued in a frame and panel door, there is a groove in the frame that receives the panel edges and the panel is allowed to expand and contract without constraint. In your case, the wood expanded and pushed the corners out, if it would have retracted, it would have cracked somewhere and pulled the corners in.

This forum post is now archived. Commenting has been disabled