Cupping norms, planing cups and re-cupping

Greetings

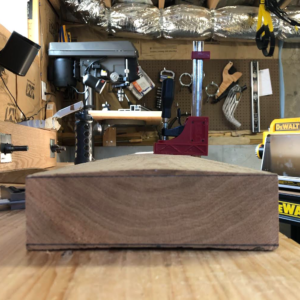

I went to my local lumberyard yesterday and they aren’t letting you pick out your own stock (can’t get out of the car). So I asked the guy to get me an 8/4 piece of oak, 10” wide and 6’-8’ feet long. I told him I’d rather have a narrower board if the 10” wide ones were really cupped. He got me a 7” wide one (attached I hope).

1. How much cupping is too much? Measuring from the line to the top of the board, it’s 3/16”. While it would be nice to have no cup, I don’t have the experience to know what I can reasonably expect. It seems like a lot but I don’t know.

2. While I would love to make this more difficult than it has to be, can I just run this through the planer a few times to flatten the top face, then flip and repeat? When I press on it, it doesn’t rock, and it seems the cup is fairly symmetrical.

3. Let’s say I want to make shelves, and I resaw 1/4” slices. Is that going to cup again?

thanks!

w2

Replies

If you have a jointer, it would be better to flatten the concave surface on that and then put it through the planer. Otherwise, yes, I have flattened boards like that on the planer, putting the concave side down until the convex side is flat or at least mostly flat (to avoid rocking when you flip it).

If you resaw any wood, it can can cup again. You should sticker the cut pieces for at least a day. I've seen advice anywhere from one day to two weeks. I'd check each day; if you haven't seen any cupping after 5 days, you're probably good. Likely there will be a bit, though, and you'll have to repeat the process. Since the second time you won't be taking much off and the wood is already near size, the cuts should be light (less than .05") and you can probably work the wood straight off. Of course, this means your resawing should leave enough for the second flattening.

One thing, though. After you sticker it for the first time, sight the length of the board and make sure it's not developed a twist on top of the cupping. If the board is twisted in the wrong way, it may not play well in the planer and you'll have to do some hand planing to get one side to sit flat on the bottom surface of the planer.

When you buy 8/4 hardwood lumber, it is expected that you get 1 3/4´´ when surfaced 2 sides after drying. That’s what limits cupping.

If you don't have a jointer you can resaw the convex side off at tge bandsqw to get it flat enough to run through the planer. If you just run it through as it is the feed rollers can flatten it out, leaving you with a thinner cupped board. If you resaw through the center you can run both through the planer. Since you are aiming for 1/4" slices that may get you the most finished stock.

These are strange times we live in. Before they completely closed our lumber stores, we did the drive up thing as well. Be polite, but it's OK to reject the lumber they bring out. If you wouldn't pick it, don't feel obligated to take the lumber you aren't happy with.

Where are you guys?

I’m south of Boston. Thanks for the replies, all good advice. I don’t have a jointer and the bandsaw is new for me, so I’ll probably take that route (good for learning). Seems to make sense and would save my planer blades some.

I'm in NYC and you can still stroll into a Home Depot. F'd ^ if you ask me. This is gonna be a while.

Hey Weymouth, I'm about 5 miles away. I made a final trip to Highland Hardwoods about 4 days before they closed to pick out enough lumber to last the duration.

I don't have a jointer, and have never missed it. I would never consider using a bandsaw to remove a little bit of cup. Way too much work, way too inaccurate on rough lumber, and you are likely to muck it up more.

Your board is extremely typical. As someone above said, run it through your planer, concave side down, until the convex side is mostly flat. Then do the flip side. If you have a lot to remove, don't take most of the stock off one side. Try to remove about equal amounts from both faces.

I've never rejected a board for cupping. Twist is another matter. Too much twist is not worth dealing with, and is more likely to cause trouble down the line.

We all want perfectly straight and flat lumber, but wood is wood. That is probably an acceptable amount of cupping, but it depends on what you're doing with the lumber.

If you're looking for a 1 3/4" board you'll be ok, but if you are resawing it, you're going to have issues. First, it is a flat sawn board, second highly likely there is stress built in.

Third, kiln dried 8/4 lumber from a supplier is risky due to high probability of case hardening (outside dried to quickly). This is because commercially kiln dried lumber is moved out to quickly and run up too high a temp.

If this is the case, it will be immediately apparent as you watch the wood cup right off the saw.

IMO 8/4 lumber and above is best either air dried or lengthy kiln drying.

This forum post is now archived. Commenting has been disabled